High-voltage relay

A high-voltage relay, high-level technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information and other directions, can solve the problems of reducing the service life of the return spring, melting and damage of the return spring, poor reliability of the relay, etc., to extend the service life, Improve reliability and avoid stuck effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

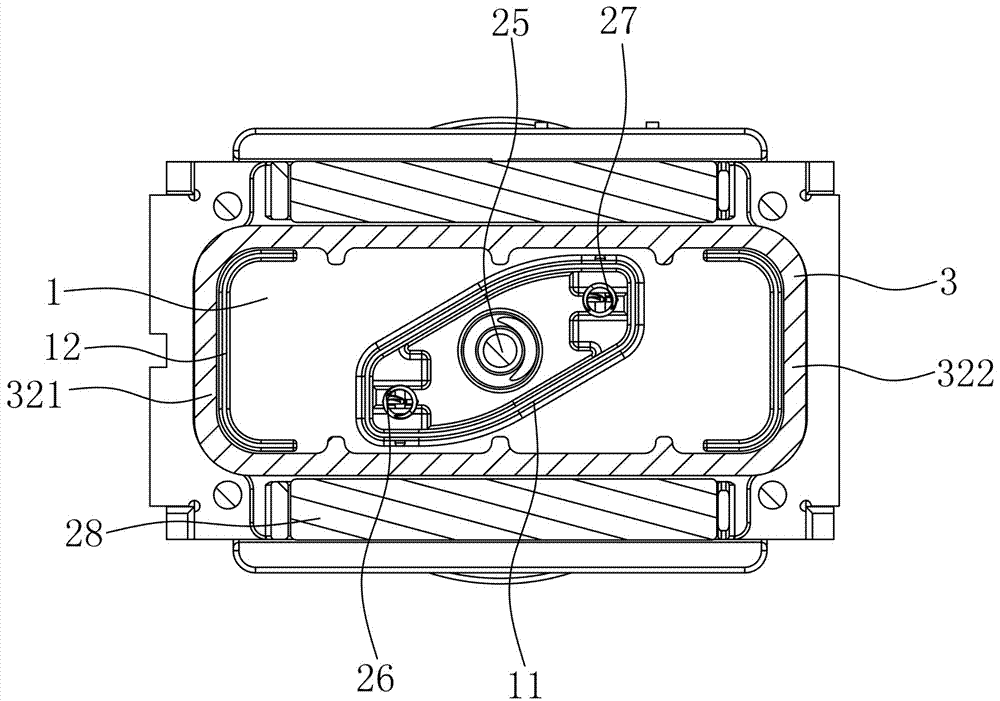

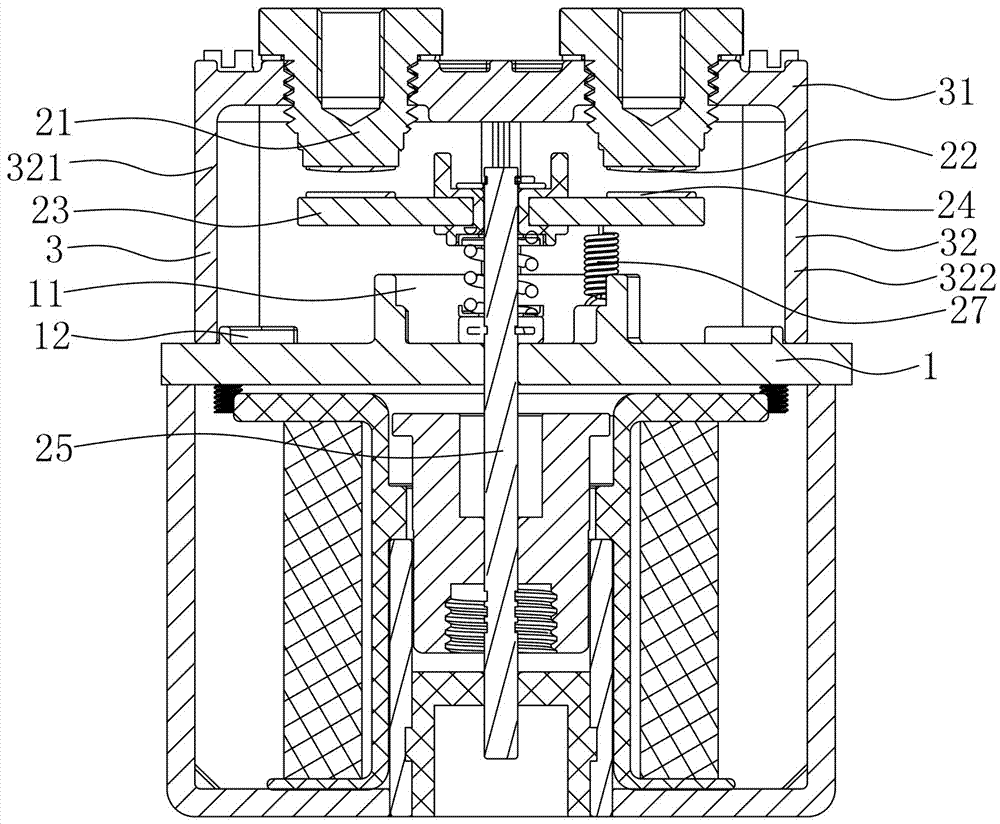

[0030] Depend on figure 1 , figure 2 As shown, a high-voltage relay of the present invention includes a yoke 1, a static contact assembly and a moving contact assembly arranged above the yoke 1, the static contact assembly includes a lead-out 21 and a static contact 22, and the moving contact The assembly includes a moving reed 23 and a moving contact 24, the moving reed 23 is fixed to the upper end of the push rod 25, the lower end of the push rod 25 is located below the yoke 1, and the upper side of the yoke 1 is provided with an insulating cover made of ceramic material sintered 3. The insulating cover 3 cooperates with the yoke iron 1 to form a chamber for accommodating the movable contact assembly and the static contact assembly. The insulating cover 3 includes a top plate 31 and an enclosure 32. The top plate 31 is used to fix the static contact assembly. The yoke 1 is formed with an upwardly extending protection protrusion 11 , the cross section of the protection prot...

Embodiment 2

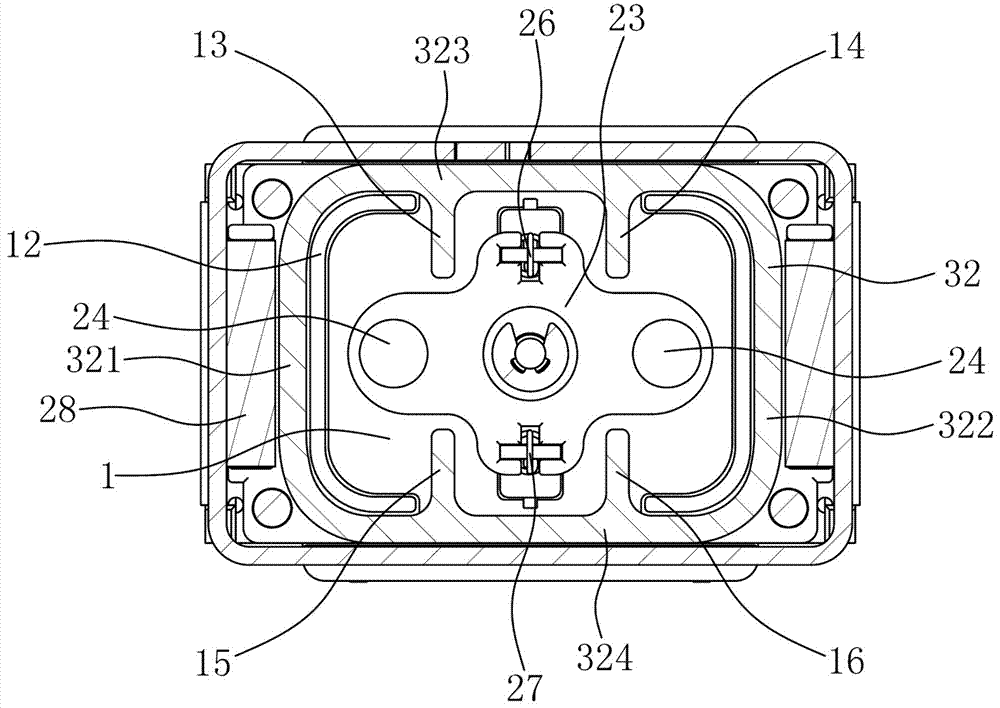

[0035] Depend on image 3 , Figure 4 As shown, a high-voltage relay of the present invention includes a yoke 1, a static contact assembly and a moving contact assembly arranged above the yoke 1, the static contact assembly includes a lead-out 21 and a static contact 22, The movable contact assembly includes a movable reed 23 and a movable contact 24, the movable reed 23 is fixed to the upper end of the push rod 25, the lower end of the push rod 25 is located below the yoke 1, and the upper side of the yoke 1 is provided with a sintered ceramic material. The insulating cover 3, the insulating cover 3 cooperates with the yoke 1 to form a chamber for accommodating the movable contact assembly and the static contact assembly, the insulating cover 3 includes a top plate 31 and an enclosure 32, the top plate 31 is used to fix the static contact As for the point assembly, the yoke 1 is formed with an upwardly extending protection protrusion 11 , the cross section of the protection ...

Embodiment 3

[0039] Depend on Figure 5 , Image 6 , Figure 7 As shown, a high-voltage relay of the present invention includes a yoke 1, a static contact assembly and a moving contact assembly arranged above the yoke 1, the static contact assembly includes a lead-out 21 and a static contact 22, and the moving contact The assembly includes a moving reed 23 and a moving contact 24, the moving reed 23 is fixed to the upper end of the push rod 25, the lower end of the push rod 25 is located below the yoke 1, and the upper side of the yoke 1 is provided with an insulating cover made of ceramic material sintered 3. The insulating cover 3 cooperates with the yoke iron 1 to form a chamber for accommodating the movable contact assembly and the static contact assembly. The insulating cover 3 includes a top plate 31 and an enclosure 32. The top plate 31 is used to fix the static contact assembly. The yoke 1 is formed with an upwardly extending protection protrusion 11 , the cross section of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com