Particle coal classified flotation machine

A flotation machine and sorting technology, which is applied in flotation, solid separation, etc., can solve the problems of poor sorting effect and narrow sorting range, and achieve the effect of thorough sorting, good sorting effect and less waste in coal mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

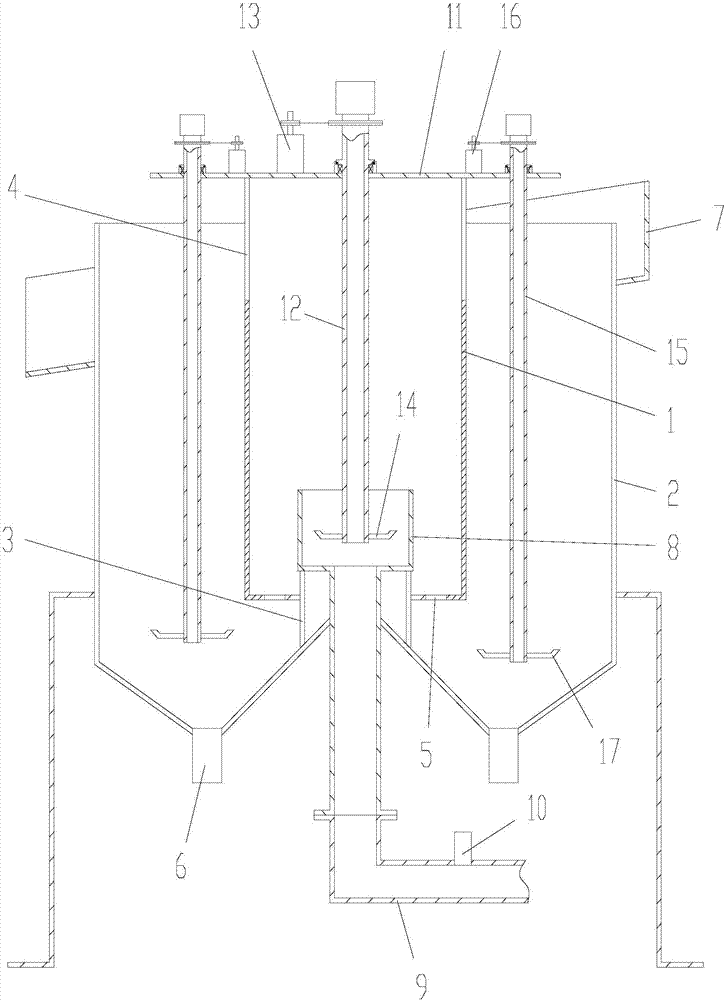

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] As shown in the figure, the granular coal classification flotation machine of this embodiment includes a primary separation tank 1 and a secondary separation tank 2 coaxially arranged outside the primary separation tank, and the bottom of the secondary separation tank An annular plate support plate 3 fixedly connected to the bottom of the first-level sorting tank is arranged in the middle; a gap groove 4 is provided around the upper end of the first-level sorting tank to allow the foam to flow into the second-level sorting tank, and the first-level sorting tank The bottom is provided with a coal slurry outlet 5, and the coal slurry outlet is located on the outside of the annular support plate; the bottom of the secondary separation tank is provided with a slag outlet 6, and the upper periphery of the secondary separation tank is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com