Mechanical arm modular joint with redundant degree of freedom

A technology of modular joints and degrees of freedom, used in manipulators, manufacturing tools, joints, etc., can solve the problems of low joint integration, low load-to-weight ratio, and large volume, and achieve small size, low weight, and high load-to-weight ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

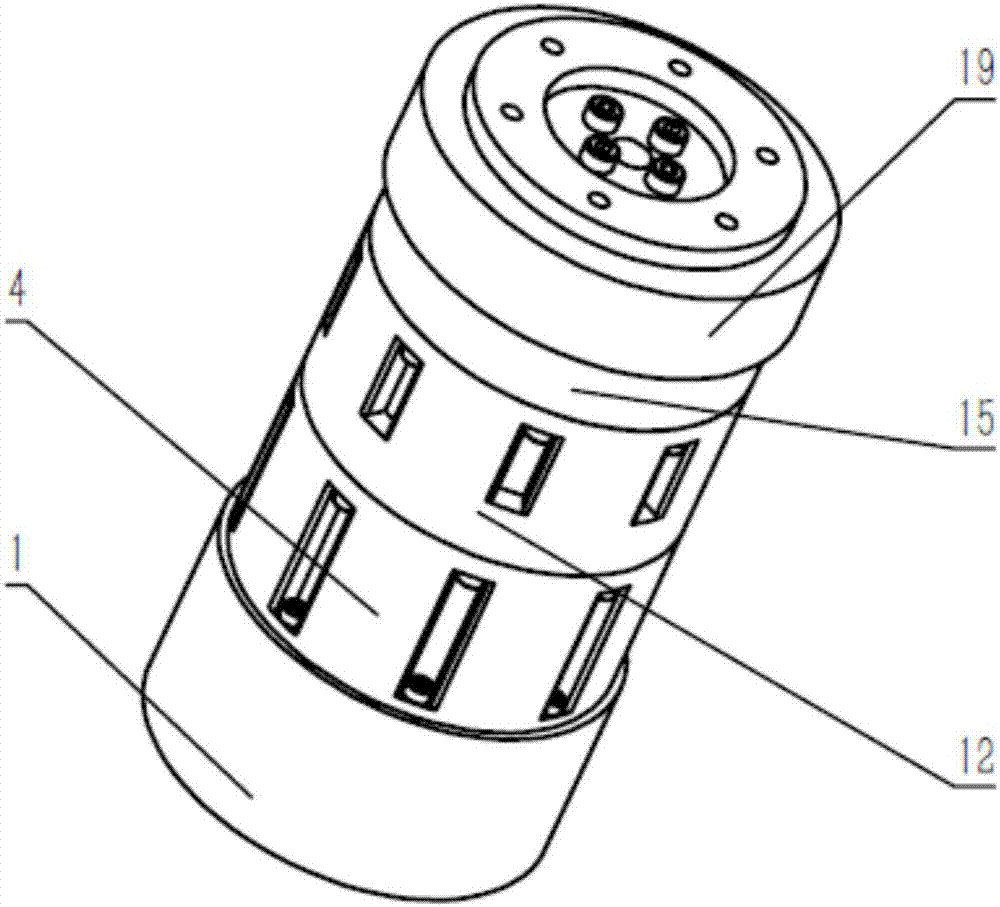

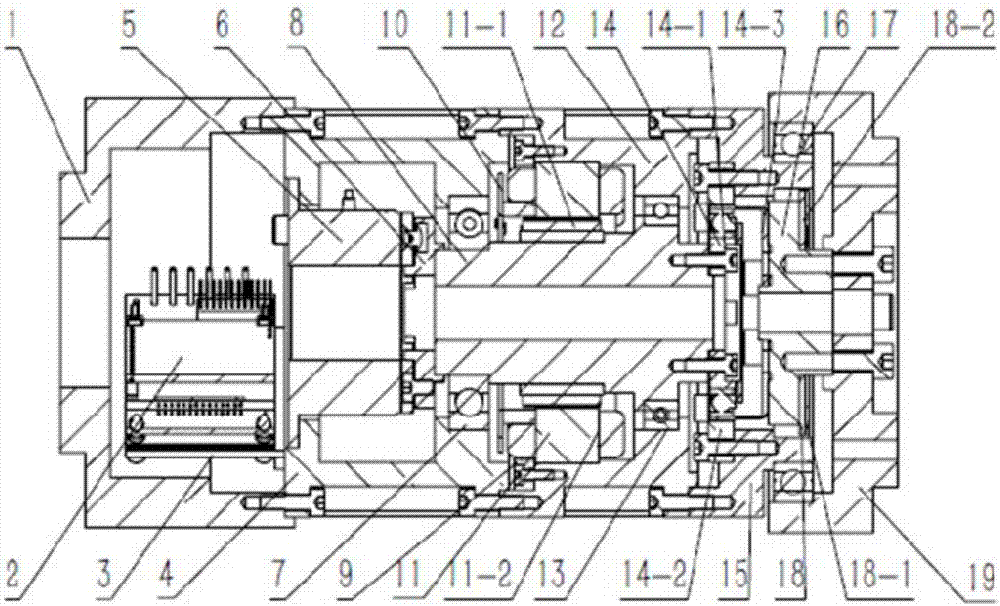

[0029] refer to Figure 1-Figure 5 , this embodiment provides a modular joint of a redundant degree of freedom manipulator, especially a lightweight redundant degree of freedom manipulator modular joint with a hollow structure, which includes a joint fixing part, a power assembly and an electrical part composition;

[0030] The joint fixing part includes a joint fixing end cover 1 , a driver bracket 3 , a brake fixing housing 4 , a motor fixing housing 12 and a harmonic reducer fixing housing 15 .

[0031] The joint fixing end cover 1 is fixed on the left end of the brake fixing housing 4 to close the left end of the brake fixing housing 4, and in this embodiment, the left end of the brake fixing housing 4 is the redundant degree of freedom The power input end of the modular joint of the mechanical arm; the right end of the fixed brake housing 4 is fixed to the left end of the fixed motor housing 12 , and the fixed housing 15 of the harmonic reducer is fixed to the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com