Carrier grade LC optical fiber fast connector

A technology of connectors and optical fibers, which is applied in the field of carrier-grade LC type optical fiber fast connectors, can solve the problems of high construction costs and maintenance costs, and the inability to accurately measure the distance of optical fiber wiring, and achieve the effect of reducing construction costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

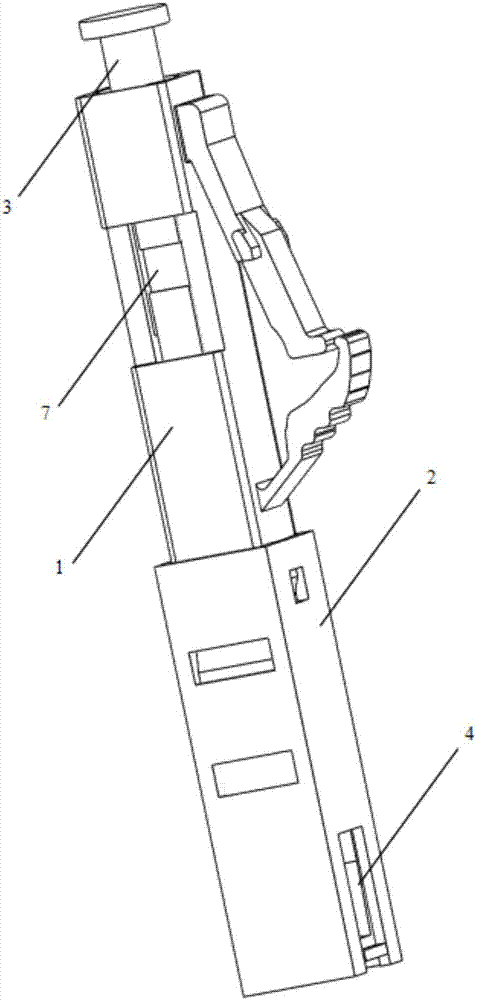

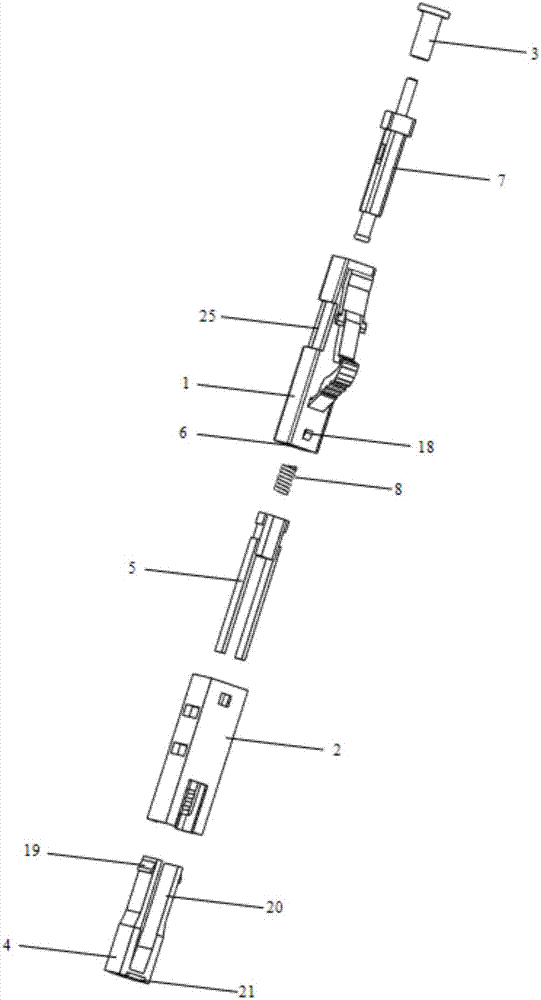

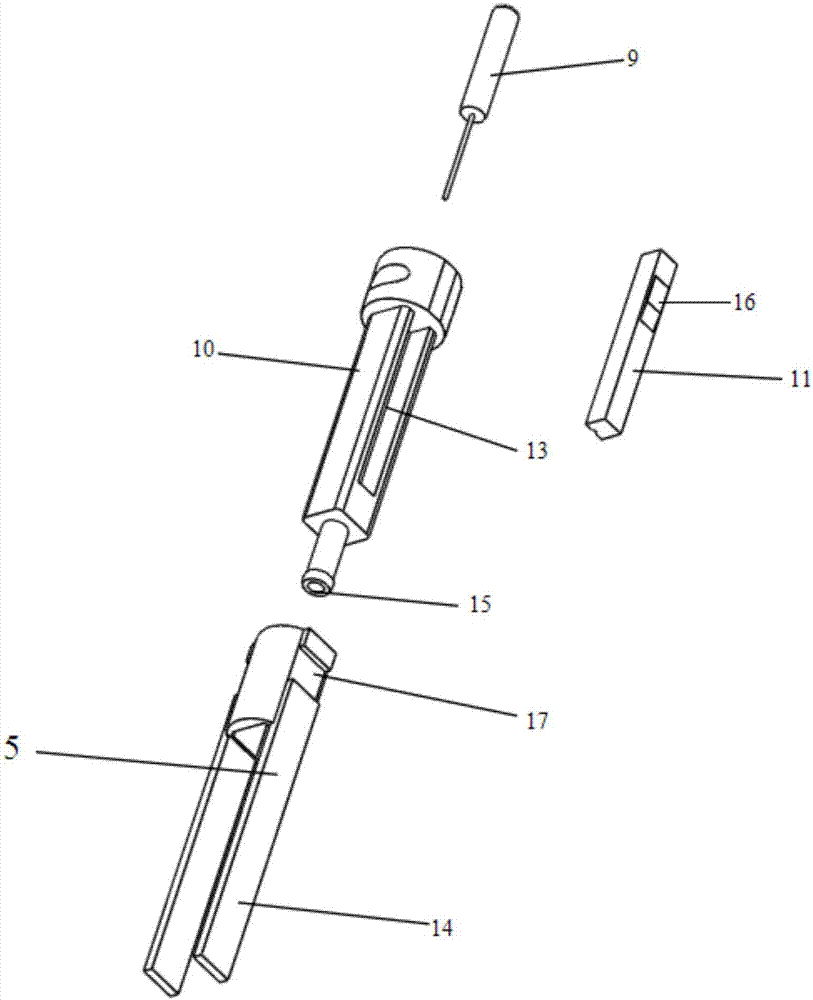

[0034] Reference Figure 1-5 As shown, this embodiment discloses a telecommunication-grade LC type optical fiber quick connector, which mainly includes: a front body 1, a rear body 2, a dust cap 3, a tail pressing block 4, a slider 5, and a V-groove device 7. Spring 8.

[0035] Wherein, the front body 1 is provided with a cavity for accommodating the passage of optical fibers, and the front body 1 is provided with a core guiding and positioning hole 6 which penetrates the inner cavity, and the above-mentioned core guiding and positioning hole 6 is arranged in On a free end of the front body 1, the core guide positioning hole 6 has a horn-shaped structure, and the horn-shaped structure facilitates the introduction of optical fibers. The front body 1 has a hollow structure, the V-groove assembly 7 is disposed in the front body 1, and the V-groove assembly 7 is a core guide positioning device.

[0036] In addition, a hand dial window 25 is also provided on the front body 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com