An impeller for hydroelectric power generation

An impeller and water conservancy technology, applied in the field of water conservancy equipment and hydropower generation, can solve the problems of left and right shaking, small dead weight, high maintenance rate, etc., and achieve the effect of stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An impeller for hydroelectric power generation, including an impeller shaft and impeller blades;

[0029] One end of the impeller shaft is connected to the top bearing, the other end is connected to the end bearing, and is coaxially connected to the transmission shaft at the end.

[0030] There are 5 impeller blades, all of which take the entire length of the impeller shaft as the contact part and extend outward in an arc shape, and the width of each impeller blade gradually increases from the top of the impeller shaft to the width at the end of the impeller shaft widest.

[0031] Inside the arc of each impeller blade, a speed reduction plate is arranged in reverse. The speed reduction plate includes a root portion of the speed reduction plate and a head portion of the speed reduction plate. The root portion of the speed reduction plate is fixedly connected to the impeller blade. The width of the root of the speed reduction plate is greater than the width of the head o...

Embodiment 2

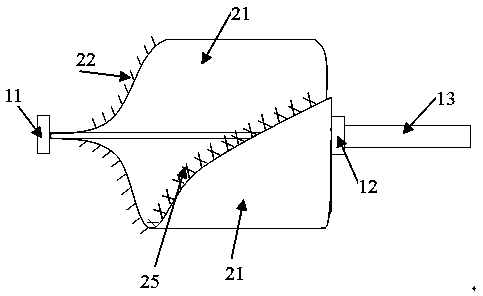

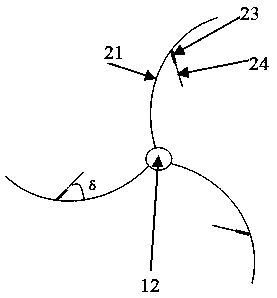

[0040] Such as Figure 1~Figure 3 shown.

[0041] An impeller for hydroelectric power generation, including an impeller shaft and impeller blades;

[0042] One end of the impeller shaft is connected to the top bearing, the other end is connected to the end bearing, and is coaxially connected to the transmission shaft at the end.

[0043] There are 3 impeller blades, all of which take the entire length of the impeller shaft as the contact part and extend outward in an arc shape, and the width of each impeller blade gradually increases from the top of the impeller shaft to the width at the end of the impeller shaft widest.

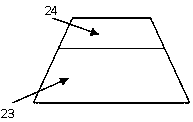

[0044] Inside the arc of each impeller blade, a speed reduction plate is arranged in reverse. The speed reduction plate includes a root portion of the speed reduction plate and a head portion of the speed reduction plate. The root portion of the speed reduction plate is fixedly connected to the impeller blade. The width of the root of the speed reduction ...

Embodiment 3

[0060] An impeller for hydroelectric power generation, including an impeller shaft and impeller blades;

[0061] One end of the impeller shaft is connected to the top bearing, the other end is connected to the end bearing, and is coaxially connected to the transmission shaft at the end.

[0062] There are 3 impeller blades, all of which take the entire length of the impeller shaft as the contact part and extend outward in an arc shape, and the width of each impeller blade gradually increases from the top of the impeller shaft to the width at the end of the impeller shaft widest.

[0063] Inside the arc of each impeller blade, a speed reduction plate is arranged in reverse. The speed reduction plate includes a root portion of the speed reduction plate and a head portion of the speed reduction plate. The root portion of the speed reduction plate is fixedly connected to the impeller blade. The width of the root of the speed reduction plate is greater than the width of the head o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com