Measurement and control system used for underwater explosion model test of centrifuge

A technology of underwater explosion and model test, which is applied to hydraulic models, testing of machine/structural components, measuring devices, etc., to reduce costs, enhance test repeatability, and improve test efficiency and test capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

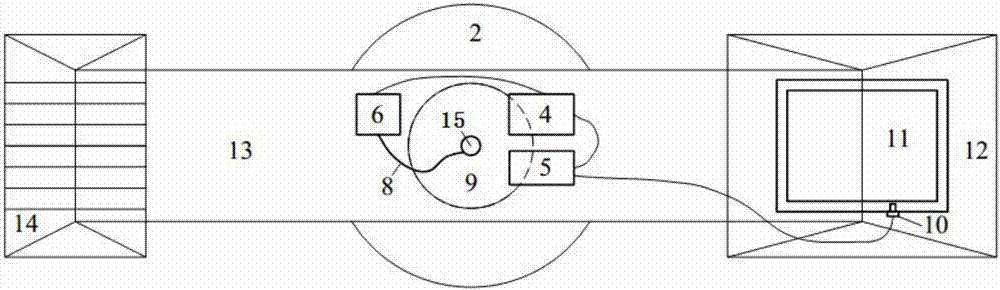

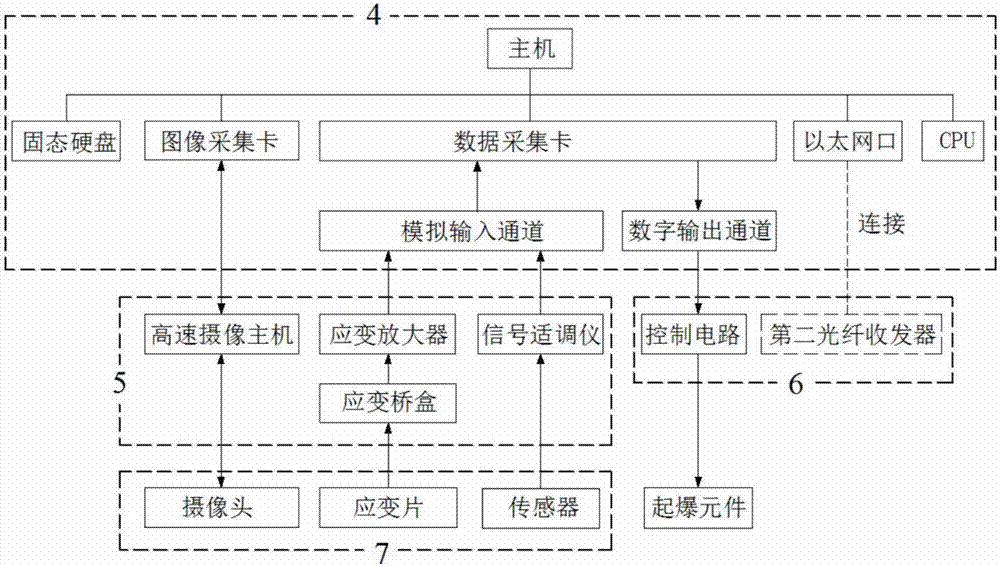

[0025] ginseng figure 1 As shown, the centrifugal force of the centrifuge gradually increases from the centrifuge rotating shaft 9 to the rotating arm 13 to the counterweight hanging basket 14 and the model box hanging basket 12. Initiating components (including detonators, detonating cords, explosives) are arranged on the model box or on the test model, and other instruments, such as the lower computer 4, the control box 6, the regulator subsystem 5 (including the strain amplifier, Sensor signal regulator, high-speed camera host) all need to be arranged on the centrifuge turntable 2 in order to prevent from being unable to work normally due to large centrifugal force.

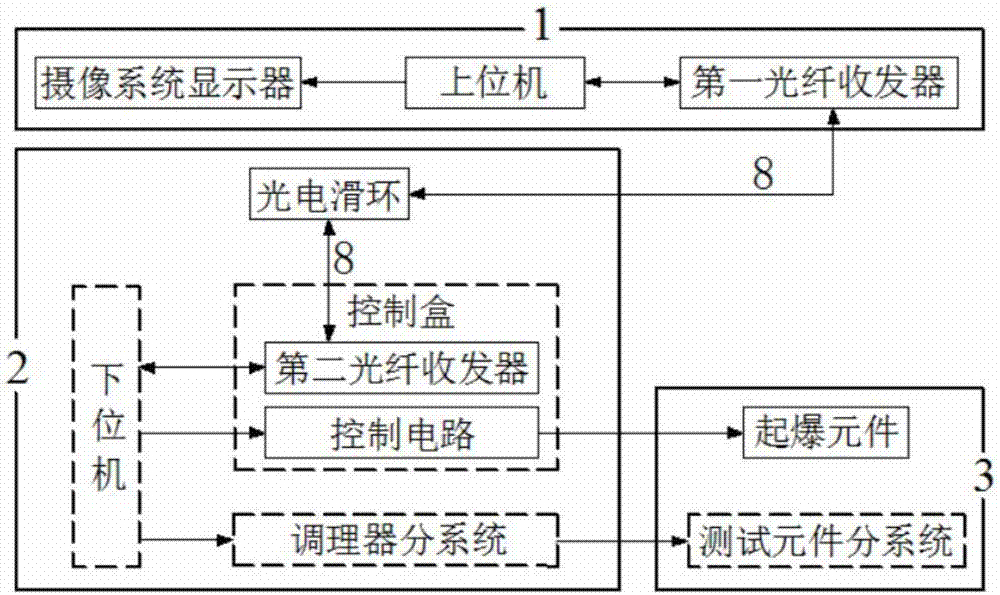

[0026] The upper computer, the monitor of the camera system and the first optical fiber transceiver are located in the ground control room 1; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com