Linear worm wheel elevator

A worm gear and linear technology, applied in the field of mechanical technology, can solve the problems of trapped passengers, unable to protect people, and useless elevators, etc., to achieve the effects of prolonging service life, flexible and convenient application, and easy installation, commissioning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

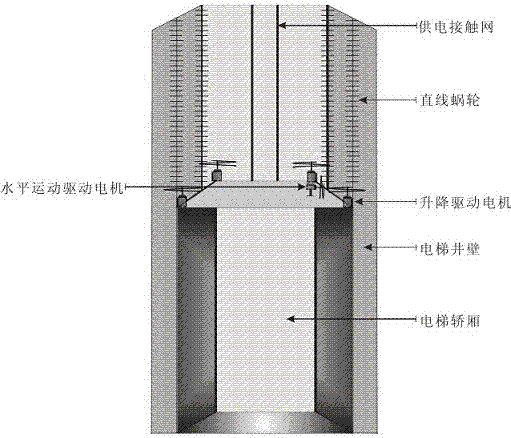

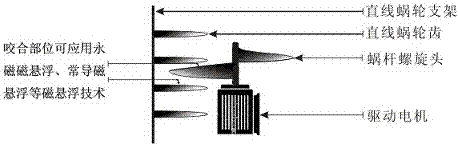

[0006] The linear worm gear elevator uses the worm screw head and the linear worm gear teeth to mesh with each other, and the motor drives the worm to rotate. Through the cooperation with the linear worm gear, the rotation of the motor is converted into a vertical lifting motion to drive the elevator car up and down. Conversely, the lifting of the elevator car must be converted into the rotation of the worm, so this driving method can provide absolute safety and ensure that the elevator car cannot fall freely. Changing the contact area between the worm screw head and the teeth of the linear worm gear, the number of heads of the worm screw head, and the number of groups of the worm screw and the linear worm gear can all change the load-carrying weight of the elevator car. All driving, control, backup power supply, monitoring and other systems are all concentrated on the elevator car, and the brushes are used to obtain power from the external power supply catenary. The external p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com