A test method for cmos sensor

A technology of CMOS sensor and test method, which is applied in the direction of TV, electrical components, image communication, etc., can solve the problems of CMOS sensor circuit and pixel performance single, less test function, less test quantity, etc., to reduce cost, increase functionality, The effect of improving the convenience of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

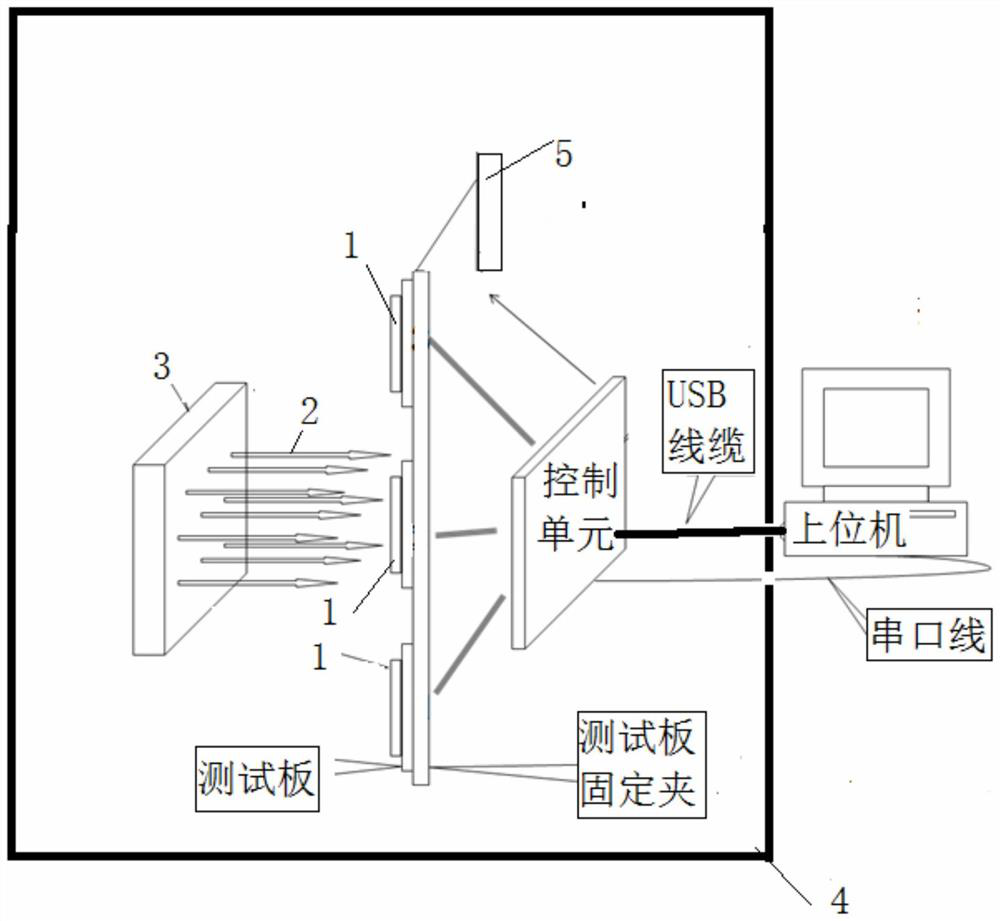

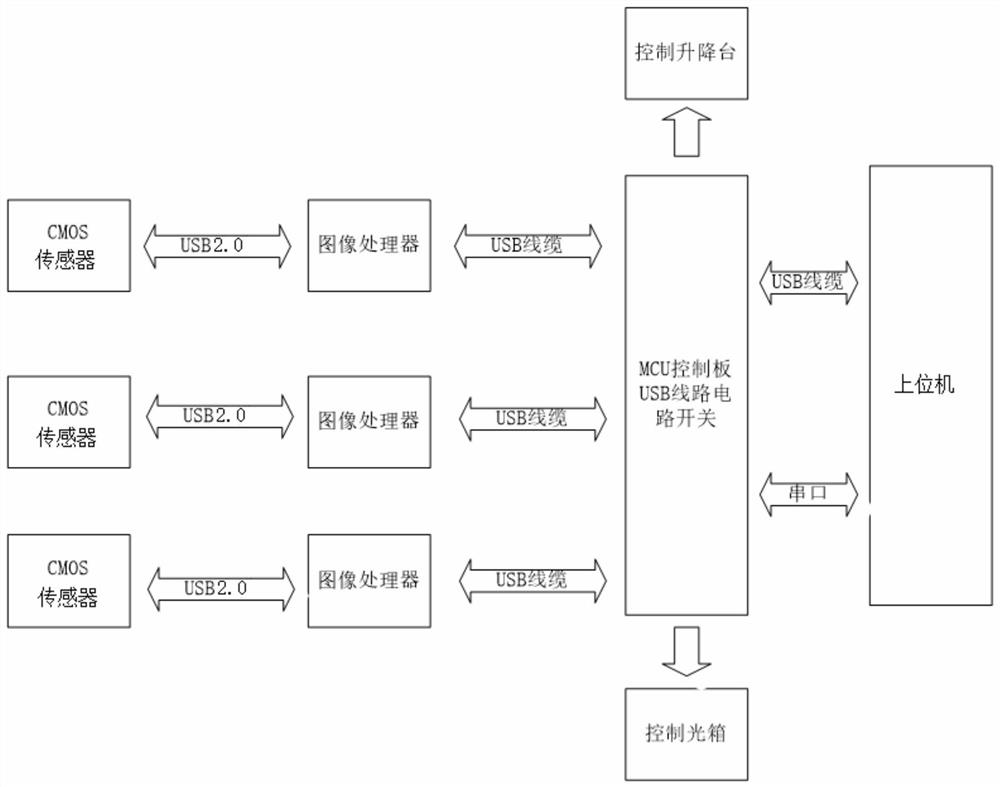

[0056] This embodiment provides a test system for CMOS sensors, such as figure 1 , the test system includes a parallel light light box that provides parallel light, the parallel light light box is a DNP light box; the number is 3 lensless CMOS sensors, and the lensless CMOS sensor corresponds to the position of the parallel light during testing; Describe the test board that no lens CMOS sensor is connected, described test board includes the image sensor that is used to collect signal data; Described no lens CMOS sensor and test board are all fixed on test board holder, and described test board holder is fixedly connected to Lifting platform; the test board is connected to the control unit through USB2.0, the control unit is also connected to the lifting platform, and the control unit is connected to the upper computer through a USB cable and serial port; the upper computer is located in the sealed Outside the light box, the rest of the test system is placed in a sealed dark box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com