Body structure for double track vehicles

A body and vehicle technology, applied in substructure, vehicle components, vehicle design optimization, etc., can solve the problems of high risk of destroying rear axle modules and support parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

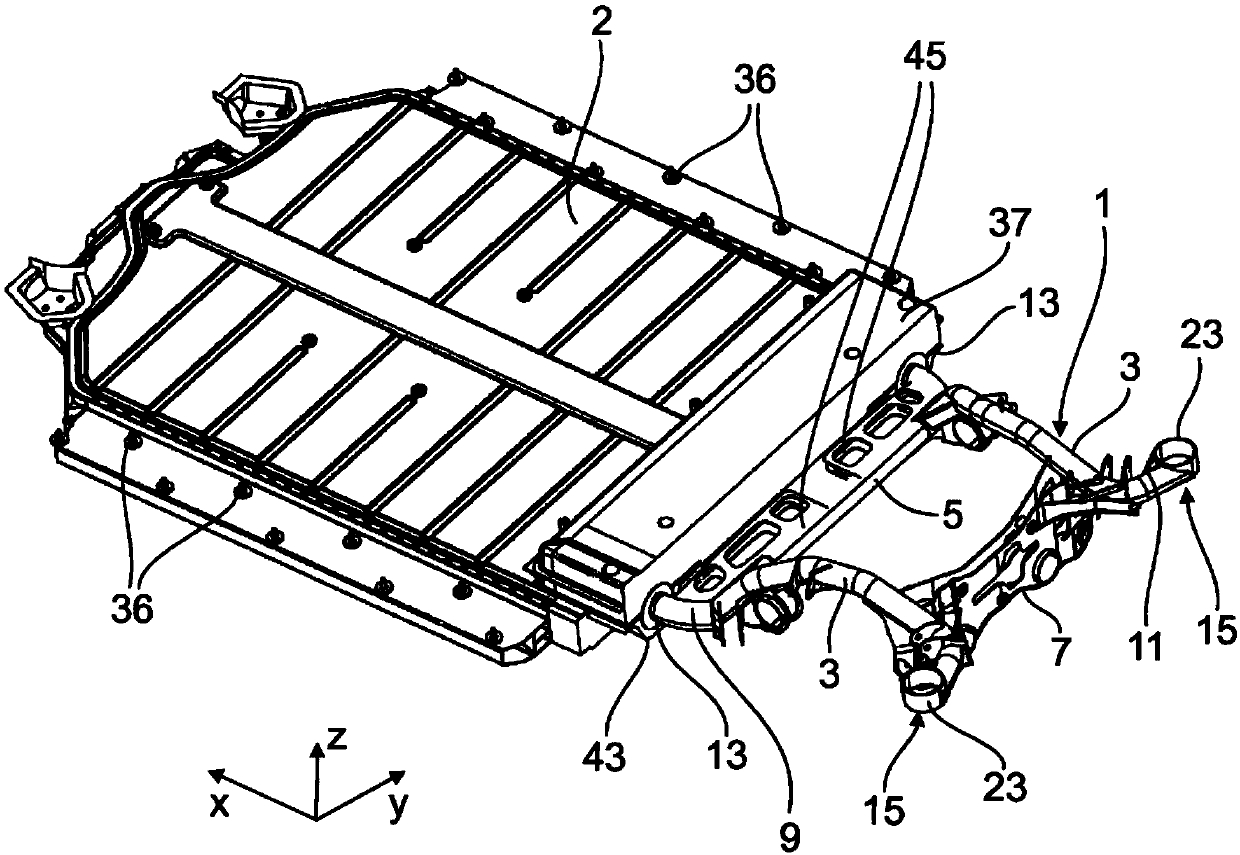

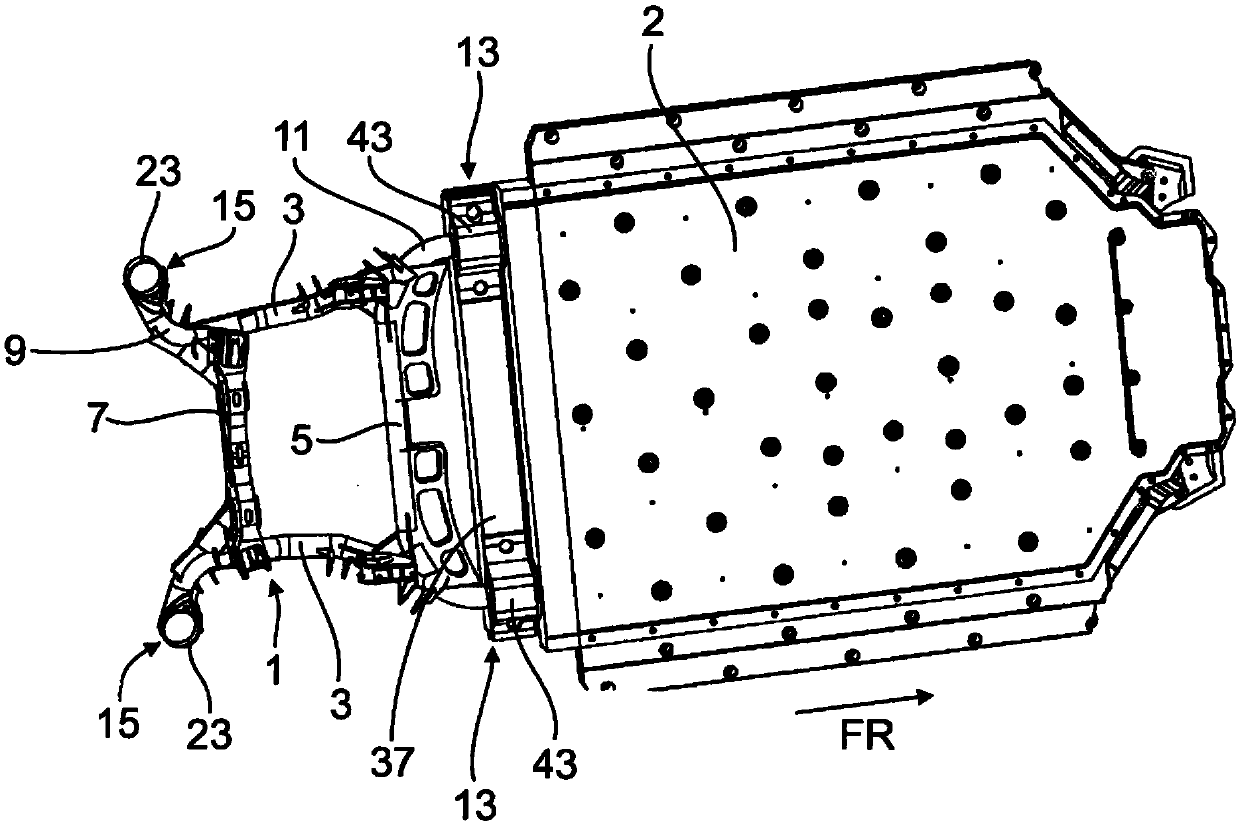

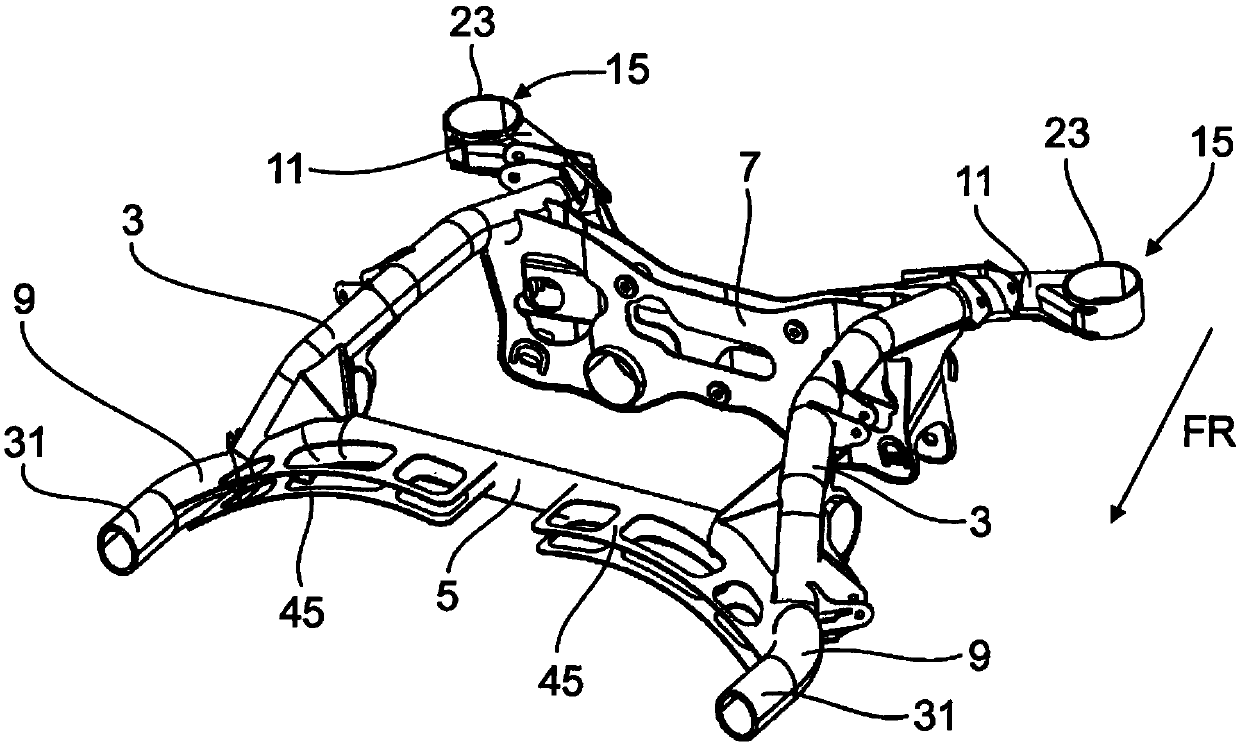

[0028] exist figure 1 shows in a perspective view the arrangement of a rear subframe 1 for the rear axle of the vehicle and a traction battery 2 at the front in the vehicle longitudinal direction x, which can be installed in an electrically driven motor vehicle. The subframe 1 is in figure 1 The center is configured as a rectangular closed structure and has subframe longitudinal supports 3 spaced apart from one another in the vehicle transverse direction y and has a front transverse support 5 and a rear transverse support 7 . The two transverse supports run in the transverse vehicle direction y and connect the two subframe longitudinal supports 3 to one another at the front and rear corner points. The two sub-frame longitudinal bearings 3 extend forward and rearward along the vehicle longitudinal direction x correspondingly beyond the corner joints to form a longitudinal bearing front section 9 and a longitudinal bearing rear section 11 ( image 3 ).

[0029] The subframe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com