A device and method for monitoring target material consumption

A technology of target material and condition, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problem that the target material cannot be found in time, avoid the problem of target material breakdown, and improve the efficiency of target material use , The effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

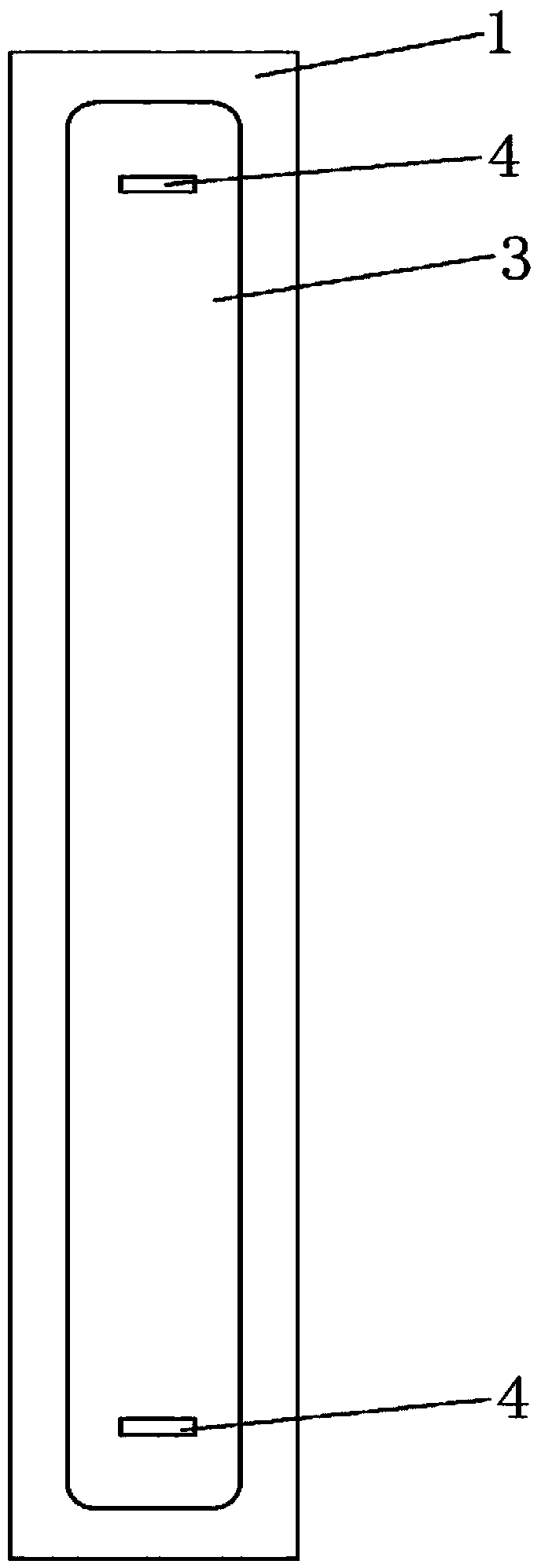

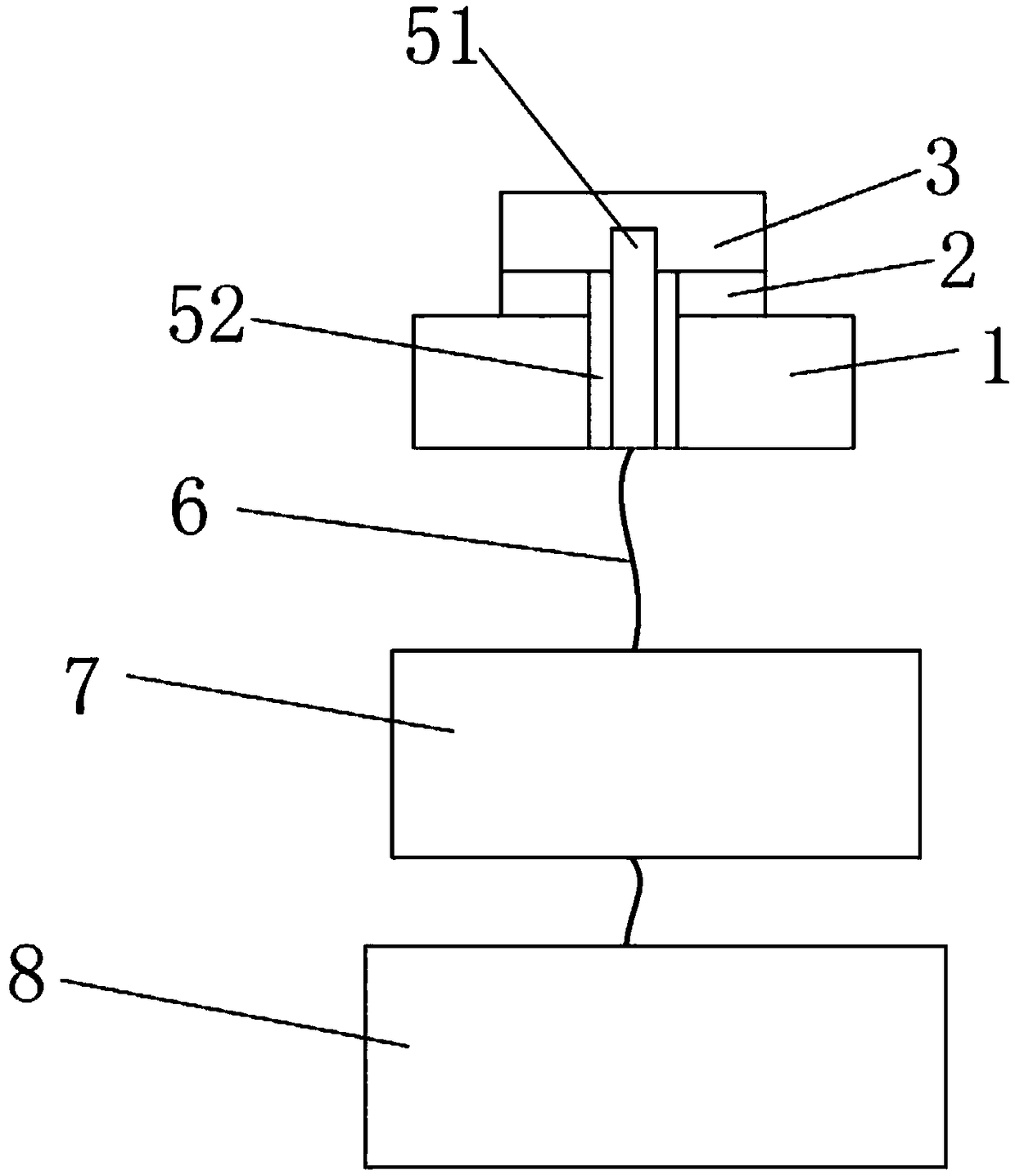

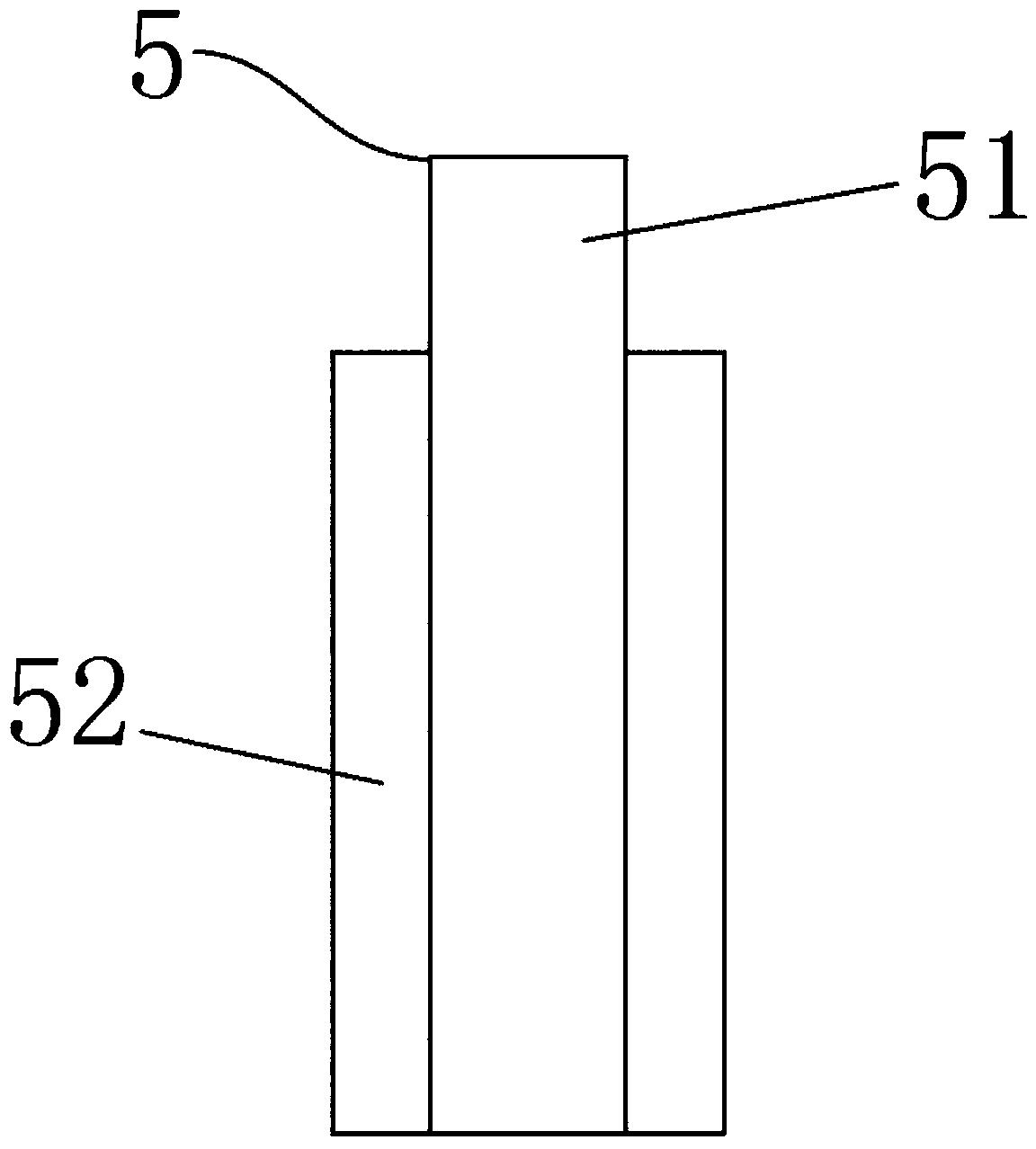

[0028] Such as figure 1 with figure 2 As shown, it is a top view of the device for monitoring target consumption status and a cross-sectional view of the device for monitoring target consumption status of the present invention, respectively: it includes: a target back plate 1 and a target material 2, and the target material is adhered by an adhesive layer 3 connected to the target back plate 1. A loop component (drawn in the figure), when the target is not consumed to a specified level, the loop component can form a complete loop with the target, when the target is consumed to a specified level, the The loop assembly cannot form a complete loop with the target. With such an arrangement, it is possible to detect the degree of target material consumption in time when the circuit cannot be formed, and it is convenient to replace the target material.

[0029] Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com