Magnetic composite adsorbent and preparation method thereof

A composite adsorption and magnetic technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as difficulty in recycling, loss of powder materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

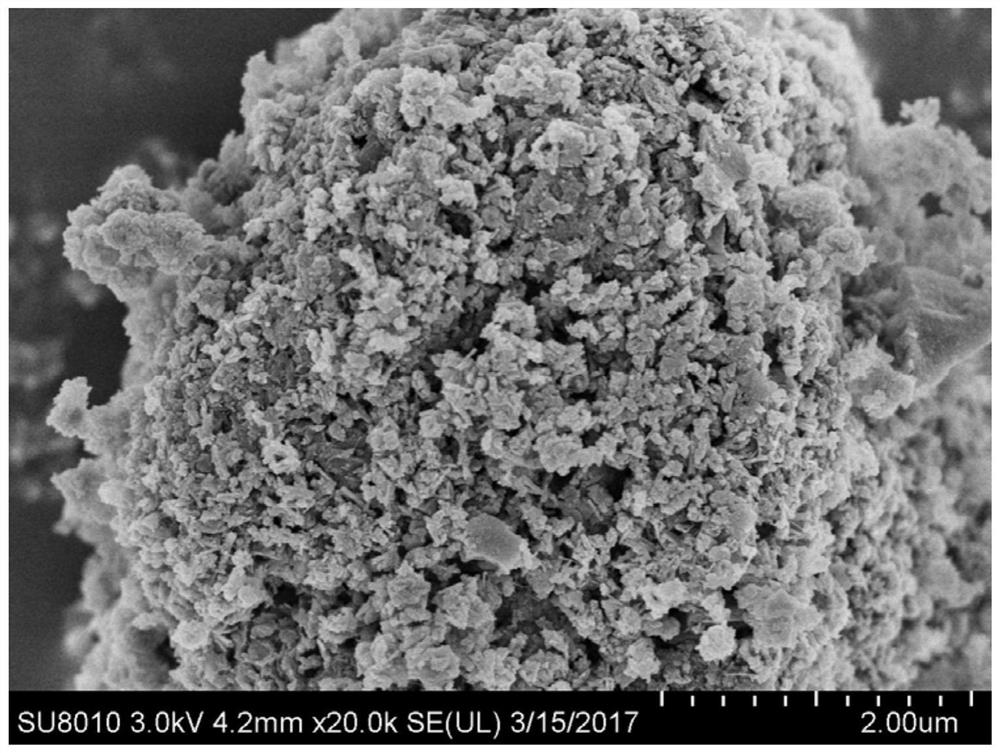

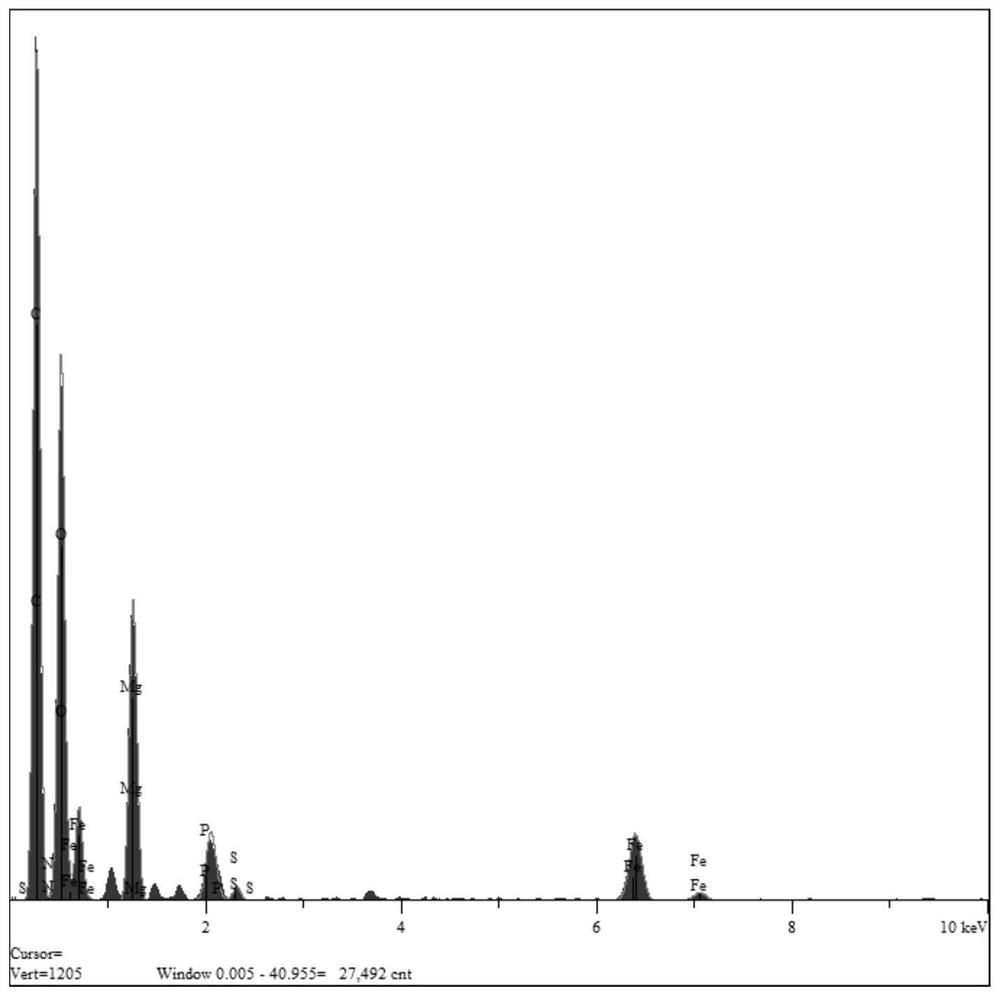

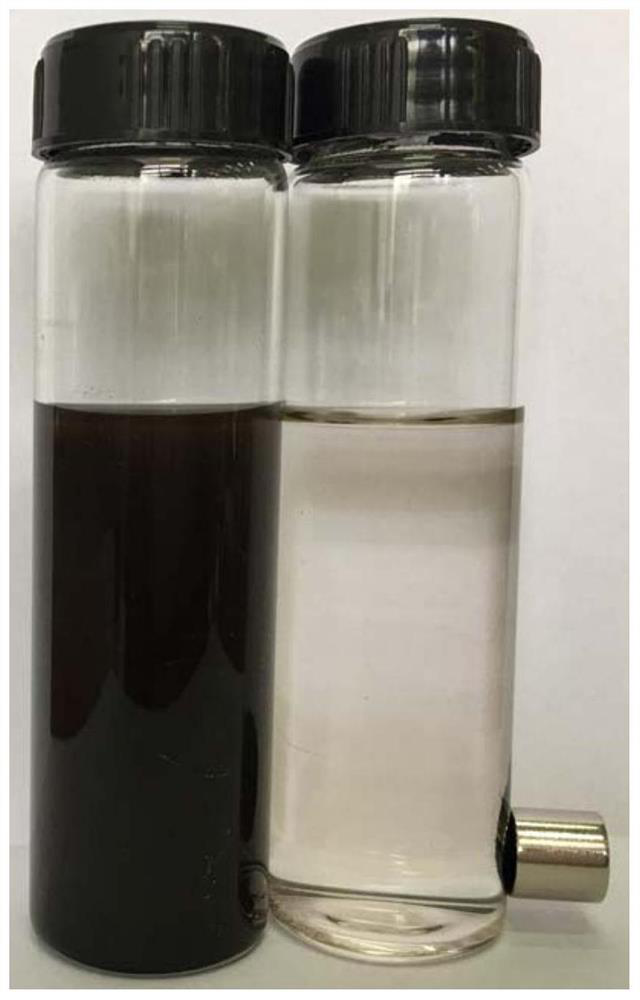

[0033] A kind of magnetic composite adsorbent of the present invention, this magnetic composite adsorbent comprises porous magnesium hydroxide, Fe 3 o 4 Nanoparticles and biochar made from betel nut slag, the magnetic composite adsorbent is supported by porous magnesium hydroxide loaded with biochar and Fe 3 o 4 Nanoparticles.

[0034] A kind of preparation method of the magnetic composite adsorbent of above-mentioned present embodiment, comprises the following steps:

[0035] (1) Preparation of biochar: dry the collected betel nut slag and crush it with a pulverizer for 30 seconds; place the pulverized betel nut slag in a 2 The pyrolysis is carried out under protection, the heating rate of the pyrolysis is 15°C / min, the final temperature is 450°C, and the maintenance time is 1h. Grinding after cooling to obtain biochar. After testing, the specific surface area of biochar is 6.3682±0.1298m 2 / g.

[0036](2) Preparation of magnesium hydroxide carrier: in the microemuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com