Bookbinding-type stationery comprehensive tester and test method thereof

A comprehensive tester and stationery technology, applied in the testing of machine/structural components, instruments, measuring devices, etc., can solve problems such as errors, frequent nail changes, and cumbersome paper changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

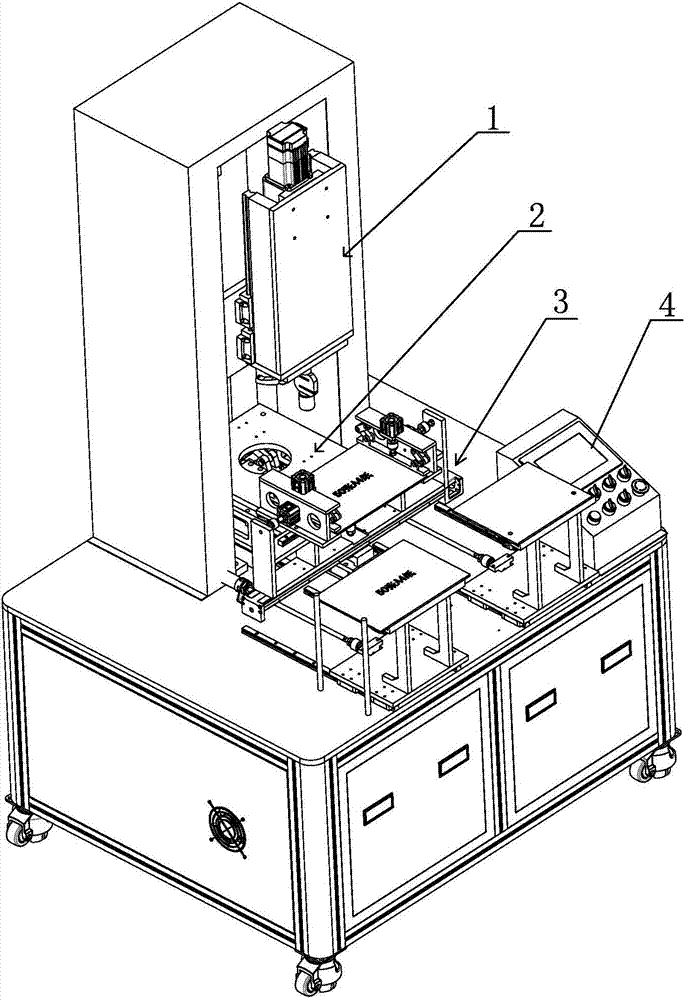

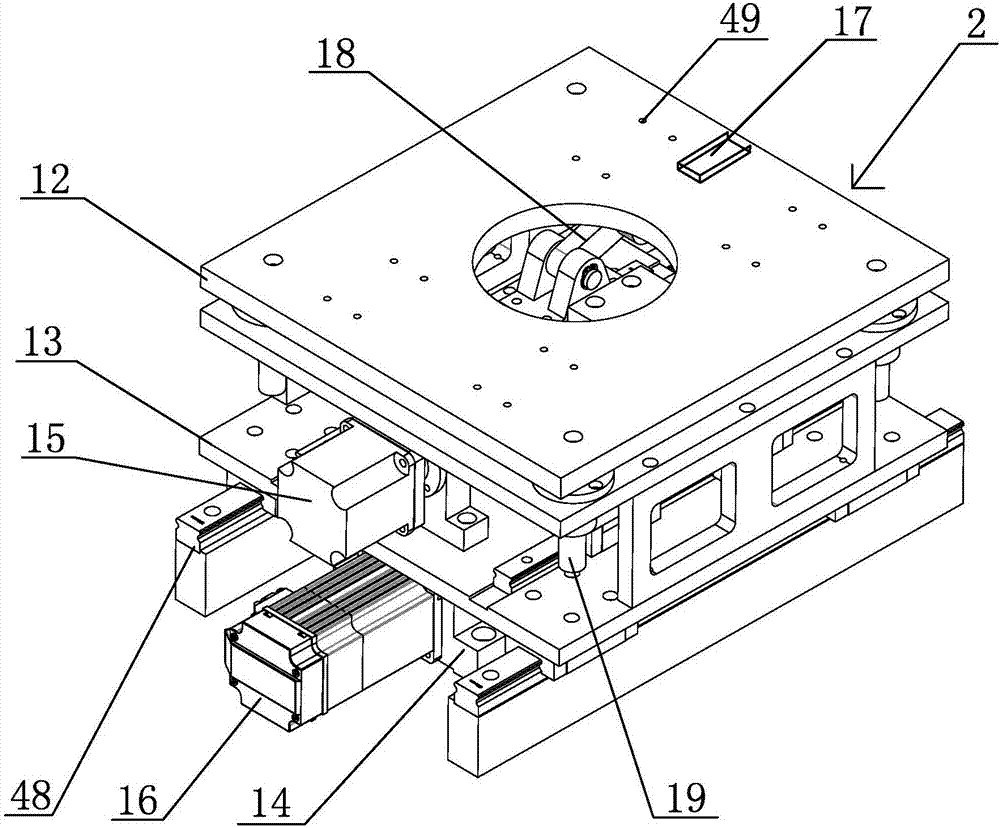

[0047] A comprehensive tester for binding stationery, such as figure 1 As shown, it includes a force loading mechanism 1 for applying pressure to the sample, a sample fixing mechanism 2 located below the force loading mechanism 1, a paper feeding mechanism 3 located in front of the sample fixing mechanism 2, and a data output screen 4 connected to a computer;

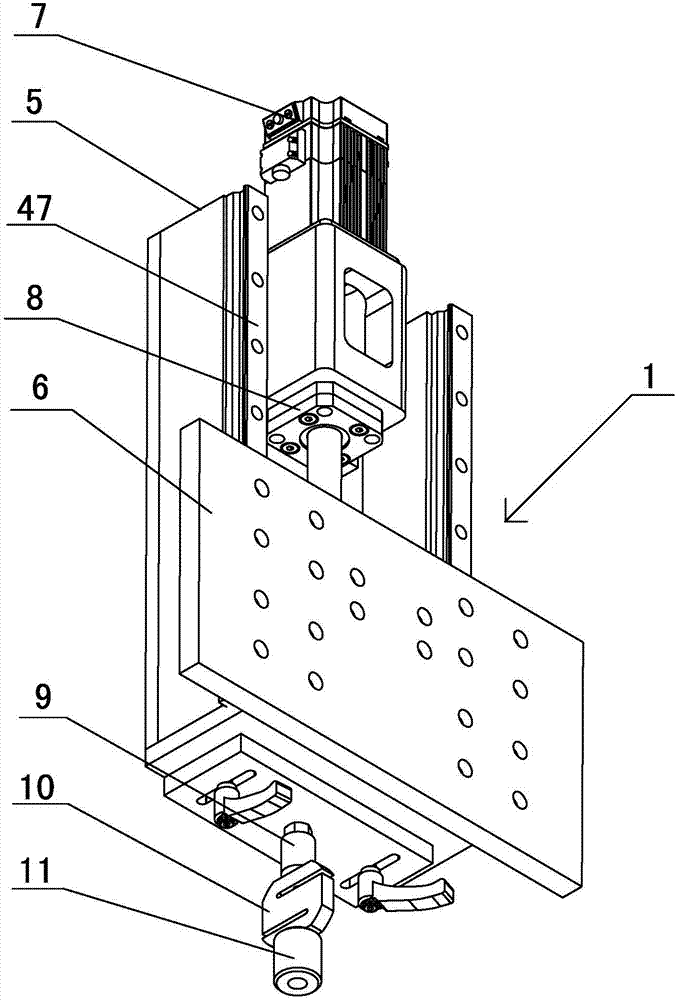

[0048] like figure 2 As shown, the force loading mechanism 1 includes a U-shaped longitudinal fixing plate 5 in cross section and a longitudinal receiving plate 6 parallel to the front end of the longitudinal fixing plate 5. The upper part of the longitudinal fixing plate 5 is provided with a first servo motor 7. The longitudinal receiving plate The inner surface of 6 is fixedly provided with a first screw transmission mechanism (such as Figure 7 As shown), the first screw transmission mechanism is connected with the first servo motor 7, the center of the inner surface of the longitudinal receiving plate 6 is fixedly...

specific Embodiment 2

[0058] The test method of the binding class stationery comprehensive tester described in the above-mentioned specific embodiment 1 comprises the following steps:

[0059] (1) Pre-set the loading pressure and establish three-dimensional coordinates. The initial setting is centered on the sample clamping mold 17, the left and right direction is the X axis, the front and rear direction is the Y axis, and the vertical direction is the Z axis. Specifically: turn on the second servo The motor 15 drives the sample fixing platform 12 to move along the Z-axis direction through the first crank connection mechanism 18; the third servo motor 16 is turned on, and the horizontal receiving plate 13 is driven to move backward along the Y-axis direction through the second screw transmission mechanism, thereby driving and The sample fixing platform 12 fixedly connected to the horizontal receiving plate 13 moves along the Y-axis direction until the sample clamping mold 17 reaches the preset initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com