dual clutch

A dual clutch, clutch technology, applied in clutches, fluid-driven clutches, mechanically-driven clutches, etc., can solve the problem of increasing the moment of inertia, and achieve the effect of reducing the tendency of unbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

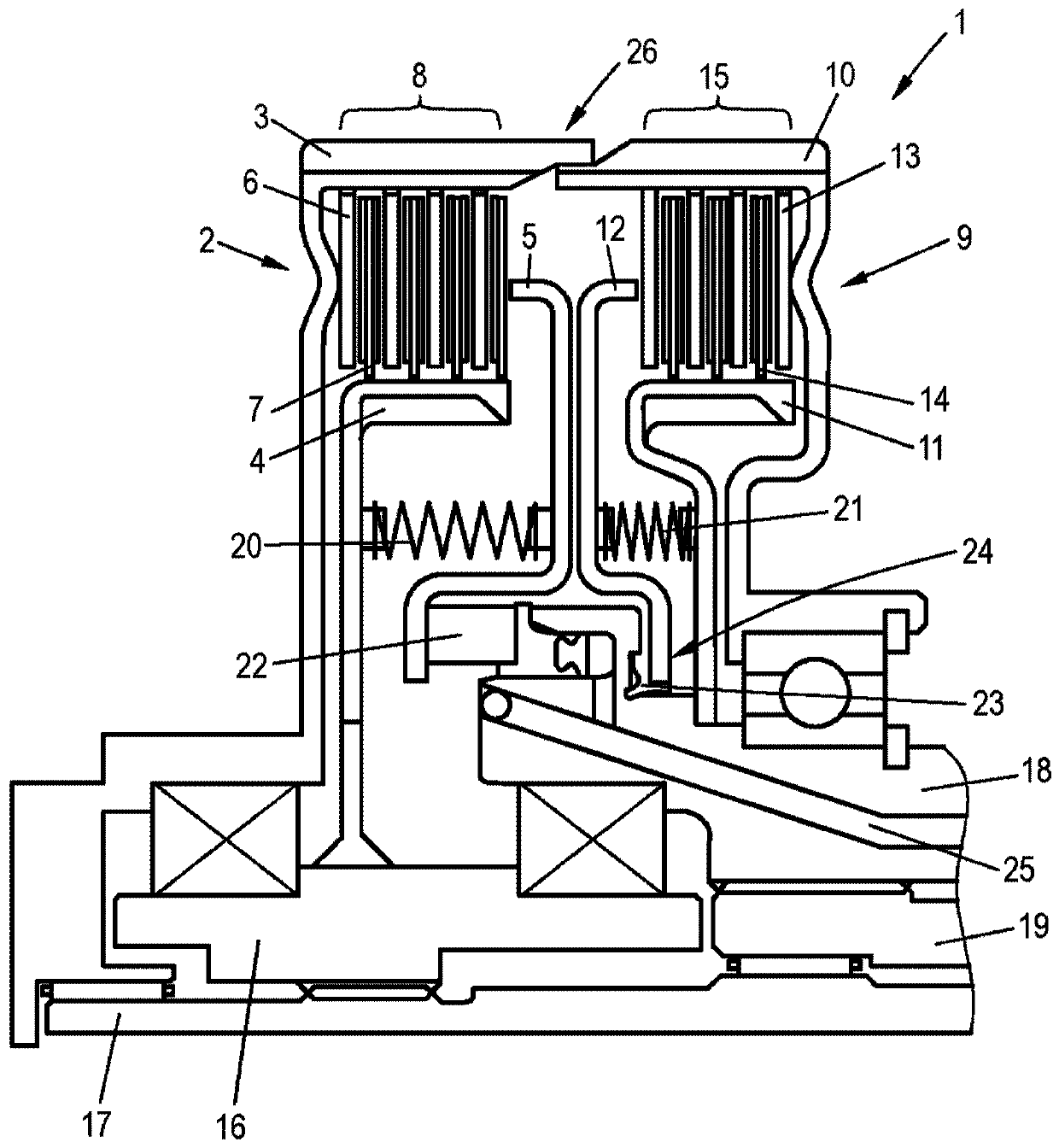

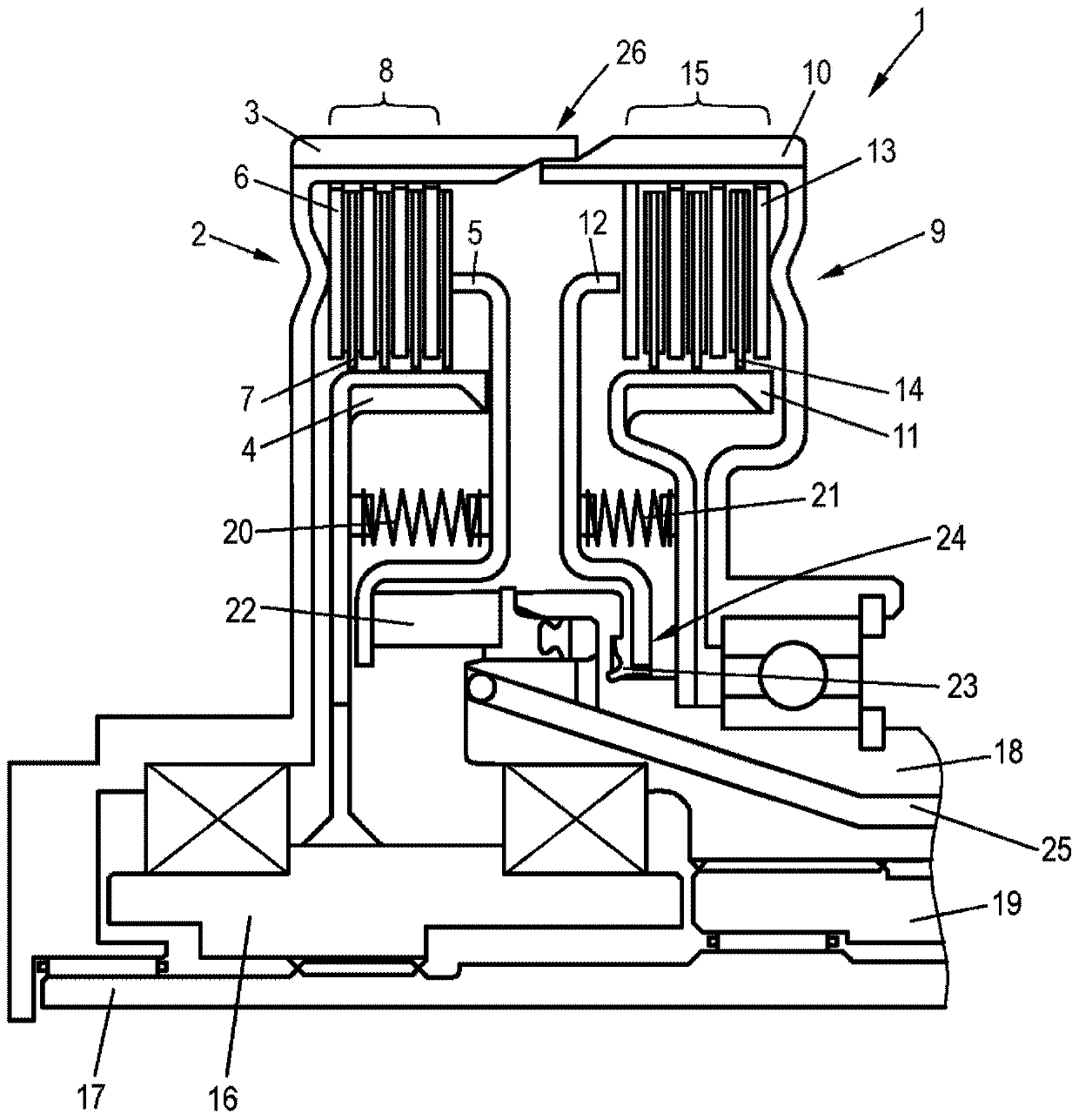

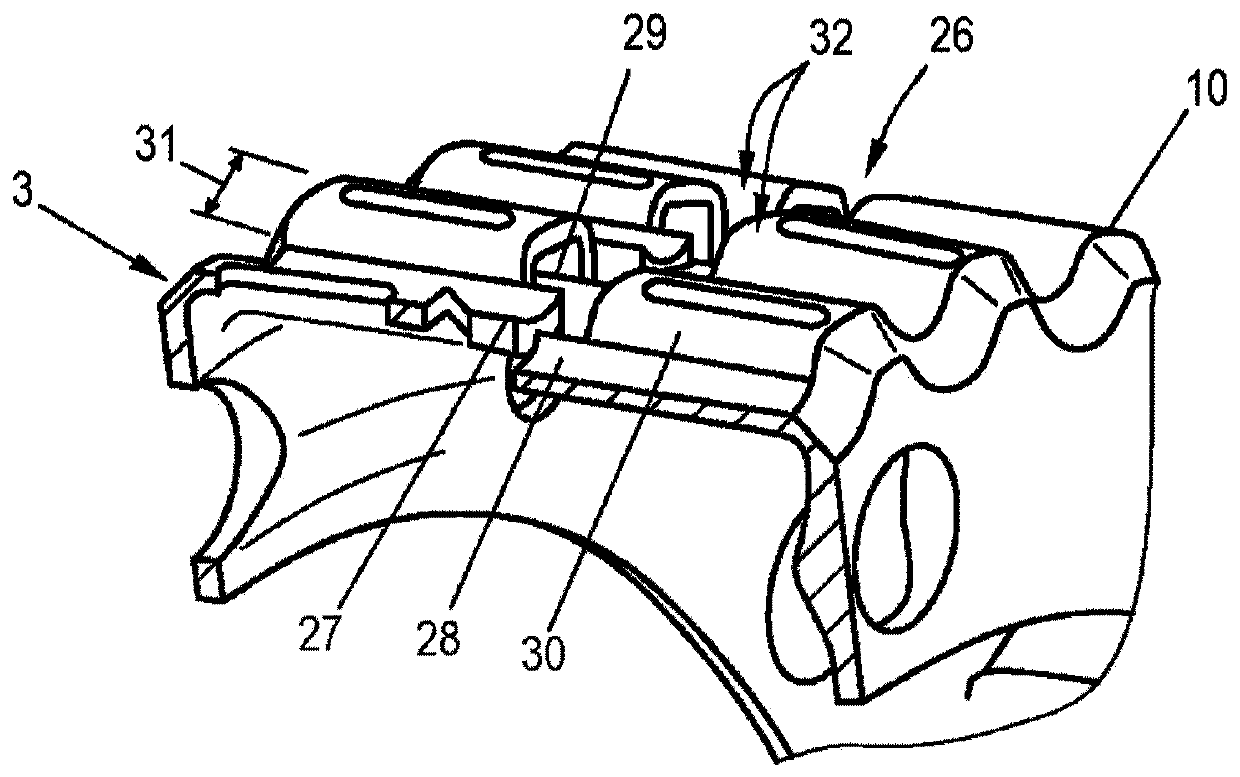

[0028] figure 1 The double clutch 1 is shown, which comprises a first partial clutch 2 and a second partial clutch 9 , the first partial clutch 2 has a first outer disk carrier 3 , a first inner disk carrier 4 and can be operated by means of a first actuating part 5 Operationally, the first disk pack 8 consisting of the first outer disk 6 assigned to the first outer disk carrier 3 and the first inner disk 7 assigned to the first inner disk carrier 4 , the second sub-branch The clutch 9 has a second outer disk carrier 10 , a second inner disk carrier 11 and a second outer disk 13 assigned to the second outer disk carrier 10 and a second outer disk 13 assigned to the first The second friction plate group 15 constituted by the second inner friction plates 14 of the two inner friction plate supports 11 .

[0029] The first partial clutch 2 and the second partial clutch 9 are clearly adjacent to each other in the axial direction. The first inner lining carrier 4 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com