A reducing die pipe device and diameter reducing method for easy casting and demolding

A technology for mold pipes and pipes, which is applied in the fields of mold shells/templates/work frames, erection/assembly of bridges, and on-site preparation of building components, etc. The overall structure is simple and the design is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

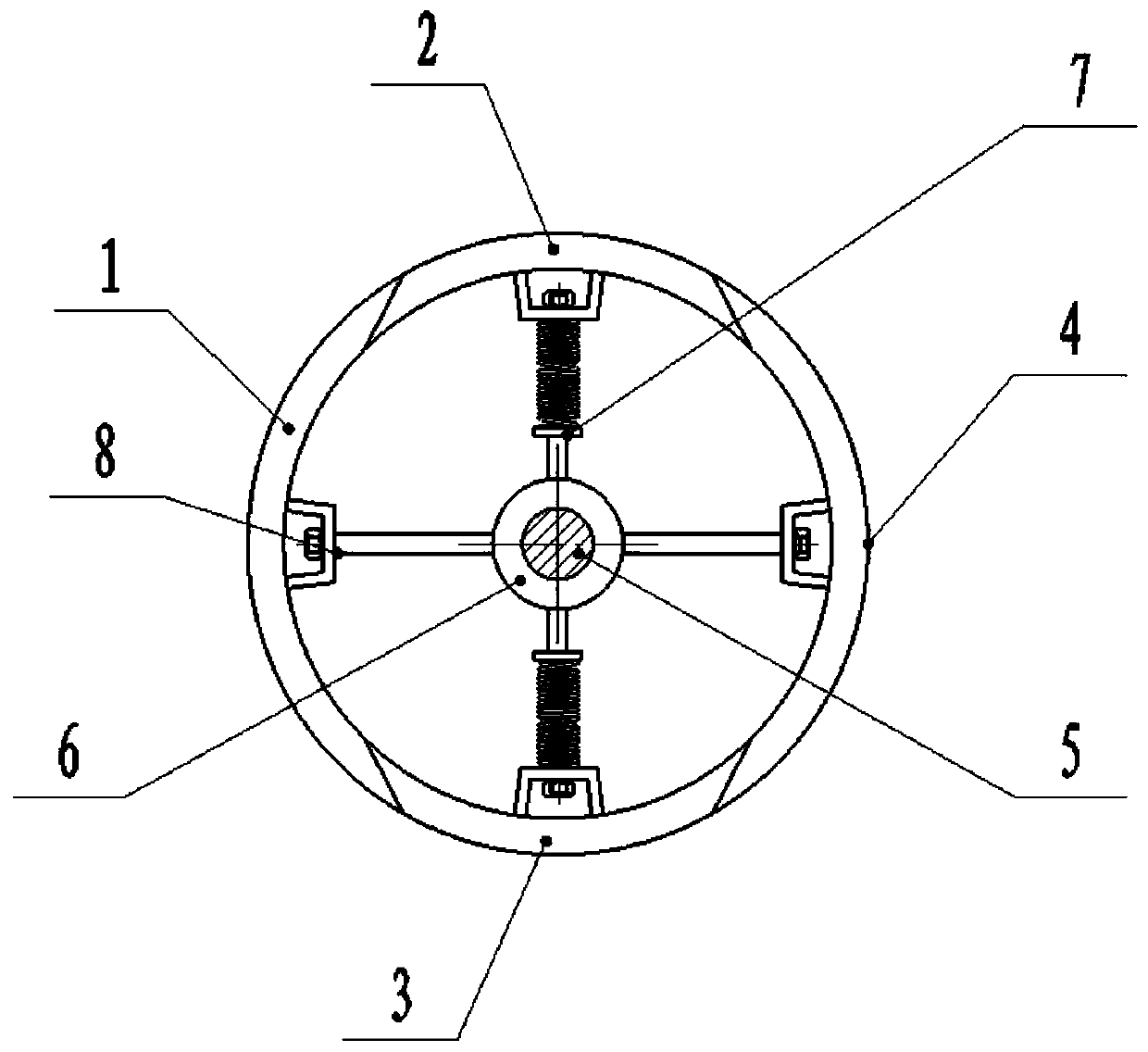

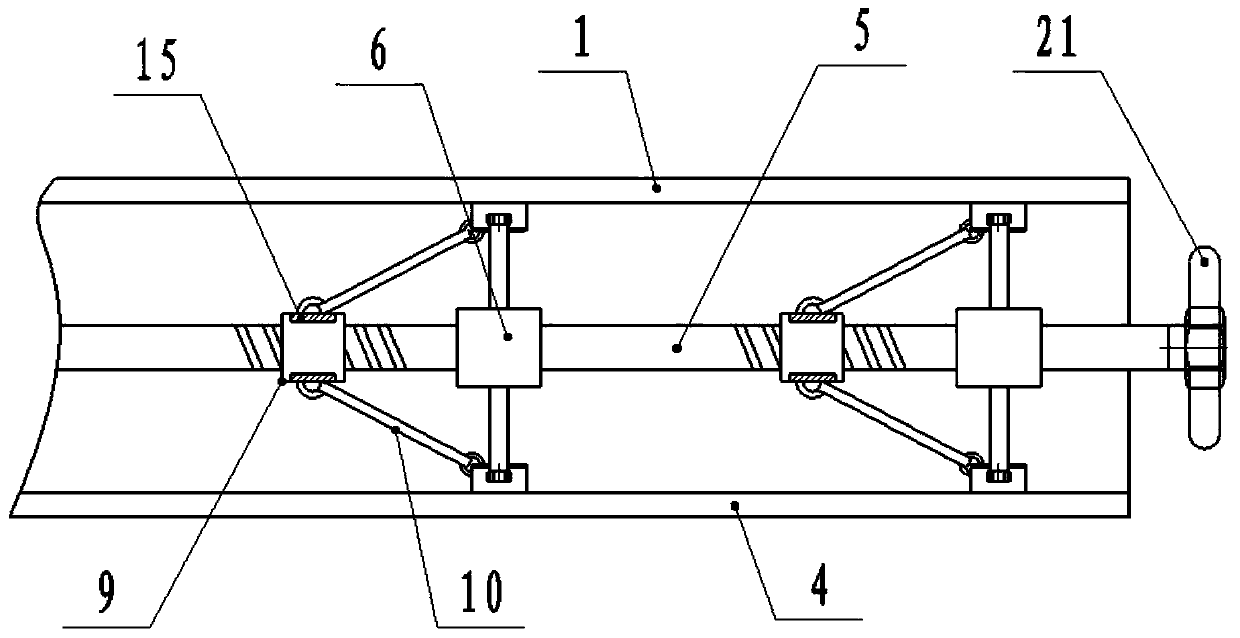

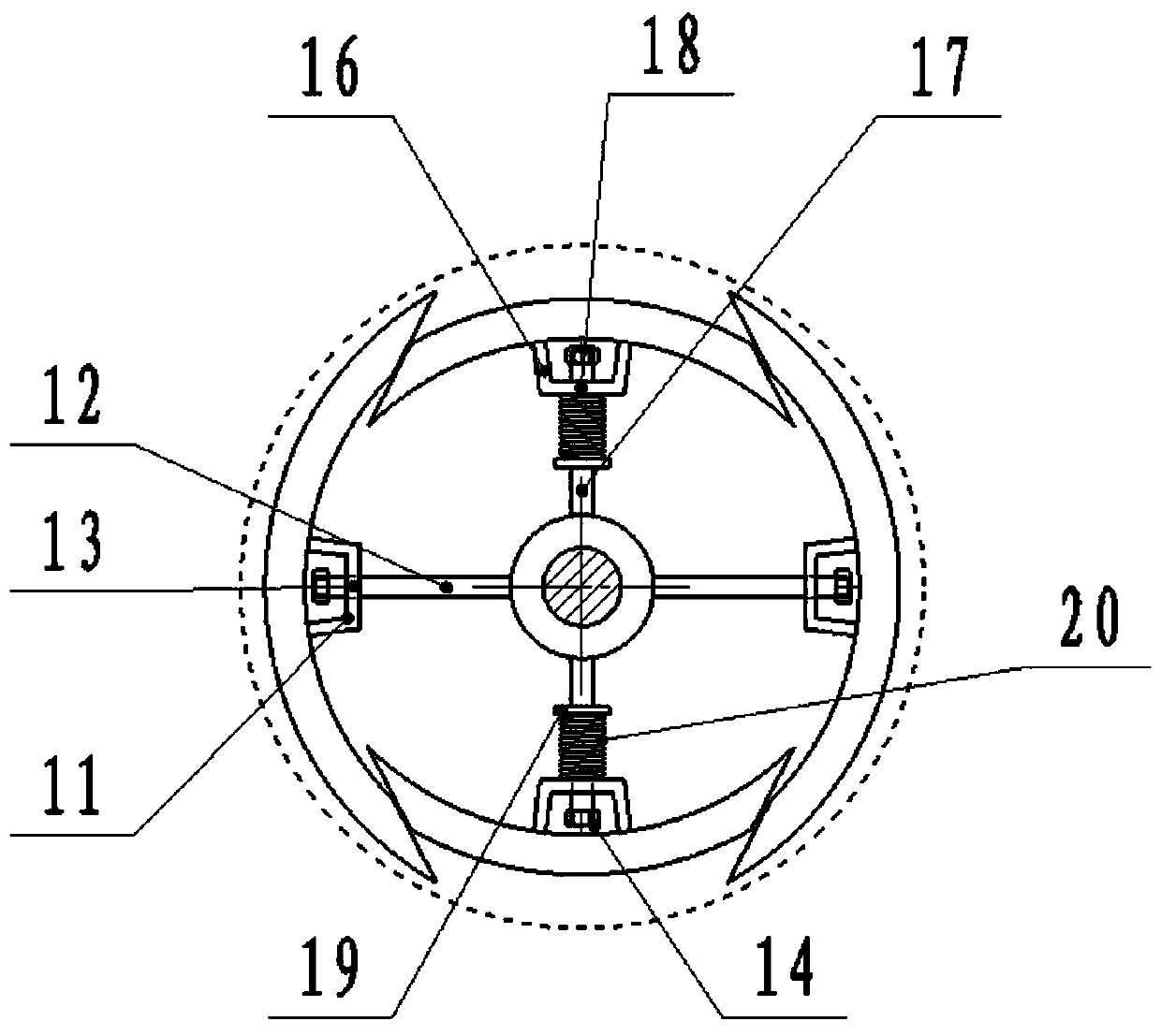

[0029] Such as Figure 1-3 As shown, the present invention is a variable-diameter mold pipeline device that is convenient for pouring and demoulding, including a mold pipeline, and the mold pipeline is cut into two symmetrical four-piece pipeline segments along the axial direction, which are respectively the first pipeline sector 1, the second The pipe segment 2, the third pipe segment 3 and the fourth pipe segment 4, the two sides of the first pipe segment 1 and the corresponding sides of the second pipe segment 2 and the third pipe segment 3 adopt oblique faces, and the fourth pipe segment The two sides of the fan piece 4 and the corresponding sides of the second pipeline fan piece 2 and the third pipeline fan piece 3 also adopt oblique faces, and the center of the mold pipeline is provided with a rotating shaft 5. When the mold pipeline is 2m long and the diameter is 0.2m, the rotating shaft 5 Four shaft sleeves 6 are evenly distributed on the top, which can be flexibly ope...

Embodiment 2

[0036] Such as Figure 1-3 As shown, a method for reducing the diameter of mold pipes of the present invention, which is convenient for pouring and demoulding, comprises steps:

[0037] Step 1) Reversely rotate the rotating shaft 5 by the hand wheel 21, so that the first pipe segment 1, the second pipe segment 2, the third pipe segment 3 and the fourth pipe segment 4 are reset to form a complete mold pipe;

[0038] Step 2) After the pouring is completed, when the mold pipe needs to be taken out, the rotating shaft 5 is rotated forward by the hand wheel 21, and the rotation of the rotating shaft 5 drives the wire sleeve 9 and the sliding sleeve 15 on the wire sleeve 9 to move down along the rotating shaft 5, and the sliding sleeve 15 Pull the first U-shaped buckle 11 through the connecting shaft 10 to move along the first guide shaft 12 to the axial direction of the mold pipe, and through the pulling of the first U-shaped buckle 11, the first pipe segment 1 and the fourth pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com