Production system for manufacturing crossbeam or auxiliary beam of wind blade by adopting pull-extrusion molded plate

A technology for sheet production and wind power blades, applied in the field of production systems, can solve problems such as high cost and insufficient performance, and achieve the effects of low cost, scientific and reasonable design, and saving mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

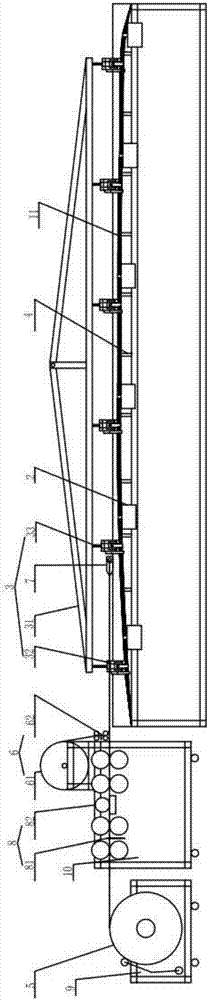

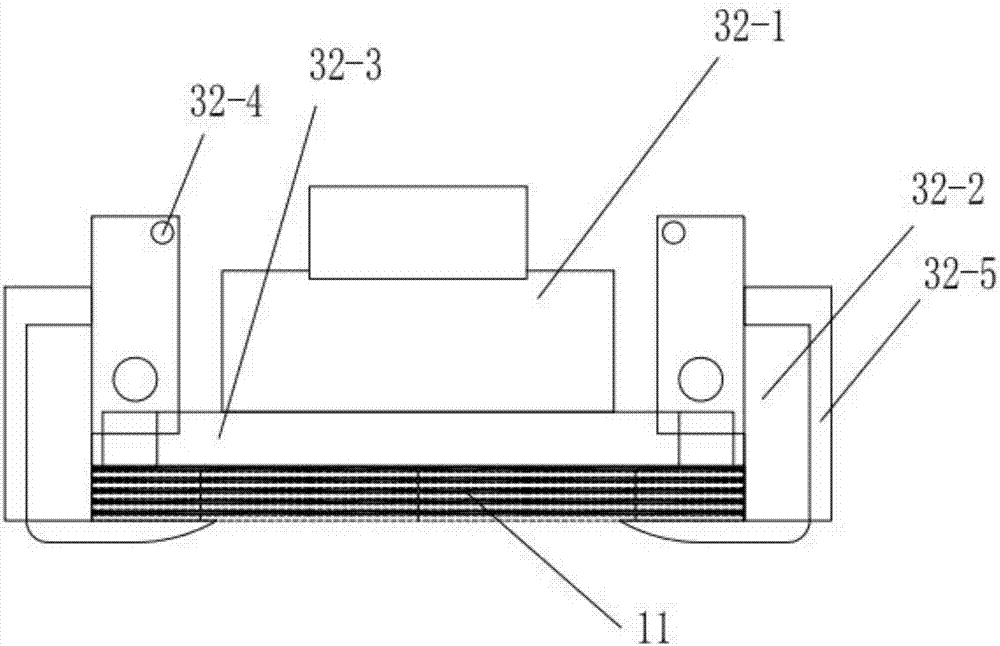

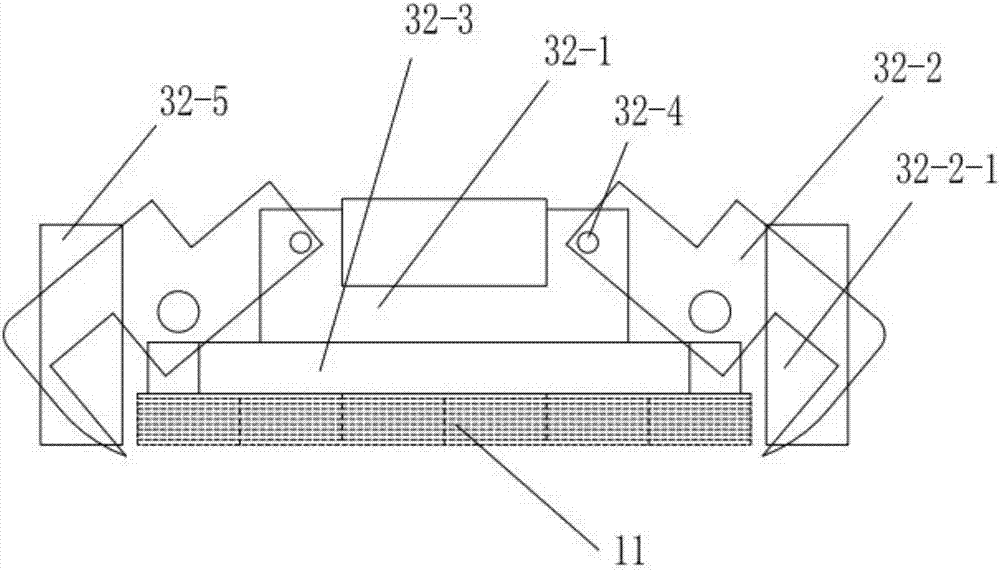

[0030] see figure 1 In this embodiment, the production system for making wind turbine blade beams or auxiliary beams using pultruded plates includes stacking platform 1, binding mechanism 2, lifting mechanism 3, arc adjustment structure 4, automatic plate unwinding mechanism 5, interlayer Automatic cloth unwinding mechanism 6, synchronous traction device 7, plate processing mechanism 8, first mobile trolley 9, second mobile trolley 10 and guide rails; binding mechanism 2 includes multiple, arranged along the length direction of stacking platform 1; lifting The mechanism 3 includes a hoisting and hoisting tool 31, a plurality of spreaders 32 and a telescopic rod 33; the telescopic rod 33 connects the lifting tool 31 and the spreader 32, is a rigid telescopic rod, and corresponds to the number of spreaders 32; The tools 32 are arranged in pairs along the length direction of the stacking platform 1. The stacking platform 1 is provided with a plurality of arc adjustment structures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com