Uniparted hyperboloid coring and chambering rock-plug blasting method

A hyperboloid, core hole technology, used in drilling equipment and methods, blasting, earthwork drilling, etc., can solve the problems of lack of penetration, unable to meet the core and penetration of rock plugs, etc., to reduce the initial explosion pressure, reduce over crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

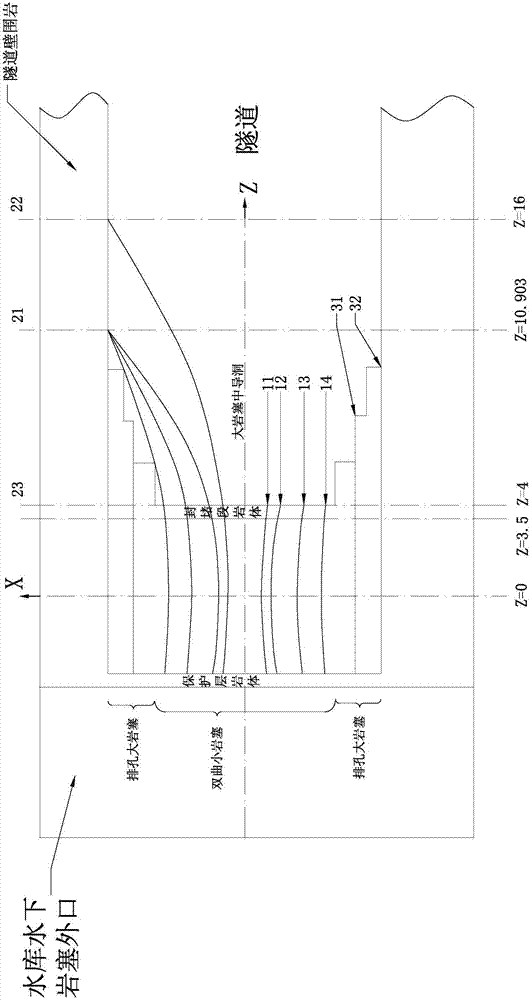

[0089] According to the existing Changdian project research, a large-scale rock plug blasting plan with a full row of holes and deep holes with a central pilot tunnel is adopted. Through the productive blasting test of the full-section rock plug in the water diversion tunnel, the medium pilot tunnel is constructed first, and the small rock plug is blasted when the rock plug is blasted. The blasting of parallel dense rows of holes (3 meters deep) first penetrated, the big rock plugs were blasted sequentially from the inside to the outside, and finally the construction blasting plan of smooth surface blasting of the surrounding holes was successful.

[0090] Jilin Yinsong can graft the hyperbolic technology to the Changdian technical solution, such as figure 1 As shown, the middle pilot hole is drilled and blasted every half meter from the outside to the inside, and the diameter is reduced step by step to form a symmetrical step-shaped adjustment, so as to facilitate the hyperbol...

Embodiment 2

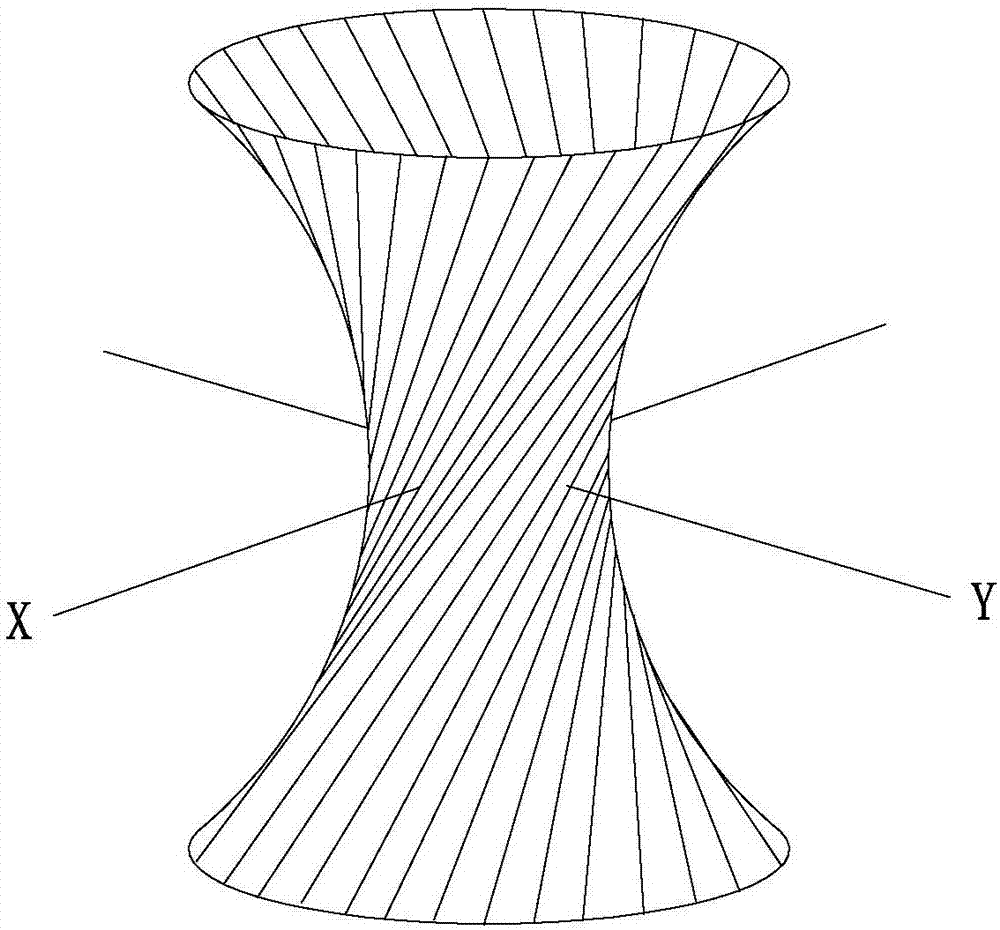

[0096] According to the tunnel drilling and blasting construction calculation, the main hyperboloid surface equation of the 8-meter-thick pure hyperbolic rock plug blasting for the loosening case is:

[0097]

[0098] In addition, the following relevant technical requirements for the rock plug hyperbolic coring-through method of the present invention are provided.

[0099] 1. Ensure that the core of the rock plug is penetrated

[0100]In order to ensure the penetration of the single-leaf hyperbolic coring of the rock plug, the main hyperbolic coring body is strictly symmetrically arranged and blocked to ensure the symmetrical coring of the hyperbolic two directions. Rock plug coring should be charged at the upstream end according to the water head and self-weight increment, which can be increased by 20% to 30% according to the charge increment ratio of underwater blasting. Thickness; a more accurate expression is that the tensile shear strength of the rock mass in the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com