A bullet-bore vegetable conveying device for a vegetable cutter

The technology of a conveying device and a vegetable cutting machine, which is applied in the direction of metal processing, can solve the problems of high labor intensity, heavy vegetable cutting tasks, and low production efficiency of the staff, and achieves improved vegetable cutting efficiency, convenient use and maintenance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

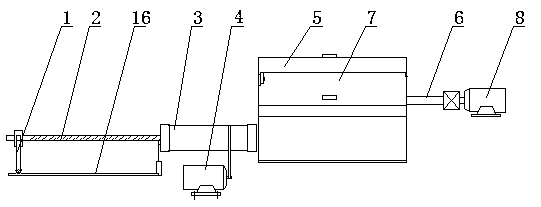

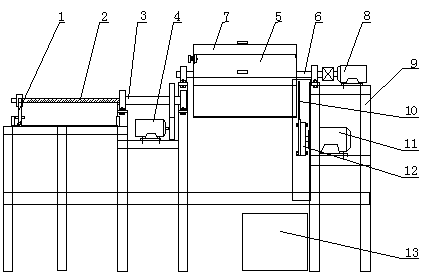

[0019] The bullet-bore vegetable conveying device for a vegetable cutter is composed of a feed screw 2, a screw sleeve shaft 3, a mounting shaft 6 and a plurality of vegetable conveying cylinders 5; the mounting shaft 6 is fixedly equipped with a plurality of vegetable conveying cylinders 5. The number of vegetable delivery tubes 5 is 3; each vegetable delivery tube 5 is provided with a delivery tube door 7 through a hinge, so that the vegetables to be cut are placed in the vegetable delivery tube 5 . Vegetable conveying cylinder 5 is arranged on the circumference of mounting shaft 6 in a character shape. One end of the mounting shaft 6 is provided with a stepping motor 8, and the stepping motor 8 is connected with the mounting shaft 6 through a coupling.

[0020] One end of the vegetable conveying cylinder 5 is slidably installed with a bracket 1 through a slide rail 16, and a screw sleeve shaft 3 is installed between the slide rail 16 and the vegetable conveying cylinder 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com