Grain drying and dedusting device and method

A technology for dust removal equipment and grain drying, applied in chemical instruments and methods, preservation of seeds by drying, solid separation, etc., can solve the problem of limited dust removal effect, and achieve the effects of saving motor costs, suppressing equipment damage, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

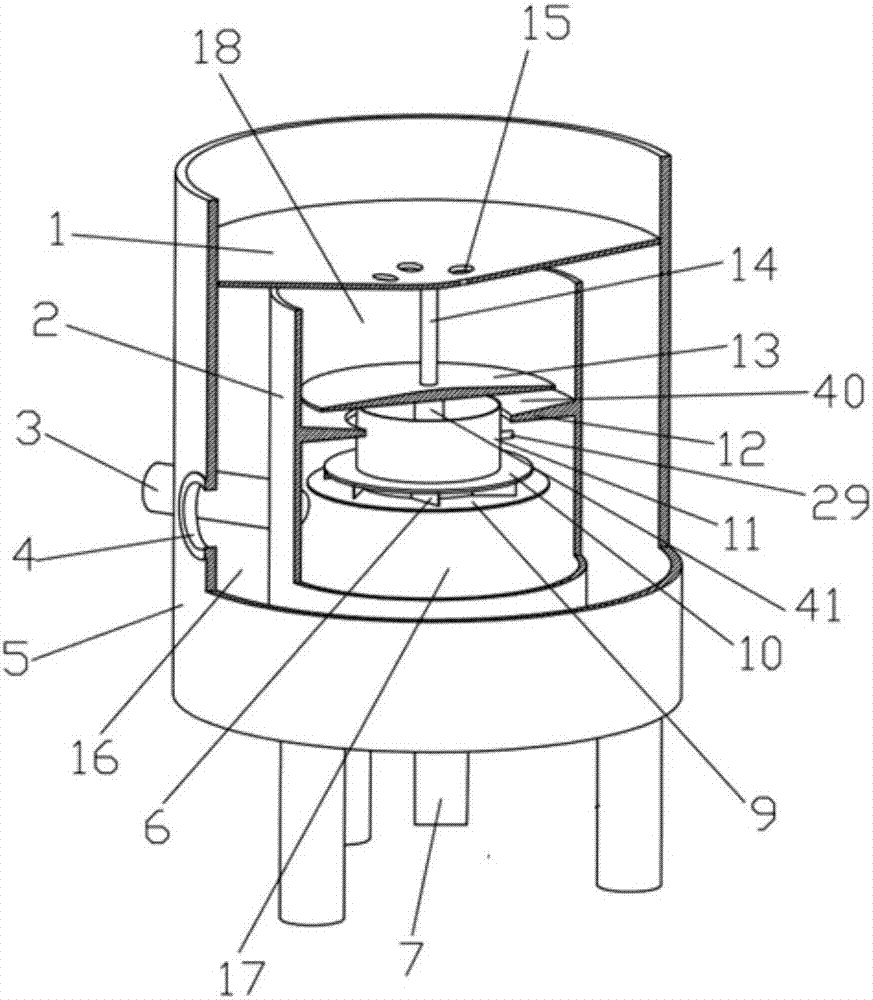

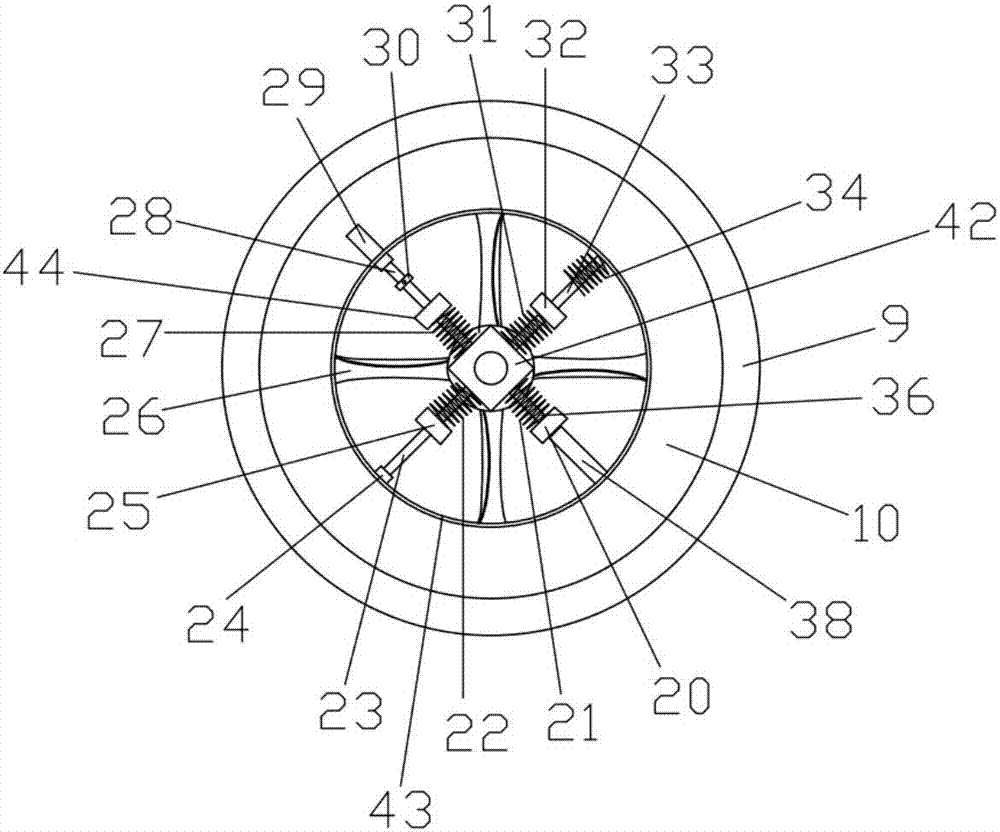

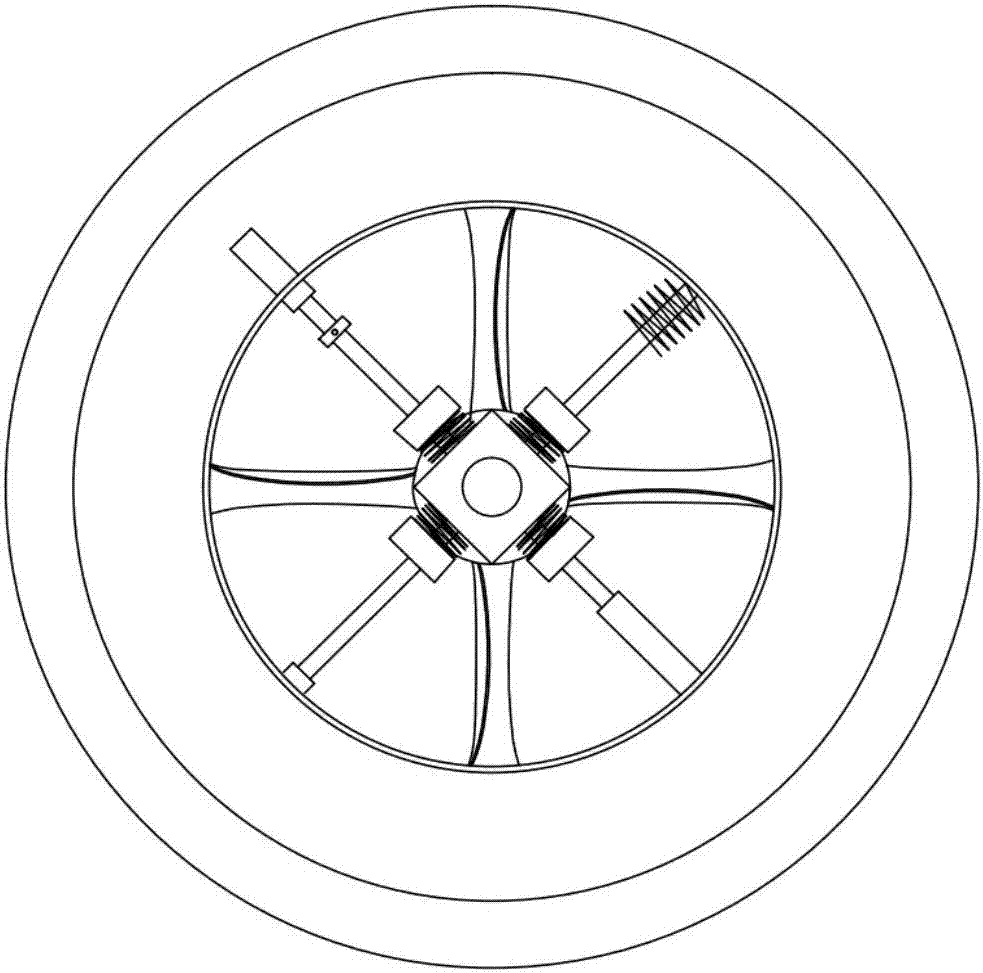

[0026] as attached figure 1Shown, a kind of grain dry dedusting equipment comprises machine outer container 5, the first blanking plate 1, dust removal reaction container 2, the second blanking plate 13, the 3rd blanking plate 12 and fan vibration unit 11; Said machine The outer container 5 is a cylindrical container structure with an open top; the first blanking plate 1 is a concave circular plate structure, and there are a number of leakage holes 15 evenly in the middle of the concave plate, and the first blanking plate 1 is horizontally arranged on the machine. The inner cavity of the outer container 5, the first blanking plate 1 divides the inner cavity of the outer container 5 of the machine into the upper cavity of the outer container of the machine and the lower cavity of the outer container of the machine, wherein the inner side wall of the lower cavity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com