A heavy metal stabilizer with water-reducing and flocculating properties and preparation method thereof

A heavy metal stabilizer and flocculation technology, applied in the field of environmental engineering, can solve the problems of deviation of treatment effect and large dosage, and achieve the effect of reducing the cost of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

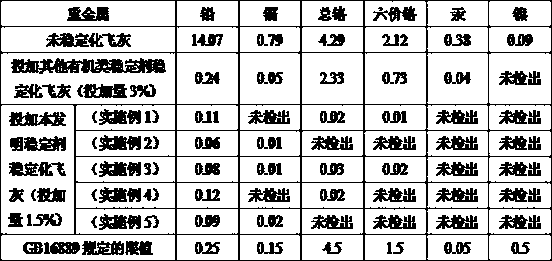

Examples

Embodiment 1

[0020] Stir at 45°C at a speed of 130r / min to dissolve the following components: 25% dithiocarbamate, 15% dithioaminoacetate, 5% ethyl xanthate, allyl alcohol polyoxyethylene Ether 1%, isobutanol polyoxyethylene ether 1.5%, hydroxyethyl acrylate 0.5%, polyacrylamide 0.2%, sodium nitril triacetate 0.15%, sucrose 1.5%, sodium polyacrylate 0.05%, the rest of water, stirring The time is 1 hour, and the heavy metal stabilizer with both water-reducing and flocculating properties is obtained.

Embodiment 2

[0022] Stir at 55°C at a speed of 145r / min to dissolve the following components: 35% dithiocarbamate, 10% dithioaminoacetate, 5% ethyl xanthate, allyl alcohol polyoxyethylene Ether 0.5%, isoamyl alcohol polyoxyethylene ether 0.5%, isobutanol polyoxyethylene ether 0.5%, hydroxyethyl acrylate 0.5%, polyacrylamide 0.1%, sodium nitrilotriacetate 0.05%, sucrose 2.5%, polyacrylic acid Sodium 0.1%, the balance of water, stirring time is 2h, that is, a heavy metal stabilizer with both water reducing and flocculating properties can be obtained.

Embodiment 3

[0024] Stir at 40°C at a speed of 120r / min to dissolve the following components: 28% dithiocarbamate, 5% dithioaminoacetate, 6% ethyl xanthate, isoamyl alcohol polyoxyethylene 0.7% ether, 0.8% isobutanol polyoxyethylene ether, 0.8% hydroxyethyl acrylate, 0.14% polyacrylamide, 0.08% sodium nitril triacetate, 1.7% sucrose, 0.06% sodium polyacrylate, the rest of water, stirring The time is 1.4 hours, and the heavy metal stabilizer with both water-reducing and flocculating properties is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com