High-speed concrete transportation equipment

A technology for transporting equipment and concrete, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of increasing investment costs, clumsy hopper production, and increasing production costs, reducing production investment and production costs, improving Production site environment, the effect of improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

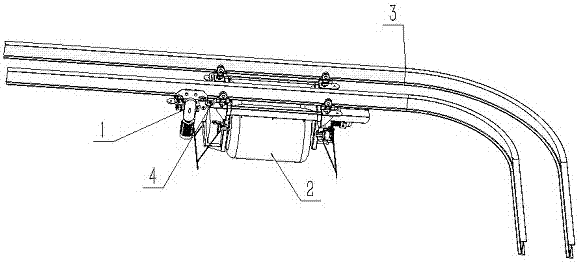

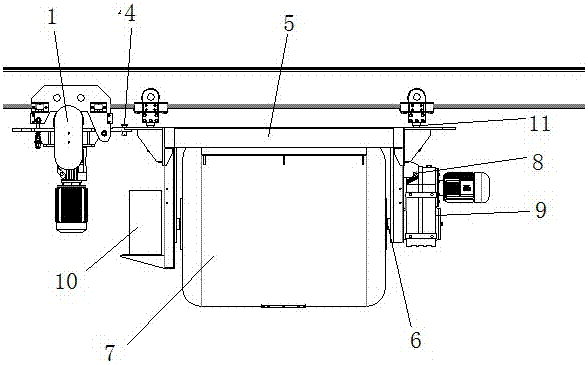

[0012] This invention technology will be further described below in conjunction with accompanying drawing:

[0013] As shown in the figure, a concrete high-speed transportation equipment includes a power unit 1, a high-speed shuttle conveyor 2, and a running track 3. It is characterized in that the high-speed shuttle conveyor 2 is based on a main frame 5, and A power distribution cabinet 10 is installed on one side of the frame 5, and the rotary drive reducer 9 is fixed on the other side of the main frame 5 through the fixed pin 8 of the rotary drive reducer, and the rotary spindle 6 passes through the axis of the storage tank 7 and the storage tank 7 connected as a whole (welding process or flange connection can be used ) And be fixed on the main frame 5, one end of the rotating main shaft 6 is connected with the rotating drive reducer 9, the storage tank 7 and the rotating main shaft 6 complete the rotation action under the effect of the rotating driving reducer 9, the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com