Method for taking out die pouring gate buffering pit movable materials

A mold and live material technology, which is applied in the field of casting mold making, can solve the problems of material loss, easily damaged sand core, time waste, etc., and achieve the effects of improving efficiency, reducing costs, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

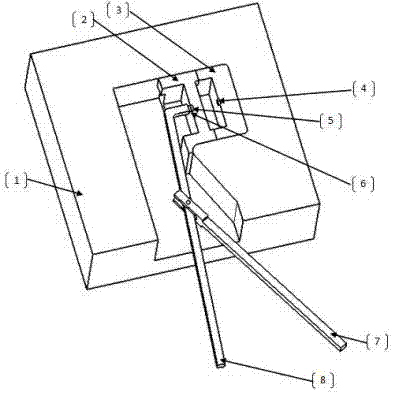

[0015] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following in conjunction with the attached figure 1 The present invention is further analyzed.

[0016] like figure 1 Shown, a kind of method for taking out mold sprue buffer nest live material, comprises the following steps:

[0017] Step 1: Using the principle of leverage, the tooling support rod 7 and the tooling rotating rod 8 are produced, and a magnet is fixed at one end of the tooling rotating rod 8; the tooling rotating rod 8 and the tooling supporting rod 7 are connected by a rotatable shaft;

[0018] Step 2. When designing each live material, the live material is designed to be hollow, and a magnet is fixed in the middle of the live material in advance, and the magnetic poles are calculated; the live material is one or more;

[0019] Step 3, when taking the loose piece, extend the end of the rotating rod with the magnet into the cavity, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com