Special high-efficiency stirrer for conductive slurry

A technology of conductive paste and mixer, which is applied to mixers with rotating stirring devices, mixers, dissolution, etc., which can solve the problems of aggregate deposition, electrical conductivity, field emission performance degradation, and inability to disperse large aggregates. , to achieve the effect of improving the efficiency of breaking up, improving the efficiency of use, and increasing the cutting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

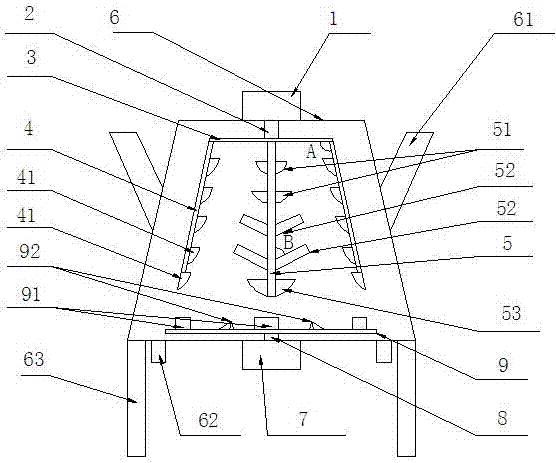

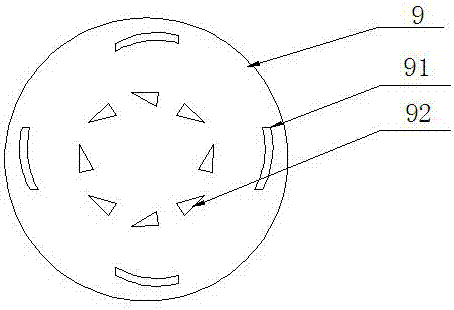

[0026] A special high-efficiency mixer for conductive paste, comprising a mixer shell, wherein the mixer shell has a round truncated cone structure with a narrow top and a wide bottom. The interior of the mixer shell is a hollow structure, and both sides of the mixer shell are provided There is a feed inlet, supporting feet are provided on both sides of the bottom of the mixer shell, and a discharge port is provided at both ends of the bottom of the mixer shell; a first motor is arranged at the center of the top of the mixer shell, and The center of the bottom of the mixer shell is provided with a second motor; the inside of the mixer shell is provided with a first motor shaft, a horizontal stirring rod, an oblique stirring rod, a vertical stirring rod, a second motor shaft and a bottom rotating disk,

[0027] The top of the first motor shaft is connected to the first motor, and the bottom is extended into the inside of the mixer shell to weld the horizontal stirring rod, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com