A vibrating wire type miniature strain gauge

A strain gauge and vibrating wire technology, which is applied in the field of geotechnical and engineering structure safety monitoring, can solve the problems of low measurement accuracy and large shape and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings.

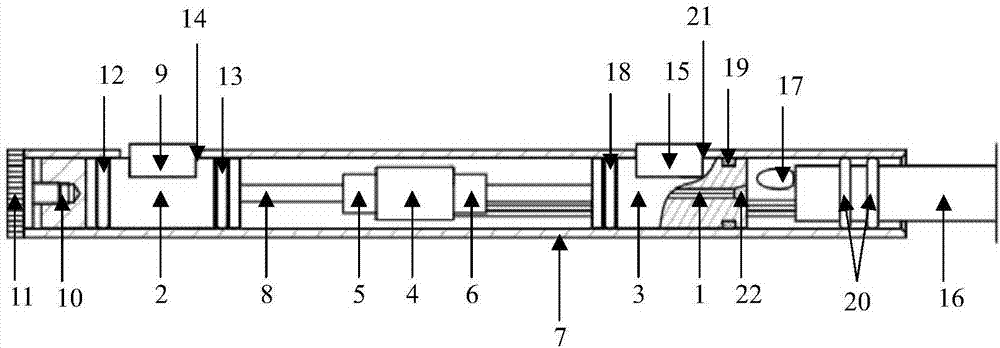

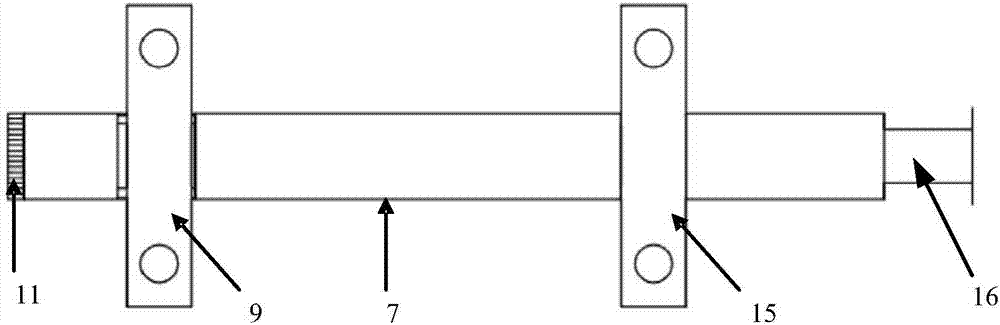

[0026] The present invention relates to a small vibrating wire strain gauge, which adopts a centralized structure design and is used to measure the strain in steel structures and structures with small spacing. The preferred structure is as follows figure 1As shown, it includes steel string 1, first end block 2, second end block 3, coil 4, first magnet 5, second magnet 6 and protective outer cylinder 7, steel string 1, coil 4, first magnet 5 and The second magnets 6 are all arranged in the protective outer cylinder 7, and the first end block 2 and the second end 3 are respectively arranged inside the two ends of the protective outer cylinder 7. The above-mentioned structure can avoid the steel string 1, the first end block 2 , the second end block 3 , the coil 4 , the first magnet 5 and the second magnet 6 are in direct contact with the measuring object, reducing the wear of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com