Multifunctional composite chemical fertilizer treatment equipment

A processing equipment and composite technology, applied in chemical/physical processes, mixers, mixing methods, etc., can solve the problem of inability to take into account the mixing and stirring of granular fertilizers and liquid fertilizers, such as dissolving and stirring, to save working time, achieve continuity, The effect of stirring evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

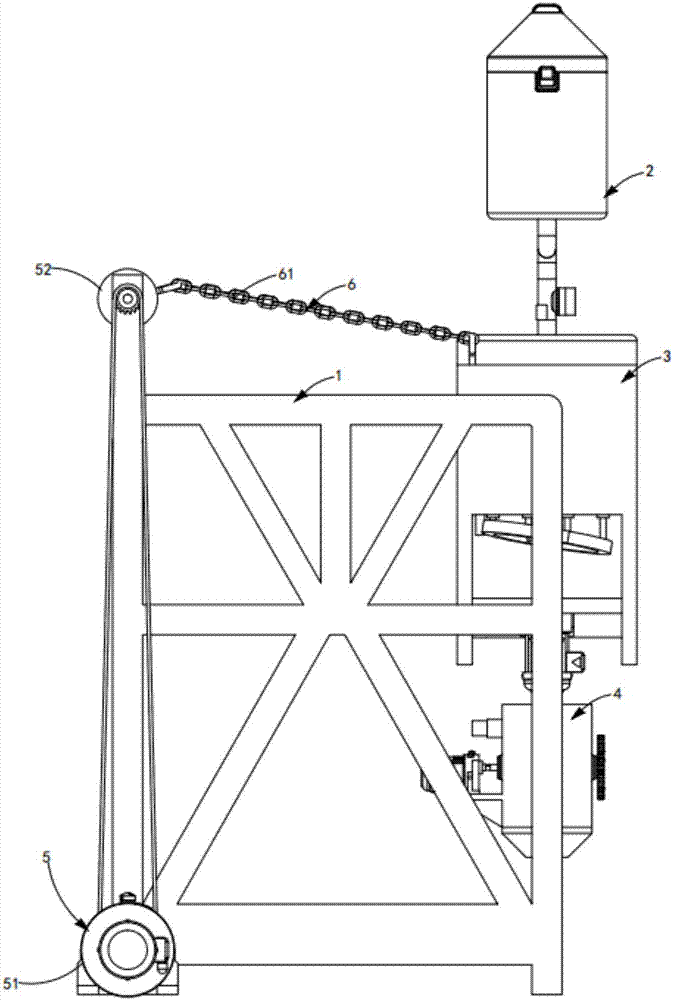

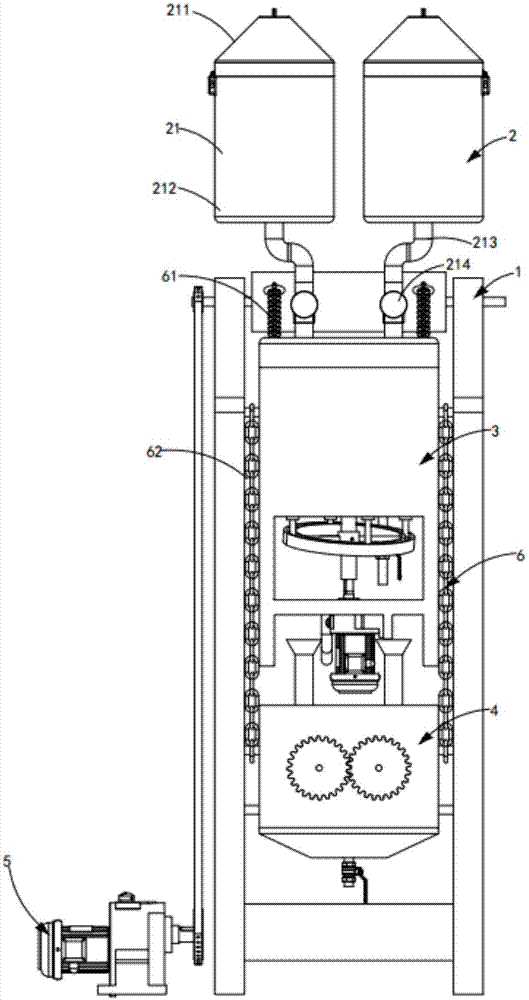

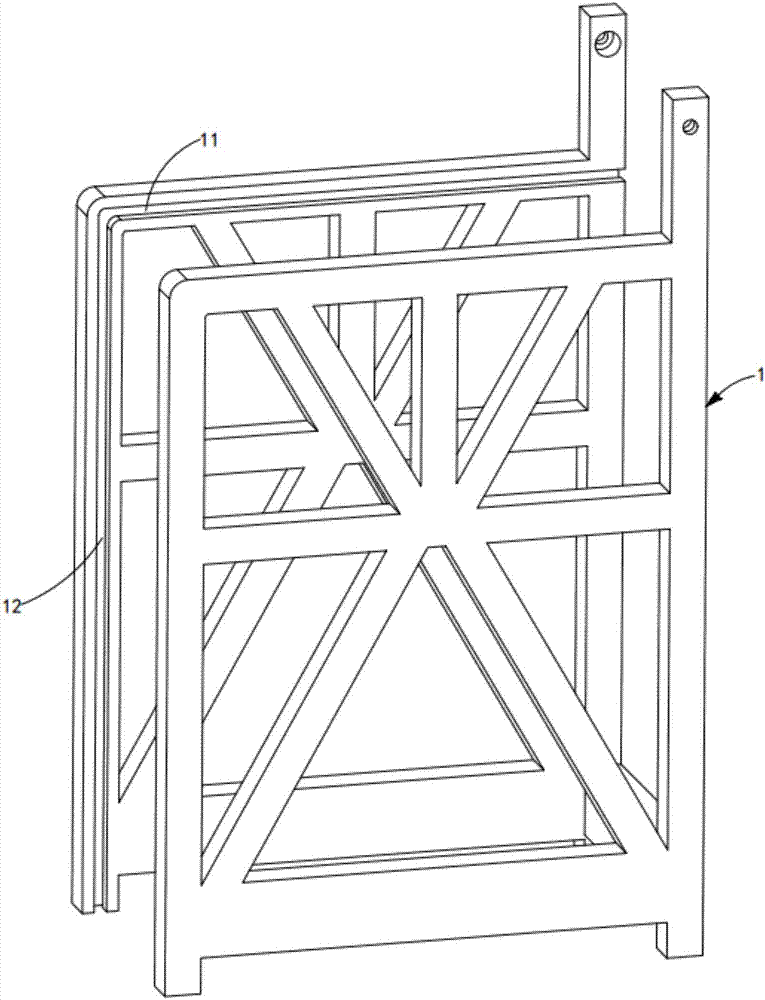

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a multifunctional compound fertilizer processing equipment, a multifunctional compound fertilizer processing equipment, includes a frame 1, a bucket assembly 2, a mixing assembly 3, a dissolving agitation assembly 4, a traction assembly 5 and a connection Assembly 6, the frame 1 is provided with a horizontal chute 11 and a longitudinal chute 12; the bucket assembly 2 is provided on the front side of the frame 1, and the mixing assembly 3 is connected directly below it. The mixing and stirring assembly 3 can slide horizontally along the transverse chute 11, and the dissolving and stirring assembly 4 is arranged directly below the mixing and stirring assembly 3, and the dissolving and stirring assembly 4 can slide longitudinally along the longitudinal chute 12, and the pulling The assembly 5 is arranged on the rear side of the frame 1, and the connecting assembly 6 is used to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com