Milling and polishing integrated crawler type industrial robot

An industrial robot, crawler-type technology, used in manipulators, manufacturing tools, etc., can solve problems such as cumbersome programming and repositioning errors in workpiece polishing, achieve excellent off-road performance, low rolling resistance, and solve cumbersome programming and repositioning errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

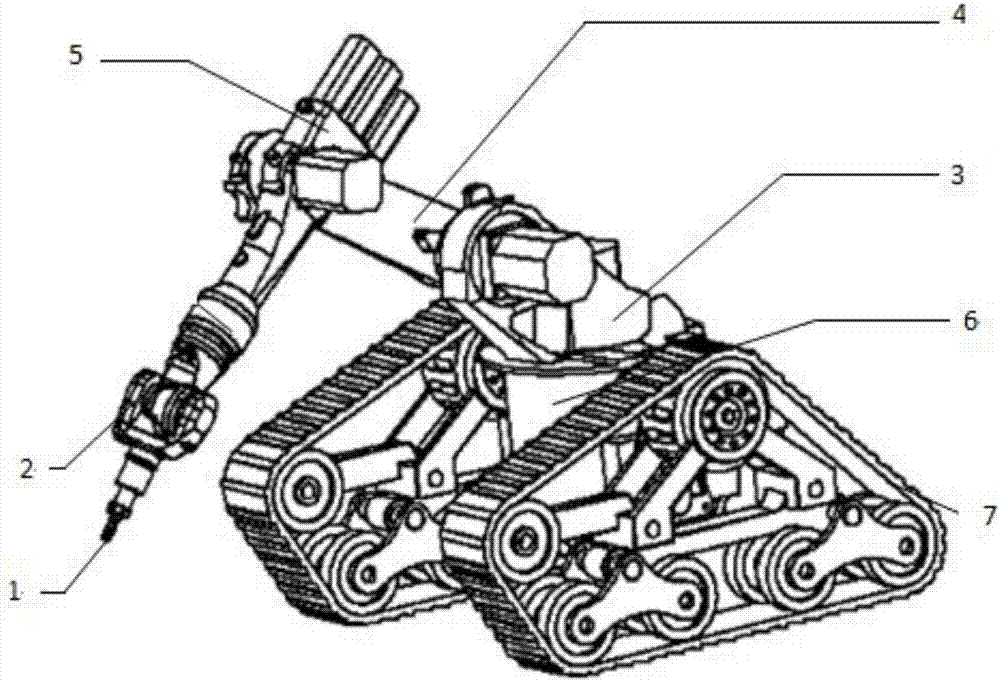

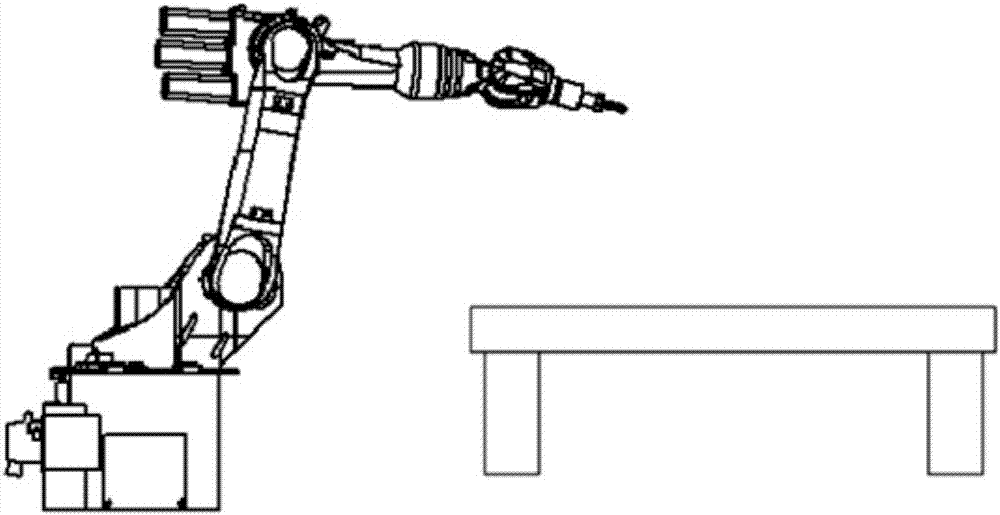

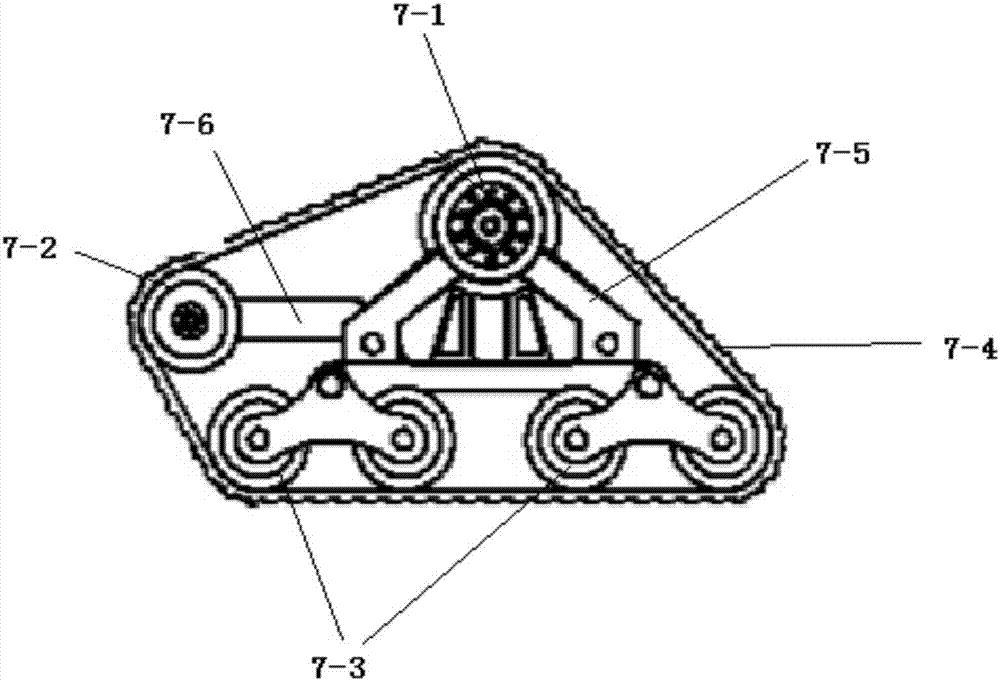

[0018] Such as Figure 1-5 As shown, a crawler-type industrial robot integrating milling and polishing includes a tool changing device 1, a tool angle adjusting device 2, a first mechanical arm 3, a second mechanical arm 4, a third mechanical arm 5, a base 6 and two A group of traveling mechanisms 7, the two groups of traveling mechanisms 7 are respectively arranged on both sides of the base 6 through motors, and the first mechanical arm 3 is installed on the top of the base 6 through a steering gear to realize a 360° rotation around the z axis. One end of the second mechanical arm 4 is connected with the first mechanical arm 3 through a steering gear to realize a 360° rotation around the x-axis; the third mechanical arm 5 is connected with the other end of the second mechanical arm 4 through a steering gear to realize For 360° rotation around the y-axis, the tool ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com