Forged steel node building-steel-structure connecting method

A technology of structural connection and node connection, which is applied in the direction of building construction and construction, can solve the problems of high welding process requirements, strict manufacturing requirements, and difficult correction of welding deformation, so as to avoid welding deformation and correction, and solve the problems of connection and Soldering problems, easy connection and force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

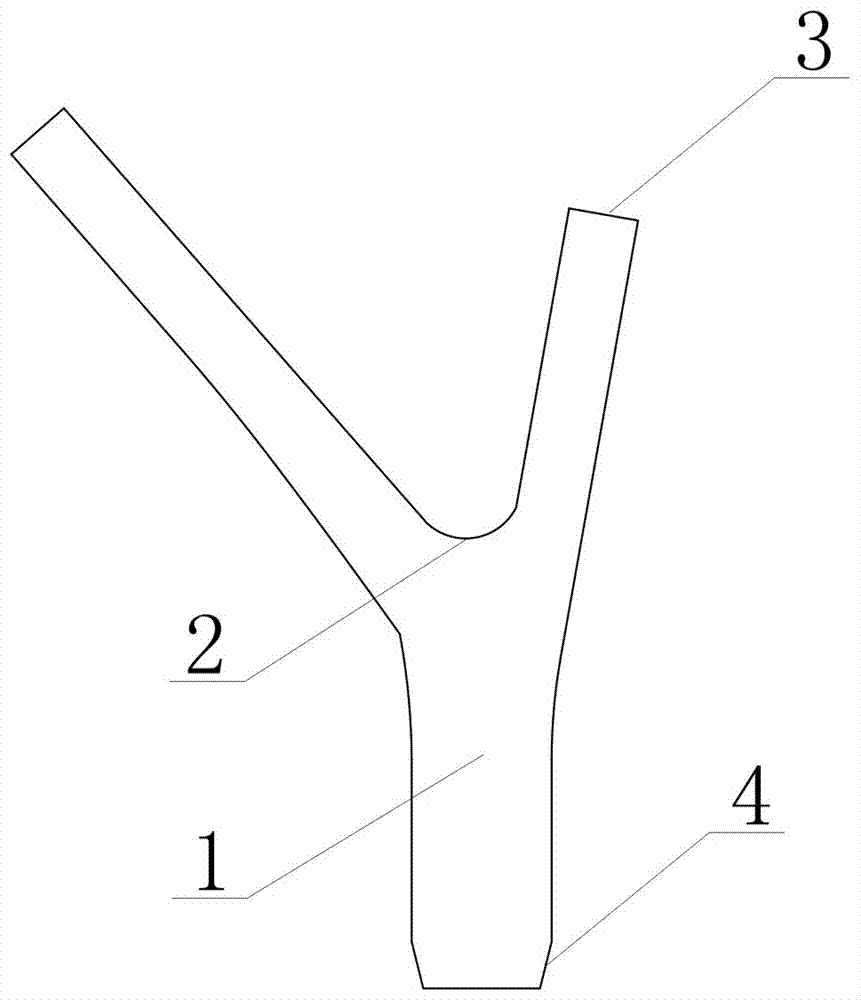

[0019] See attached Figure 5 ~ attached Figure 6 , the specific application of the present invention in the one-turn-two steel column: the lower side of the member is a small-section "ten"-shaped box-shaped steel column 9, and the upper side is a "Y"-shaped node member 10 with one turn-two. The parts are connected by forged steel node members 1.

[0020] See attached Figure 7 , the forged steel node member 1 is placed on the side wing plate 11 of the “Y” shaped node member 10, the lower connection end of the forged steel node member 1 is docked with the lower adapter plate 8, and the upper connection end is respectively connected with the left upper adapter plate 5 It is docked with the upper right adapter plate 6, and the butt joint adopts gas metal shielded welding, and the corresponding web is assembled and welded. The welding material is ER 50-G, which is equivalent to the base metal, and the diameter is 1.2mm. The gas is CO 2 , When welding forged steel parts, it m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com