Analog simulation method for automobile storage battery sizing

A simulation and battery technology, applied in the automotive field, can solve problems such as battery life reduction, cost waste, frequent vehicle power loss, etc., to avoid one-sidedness and accurate calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

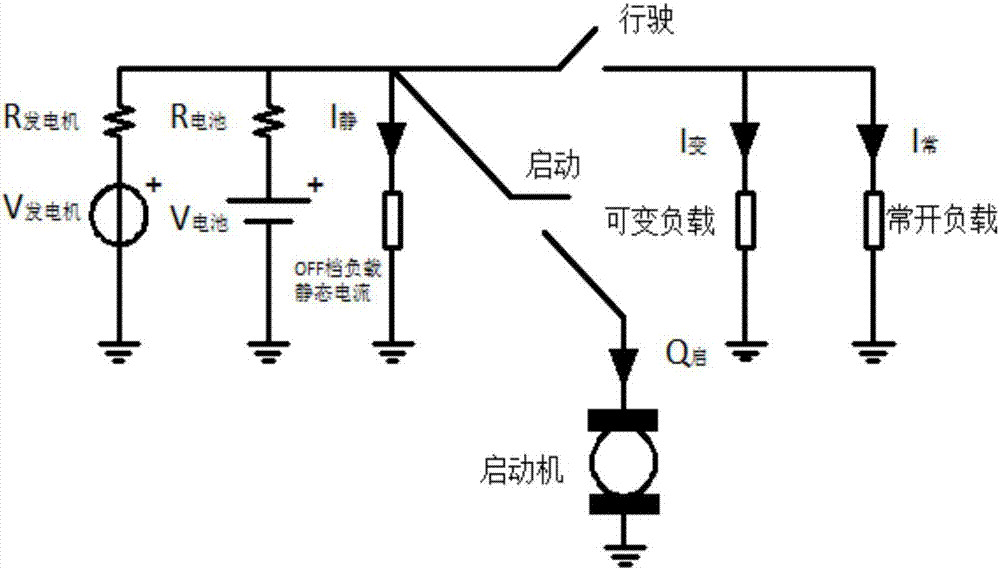

[0039] Combine first figure 1 Briefly introduce the principle of the power system of the vehicle. The circuit includes a generator, a battery and some parallel electrical loads. Partial loads, such as normally open loads, are always in working condition during the driving of the whole vehicle (such as ECU, TCU, electronic steering, instrumentation and other electronic devices necessary for driving). There are also some loads that can be turned on or off according to the driving conditions of the vehicle, the needs of the driver or passengers (such as headlights, turn signals, air conditioners, blowers, audio, seat heating, etc.), this part of the load is variable load. In addition, some loads continue to work after the car is locked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com