Rainfall test system

A rain test and rain technology, applied in the field of rain test system, can solve the problems of economic loss, inability to accurately detect the airtightness of the vehicle body, and customer insecurity, and achieve the effect of reducing adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

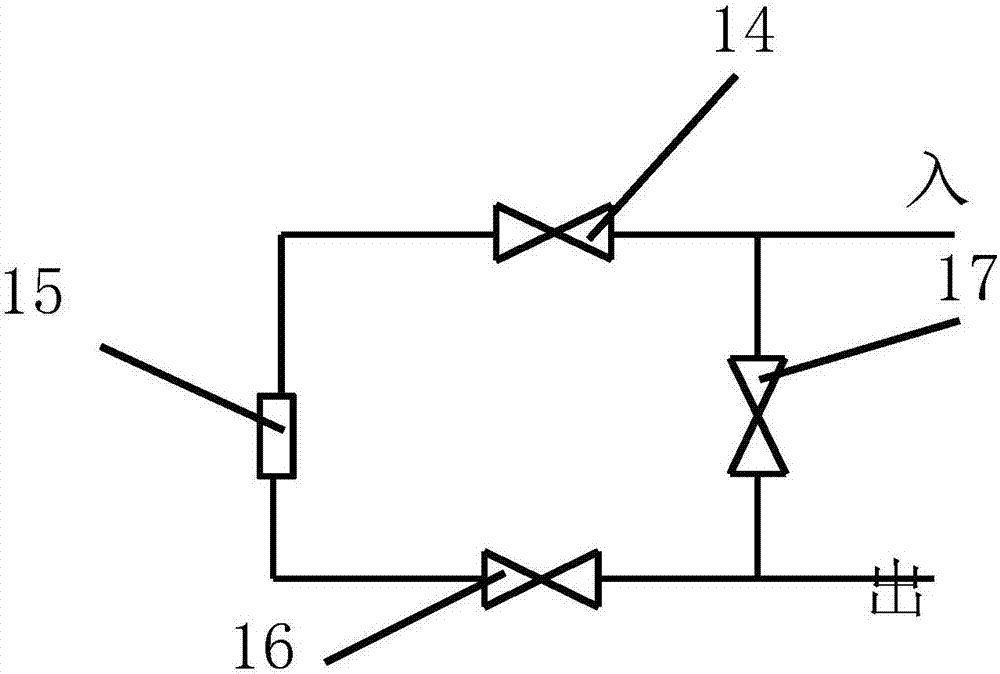

[0024] Such as figure 1 The shown rain test system includes a rain shower room 1 and a drying room 2 connected to the rain shower room 1. A drying system is provided in the drying room 2, and a spraying system is provided in the rain shower room 1. System 3 and the first camera monitoring system, the bottom of the rain shower room 1 is provided with a return pool, and also includes a sprinkler head installation plate 22, and the shower head installation plate 22 is installed in the rain shower room 1 through a linear drive mechanism 21, so The linear drive mechanism 21 can be realized in many ways, such as cylinder, screw module, scissor lift table, etc. When the cylinder is used, the cylinder can be fixed on the top surface of the rain shower room 1 through fasteners such as bolts. The piston rod of the air cylinder is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com