Solder paste temperature returning apparatus used for lamp bar production

A technology for solder paste and light strips, applied in mixers, mixers with rotating stirring devices, shaking/oscillating/vibrating mixers, etc., can solve problems such as unsatisfactory return temperature, and achieve the effect of simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

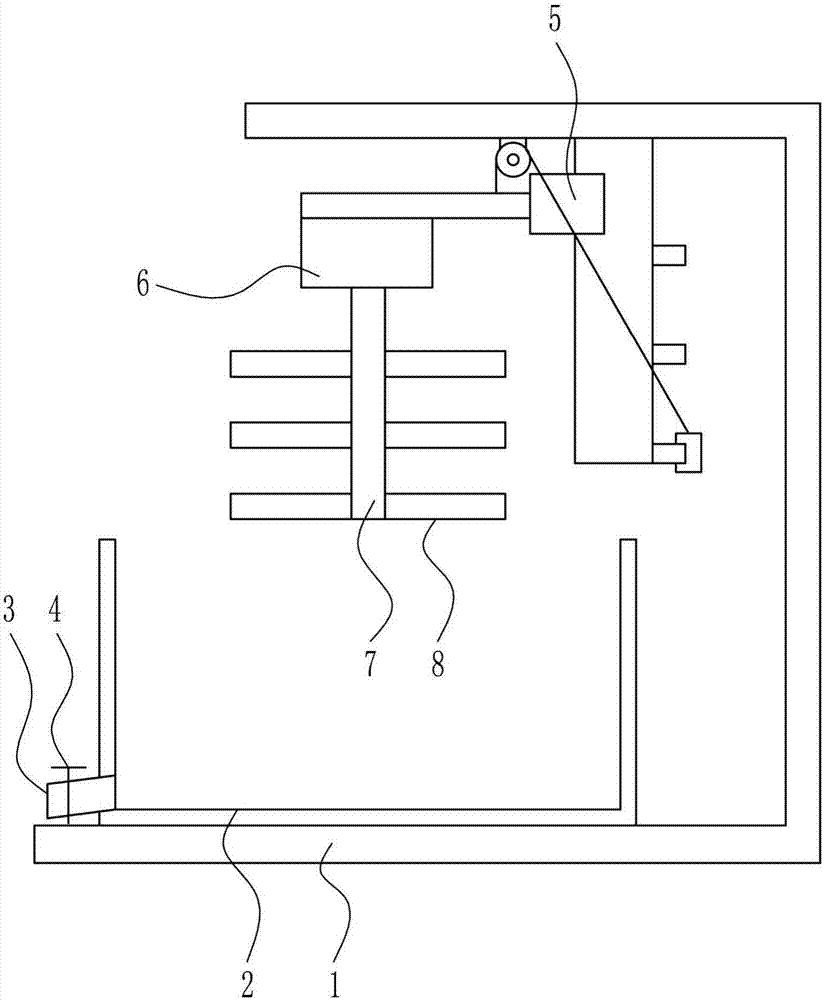

[0027] A kind of solder paste reheating equipment for light bar production, such as Figure 1-4 As shown, it includes a mounting frame 1, a frame body 2, a discharge pipe 3, a valve 4, a height adjustment device 5, a first motor 6, a stirring shaft 7 and a stirring rod 8. The inner bottom of the mounting frame 1 is provided with a frame body 2. The lower part of the left wall of the frame 2 is provided with a discharge pipe 3, the discharge pipe 3 is provided with a valve 4, the top of the mounting frame 1 is provided with a height adjustment device 5, the height adjustment device 5 is provided with a first motor 6, a first motor 6 is provided with a stirring shaft 7 in the center of the bottom, a stirring rod 8 is arranged at the lower part of the stirring shaft 7, and the stirring rod 8 is above the frame body 2.

Embodiment 2

[0029] A kind of solder paste reheating equipment for light bar production, such as Figure 1-4 As shown, it includes a mounting frame 1, a frame body 2, a discharge pipe 3, a valve 4, a height adjustment device 5, a first motor 6, a stirring shaft 7 and a stirring rod 8. The inner bottom of the mounting frame 1 is provided with a frame body 2. The lower part of the left wall of the frame 2 is provided with a discharge pipe 3, the discharge pipe 3 is provided with a valve 4, the top of the mounting frame 1 is provided with a height adjustment device 5, the height adjustment device 5 is provided with a first motor 6, a first motor 6 is provided with a stirring shaft 7 in the center of the bottom, a stirring rod 8 is arranged at the lower part of the stirring shaft 7, and the stirring rod 8 is above the frame body 2.

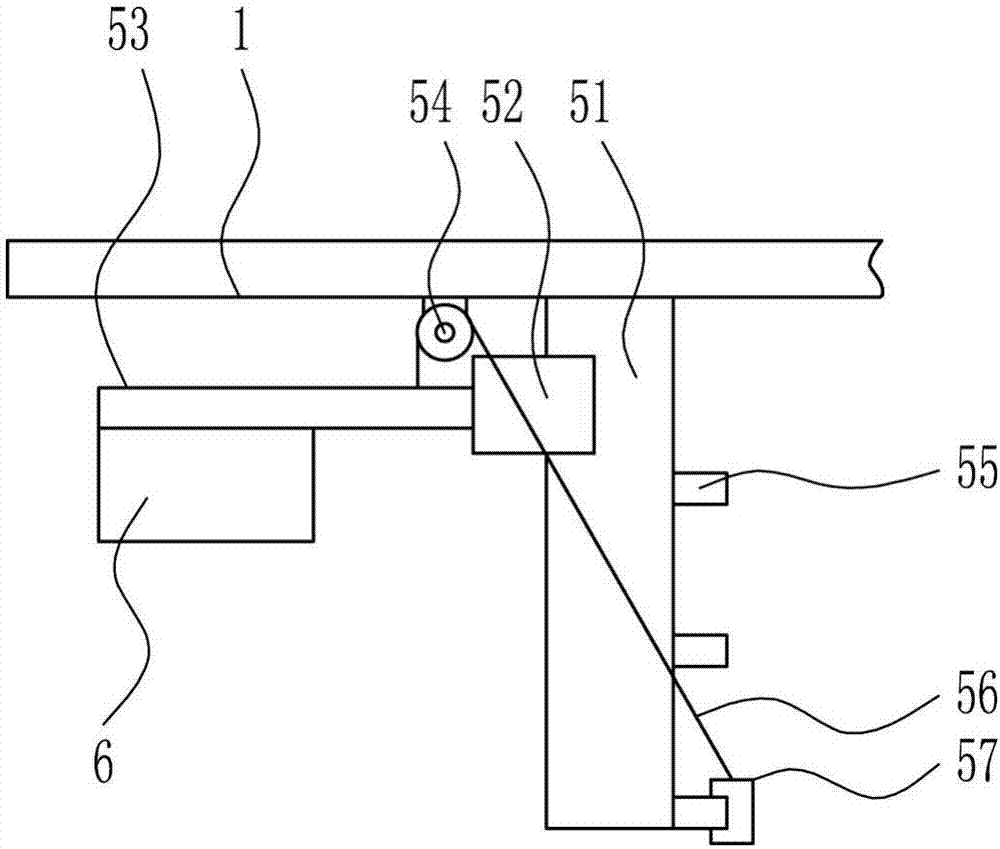

[0030] The height adjustment device 5 includes a first sliding rail 51, a first sliding block 52, a mounting plate 53, a fixed pulley 54, a convex column 55, a rope ...

Embodiment 3

[0032] A kind of solder paste reheating equipment for light bar production, such as Figure 1-4 As shown, it includes a mounting frame 1, a frame body 2, a discharge pipe 3, a valve 4, a height adjustment device 5, a first motor 6, a stirring shaft 7 and a stirring rod 8. The inner bottom of the mounting frame 1 is provided with a frame body 2. The lower part of the left wall of the frame 2 is provided with a discharge pipe 3, the discharge pipe 3 is provided with a valve 4, the top of the mounting frame 1 is provided with a height adjustment device 5, the height adjustment device 5 is provided with a first motor 6, a first motor 6 is provided with a stirring shaft 7 in the center of the bottom, a stirring rod 8 is arranged at the lower part of the stirring shaft 7, and the stirring rod 8 is above the frame body 2.

[0033] The height adjustment device 5 includes a first sliding rail 51, a first sliding block 52, a mounting plate 53, a fixed pulley 54, a convex column 55, a rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com