A kind of anti-floating and anti-stretching polyethylene winding structure wall pipe and its construction method

A technology of structural wall pipe and construction method, applied in the direction of pipe, rigid pipe, pipe connection arrangement, etc., can solve the problems of pulling, increase the difficulty of construction, leakage of pipe connection, etc., to prevent shaking, prevent fracture, and achieve high connection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

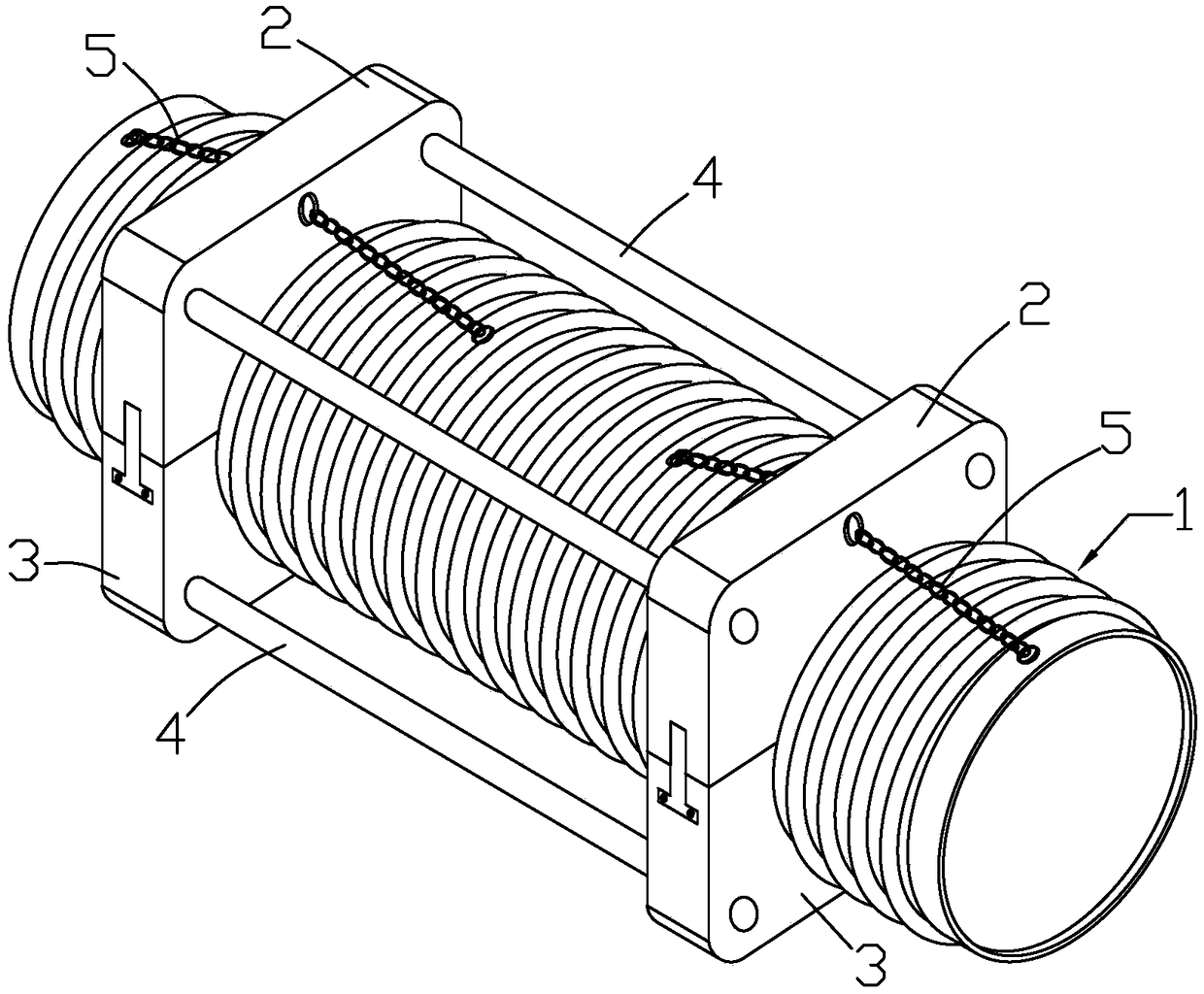

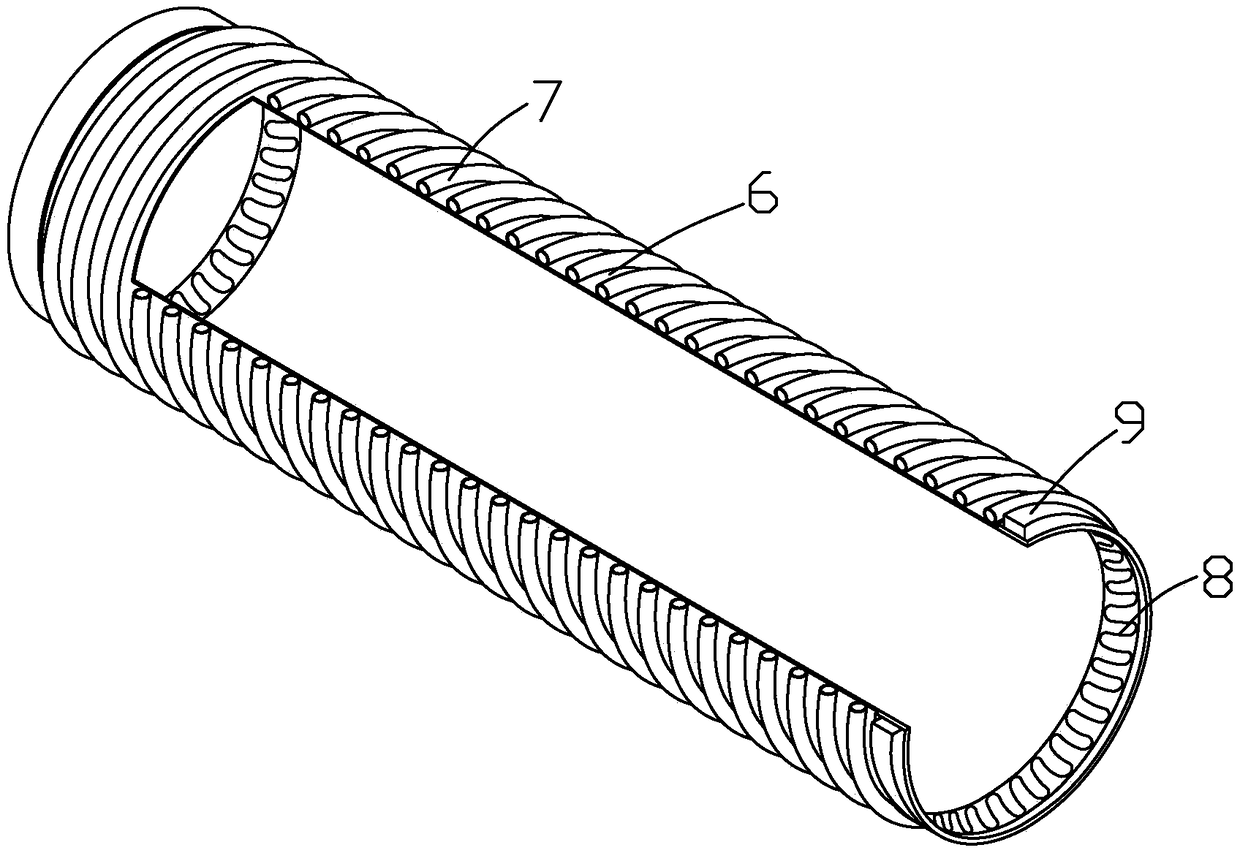

[0043] Such as Figure 1 to Figure 4As shown, it is an anti-floating and tensile-resistant polyethylene winding structure wall pipe of the present invention, comprising a pipe body 1, the pipe body 1 includes a pipe wall 6 and a threaded pipe 7, and the threaded pipe 7 is evenly wound around the wall of the pipe wall 6 On the outer surface, the threaded pipe 7 is provided with reinforcing ribs 15. The reinforcing ribs 15 can improve the compression resistance of the threaded pipe 7, and at the same time make the wall pipe have better tensile damage resistance. There are welding wires 8, and the welding wires 8 are distributed in an S shape. The S shape design improves the sealing degree of the welding between the pipe walls 6, and improves the strength and stability of the connection.

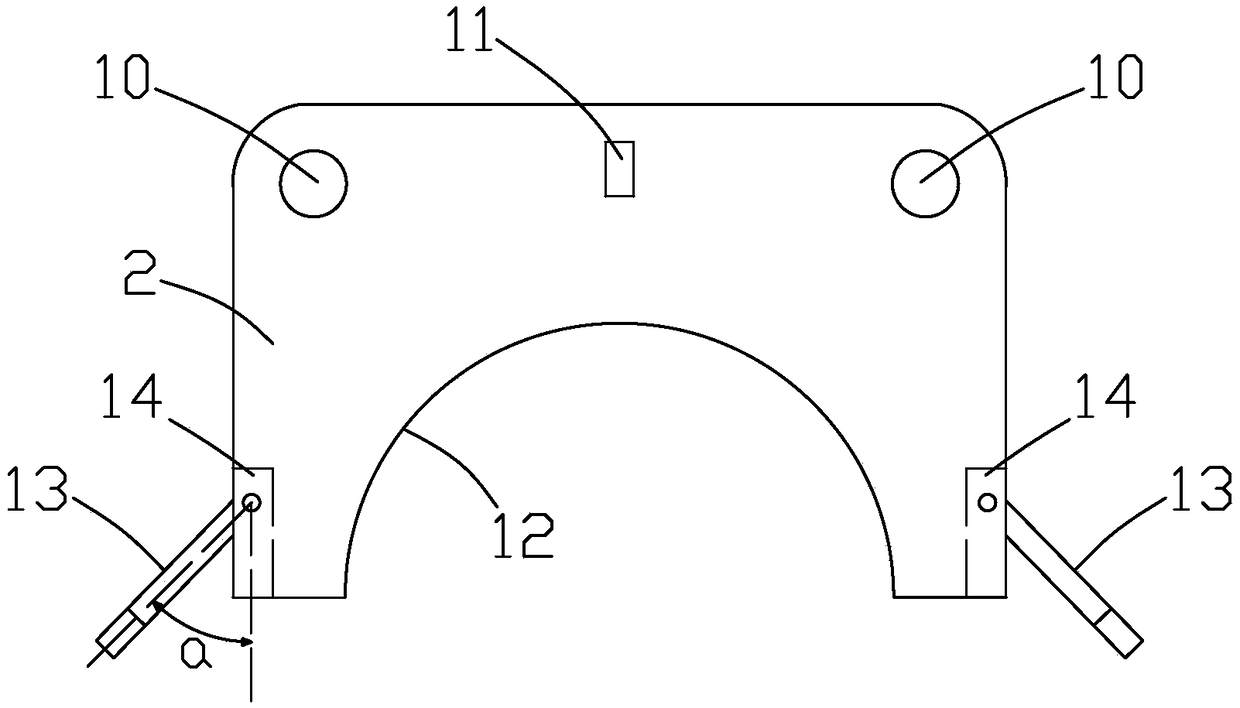

[0044] It also includes a clamping device, and the two adjacent clamping devices on the left and right are fixedly connected by a connecting rod 4. The clamping device includes an upper clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com