A ceramic tile surface glaze with high whiteness and preparation method thereof

A ceramic tile, high whiteness technology, applied in the field of ceramic tile glaze, can solve the problem of not appearing ideal, and achieve the effects of good post-processing performance, close color and good luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

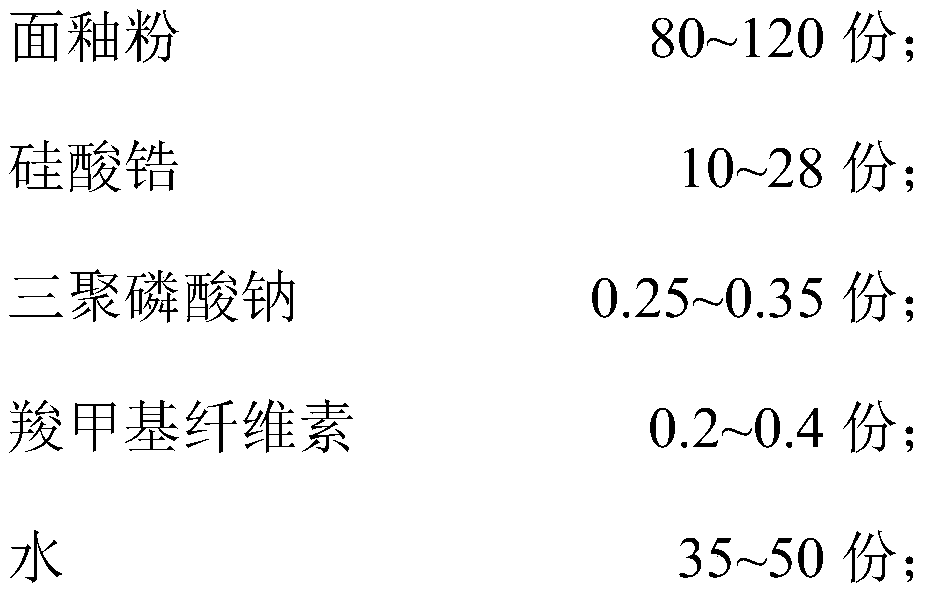

[0024] A ceramic tile surface glaze with high whiteness, which is composed of the following raw material components in parts by weight:

[0025]

[0026] Wherein, the glaze powder includes the following raw material components in parts by weight:

[0027]

[0028] The potassium sodium stone powder is formed by mixing potassium feldspar and albite at a ratio of 1:1 by weight; the quartz powder is high-purity quartz powder with a purity of 98% to 99%; the alumina is α- Aluminum oxide; the chemical composition of the glaze: SiO 2 : 55.47%, Al 2 o 3 : 27.24%%, Fe 2 o 3 : 0.05%, TiO 2 : 3.21%, CaO: 4.69%, MgO: 0.64%, K 2 O: 1.94%, Na 2 O: 2.60%, ZnO: 1.0%, loss on ignition: 3.14%; the zirconium content in the zirconium silicate is not more than 24.5% of the total weight of the surface glaze raw materials; the carboxymethyl cellulose is a high-viscosity methyl group, its The viscosity is greater than 300mPa.s.

[0029] Preparation:

[0030] Mix the raw material compo...

Embodiment 2

[0033] A ceramic tile surface glaze with high whiteness, which is composed of the following raw material components in parts by weight:

[0034]

[0035] Wherein, the glaze powder includes the following raw material components in parts by weight:

[0036]

[0037]

[0038] The potassium sodium stone powder is formed by mixing potassium feldspar and albite at a ratio of 1:1 by weight; the quartz powder is high-purity quartz powder with a purity of 98% to 99%; the alumina is α- Aluminum oxide; chemical composition of the glaze: SiO 2 : 52.57%, Al 2 o 3 : 24.32%%, Fe 2 o 3 : 0.05%, TiO 2 : 7.15%, CaO: 7.14%, MgO: 0.57%, K 2 O: 1.74%, Na 2 O: 2.32%, ZnO: 0.89%, loss on ignition: 2.81%; the zirconium content in the zirconium silicate is not more than 24.5% of the total weight of the surface glaze raw materials; the carboxymethyl cellulose is a high-viscosity methyl group, its The viscosity is greater than 300mPa.s.

[0039] Preparation:

[0040] Mix the raw materia...

Embodiment 3

[0043] A ceramic tile surface glaze with high whiteness, which is composed of the following raw material components in parts by weight:

[0044]

[0045] Wherein, the glaze powder includes the following raw material components in parts by weight:

[0046]

[0047] The potassium sodium stone powder is formed by mixing potassium feldspar and albite at a ratio of 21:22 by weight; the quartz powder is high-purity quartz powder with a purity of 98% to 99%; the alumina is α- Aluminum oxide; the chemical composition of the glaze powder: SiO 2 : 53.27%, Al 2 o 3 : 23.19%%, Fe 2 o 3 : 0.05%, TiO 2 : 7.67%, CaO: 7.22%, MgO: 0.79%, K 2 O: 2.03%, Na 2 O: 2.74%, ZnO: 0.83%, loss on ignition: 2.22%; the zirconium content in the zirconium silicate is not more than 24.6% of the total weight of the surface glaze raw materials; the carboxymethyl cellulose is a high-viscosity methyl group, its The viscosity is greater than 300mPa.s.

[0048] Preparation:

[0049] Mix the raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com