A drum automatic cooking machine

An automatic cooking and drum technology, which is applied in the heating device and other directions, can solve the problems of difficult cleaning, too many pots and components, and the inability to cook, and achieve the effect of simple assembly process, avoiding mutual interference, and delicious cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

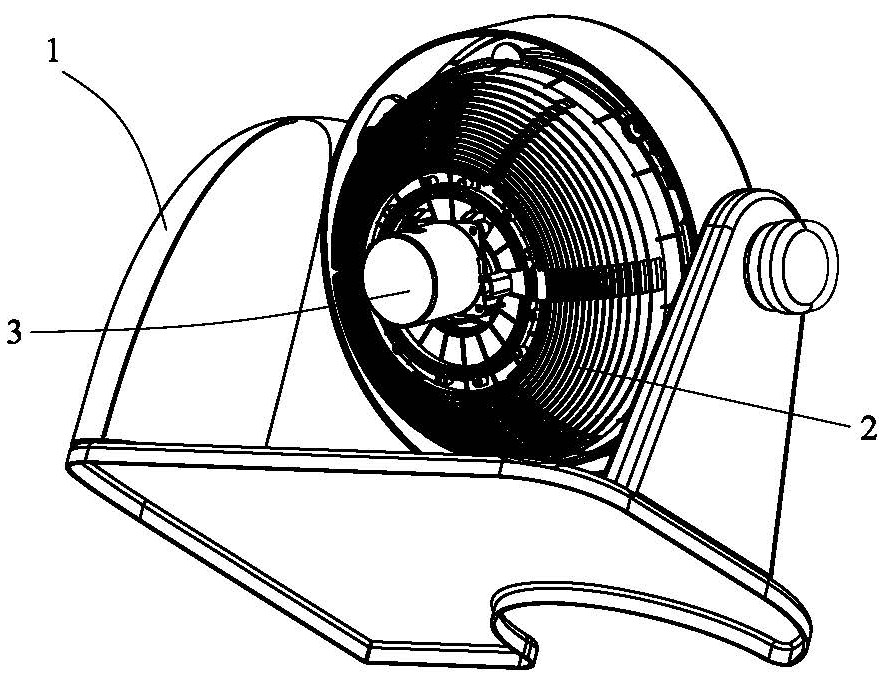

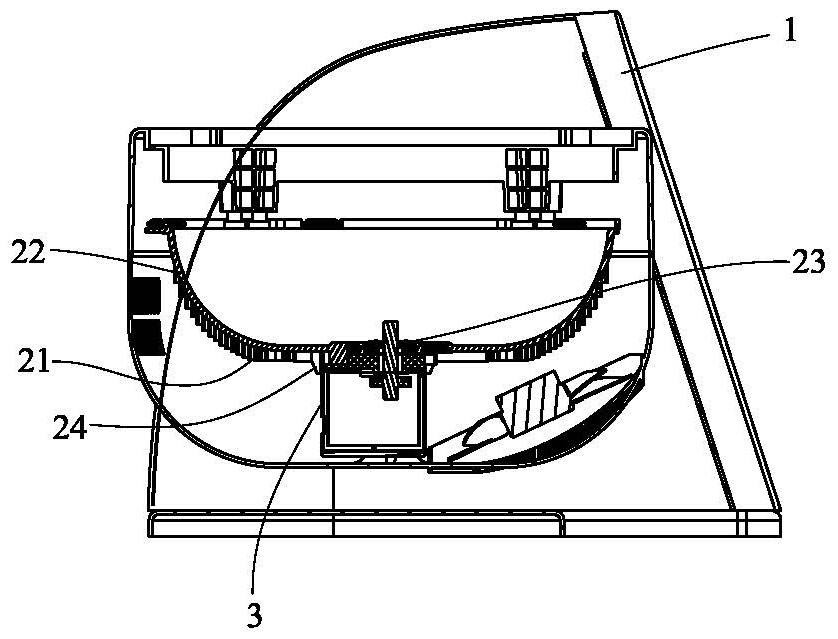

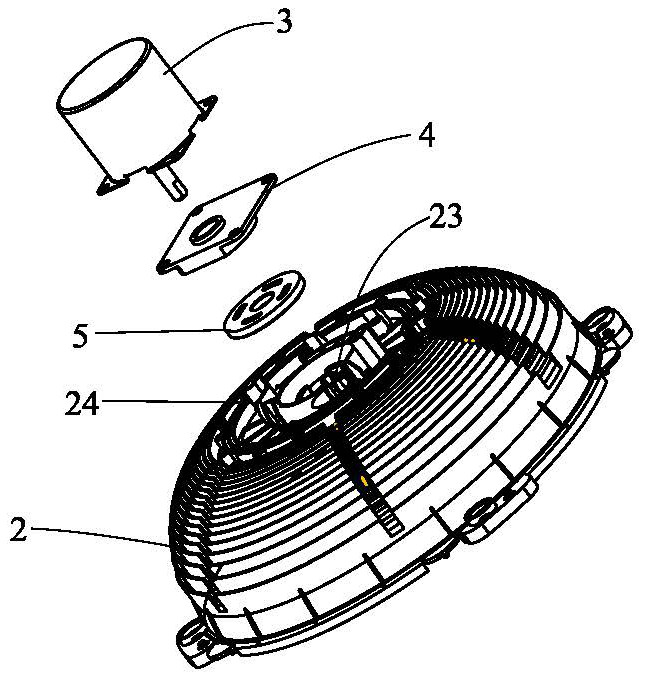

[0033] see figure 1 , figure 2 as well as image 3 As shown, a drum automatic cooking machine according to the present invention includes a body 1 , an electromagnetic coil 2 , a pot (not shown in the figure), and a drive motor 3 for driving the rotation of the pot. The pot is located on the electromagnetic coil 2 .

[0034] The body 1 supports the electromagnetic wire tray 2 and the inner pot, so that the drum automatic cooking machine of the present invention can be tilted when cooking, and can be in a non-cooking state or cooking soup and porridge in a vertical state.

[0035] The electromagnetic coil includes a bottom wall 21 that is a side wall 22 adapted to the shape of the inner pot. The middle part of the bottom wall 21 is provided with a through hole 23 for the output shaft of the drive motor to pass through. The outer periphery of the through hole 23 is provided with a support limiter. Rib 24, the driving motor 3 is fixed within the range limited by the support li...

Embodiment approach 2

[0056] see Figure 4 As shown, the second embodiment of the drum automatic cooking machine of the present invention differs from the first embodiment in that the number of winding layers of the side induction coil 27 is greater than that of the bottom induction coil 26 .

[0057] In this way, it is further ensured that the arc-shaped side wall of the electromagnetic induction coil of the present invention generates more heat than the bottom wall, thereby ensuring the effect of three-dimensional heating.

[0058] Further, the winding layers of the side induction coil 27 are 2-4 layers, and the winding layers of the bottom induction coil 26 are 1-2 layers. Of course, the winding of the side induction coil 27 can also have more local layers, for example, the middle of the side induction coil 27 has more layers than the two sides, or the layers are arranged alternately. In general, it can ensure that the heat of the side induction coil 27 is greater than that of the bottom induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com