Vegetable stripping device and laver processing device

A driving device and transfer device technology, applied in food science and other fields, can solve problems such as low production efficiency and poor reliability, and achieve the effect of reducing overall cost and improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

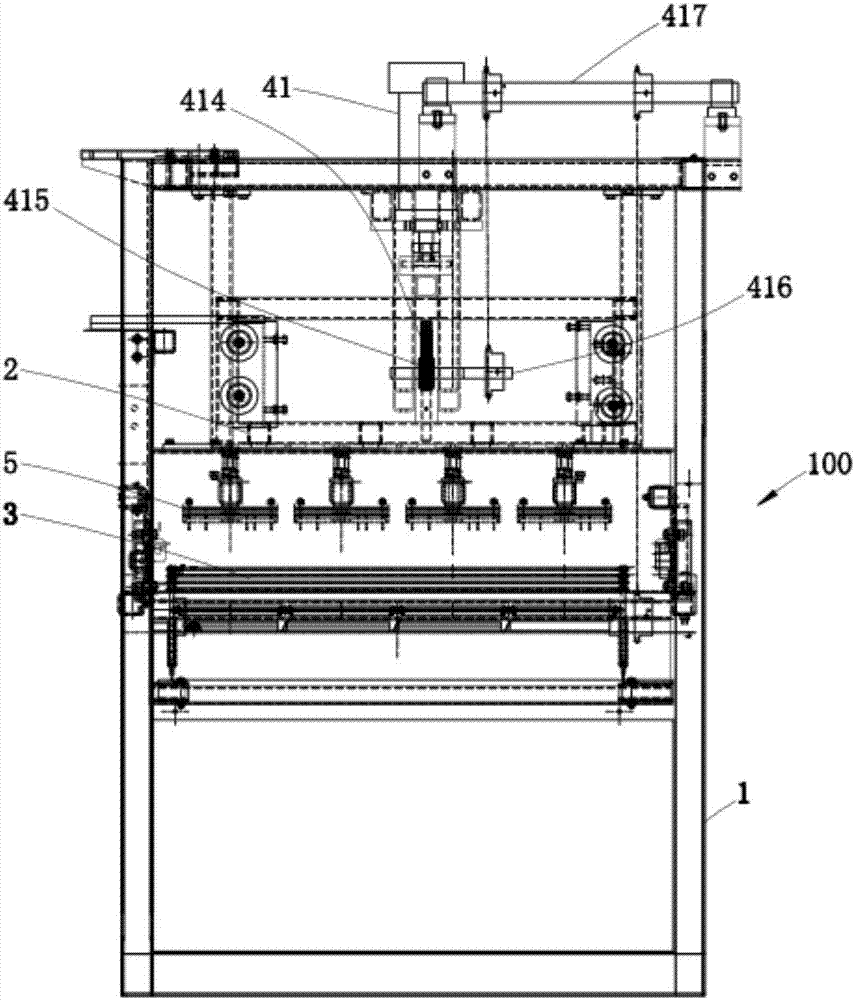

[0031] Such as figure 1 with figure 2 As shown, the present invention provides a vegetable peeling device. The vegetable peeling device 100 includes: a frame 1, a lifting mechanism 2, a transfer platform (not shown in the figure), a transfer device 3 and a driving device.

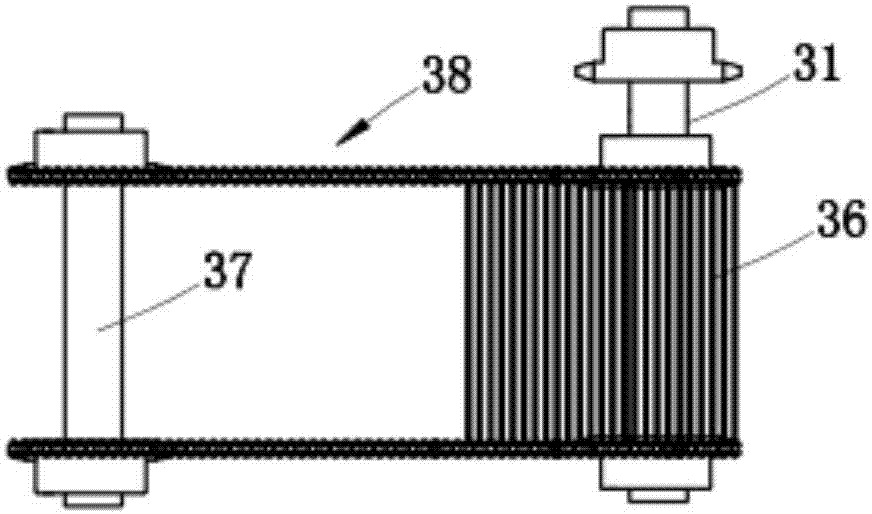

[0032] Specifically, the lifting mechanism 2 is arranged on the frame 1 so as to move up and down, and the lifting mechanism 2 is provided with at least one thorn vegetable mechanism 5 . The transfer platform is movably arranged below the vegetable stabbing mechanism 5, and at least one material tray is arranged on the delivery platform, and the vegetable stabbing mechanism 5 is used for stabbing and releasing the material cake in the tray. Wherein, there can be one or more thorn vegetable mechanisms 5, and there can be one or more charging trays. The transfer device 3 is located below the spinach mechanism 5 , and the transfer device 3 can rotate around the delivery platform. The transfer device 3 is us...

Embodiment 2

[0044] The present invention provides a vegetable peeling device, the structure of which is basically the same as that of Embodiment 1, the difference being that:

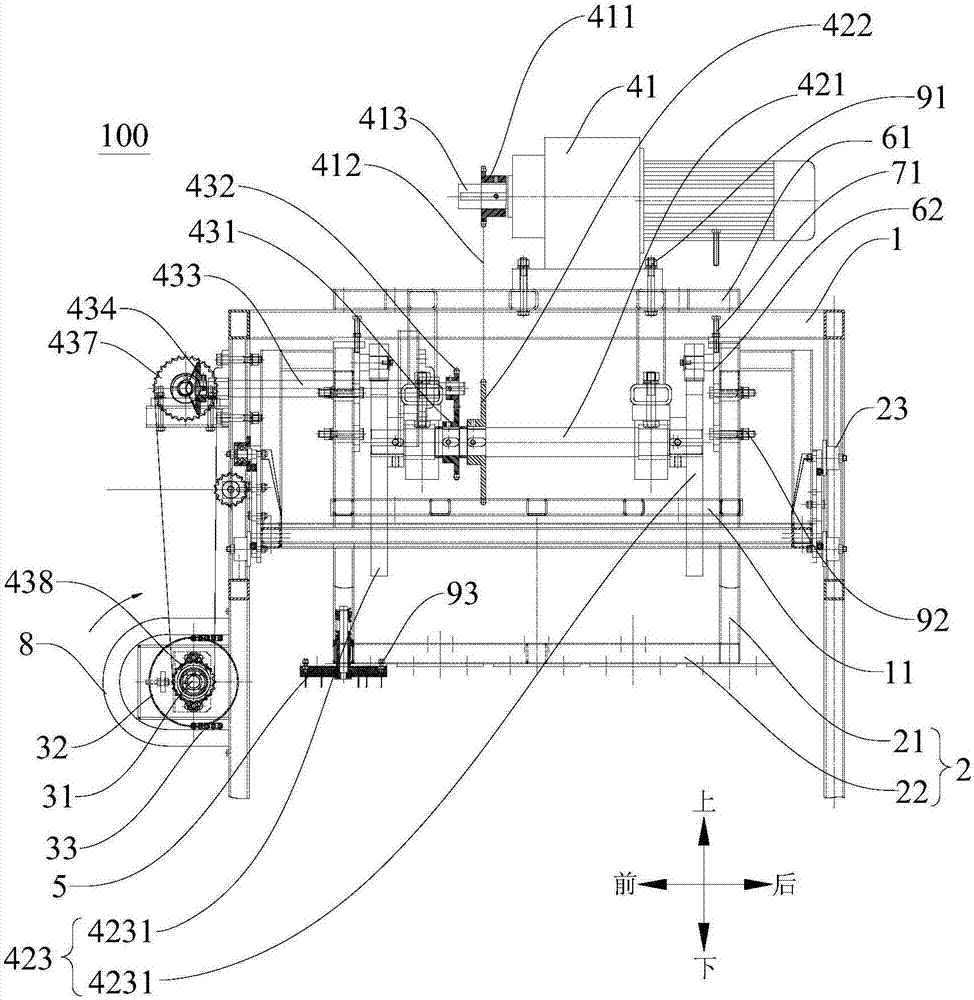

[0045] Such as image 3 with Figure 4 As shown, the driving device includes a driving source 41, a first driving assembly and a second driving assembly, the driving source 41 is linked with the first driving assembly, the second driving assembly is linked with the first driving assembly, and the first driving assembly is connected with the lifting mechanism 2 , the first drive assembly is used to drive the lifting mechanism 2 to move up and down, the second drive assembly is connected to the transfer device 3, and the second drive assembly is used to drive the transfer device 3 to rotate.

[0046] That is to say, the drive source 41 can drive the first drive assembly to work, and then the first drive assembly drives the lifting mechanism 2 to move up and down. At the same time, the first drive assembly can drive ...

Embodiment 3

[0078] The present invention also provides a laver processing equipment, including the vegetable peeling device 100 described in Embodiment 1 or Embodiment 2, which improves the overall performance of the laver processing equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com