Marine LNG/diesel oil dual-fuel engine safety monitoring system

A dual-fuel engine and safety monitoring system technology, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problem of scattered ship engine monitoring items, unfavorable operators, dual-fuel engine related equipment monitoring and management, simple monitoring logic, etc. problems, to achieve the effect of convenient analysis and processing, and accurate safety monitoring data reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the structure and function of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

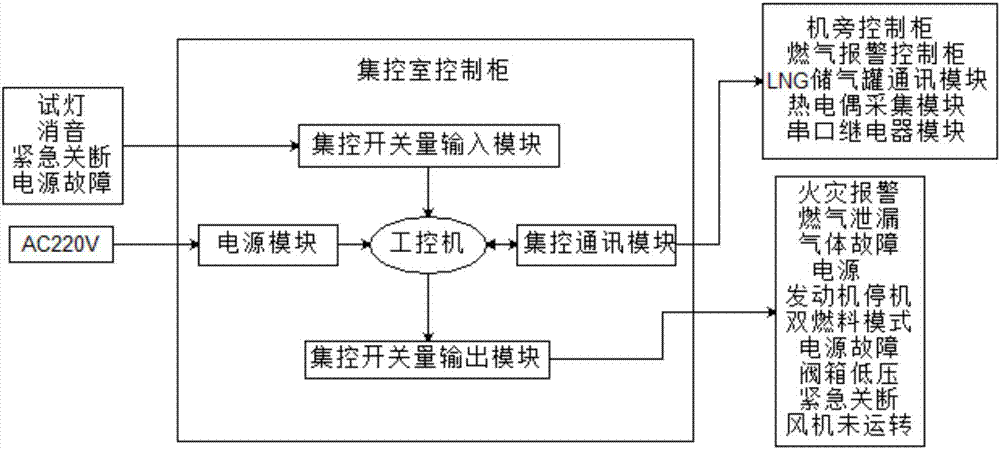

[0021] like figure 1 As shown, the hardware of the present invention includes a programmable logic controller (PLC) 5, a gas alarm controller 3, a LNG storage tank communication module 6, a thermocouple acquisition module 4, a serial port relay module, USB to RS485 converter. The industrial computer adopts Modbus communication mode to build a communication network with programmable logic controller (PLC) 5, gas alarm controller 3, LNG gas storage tank communication module 6, thermocouple acquisition module 4, and serial port relay module for data exchange.

[0022] like figure 2 As shown, the industrial computer uses Kingview as the monitoring software and runs related monitoring controls. Modbus communication mode is adopted, and KingView, as the master station, will regularly se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com