Wound storage battery with symmetric composite electrodes and perforated collector plates

A composite electrode and collector plate technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problems of uneven current distribution, low current conduction capability, poor performance, etc. Method economy, mechanical strength and anti-vibration performance improvement, effect of reducing battery temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

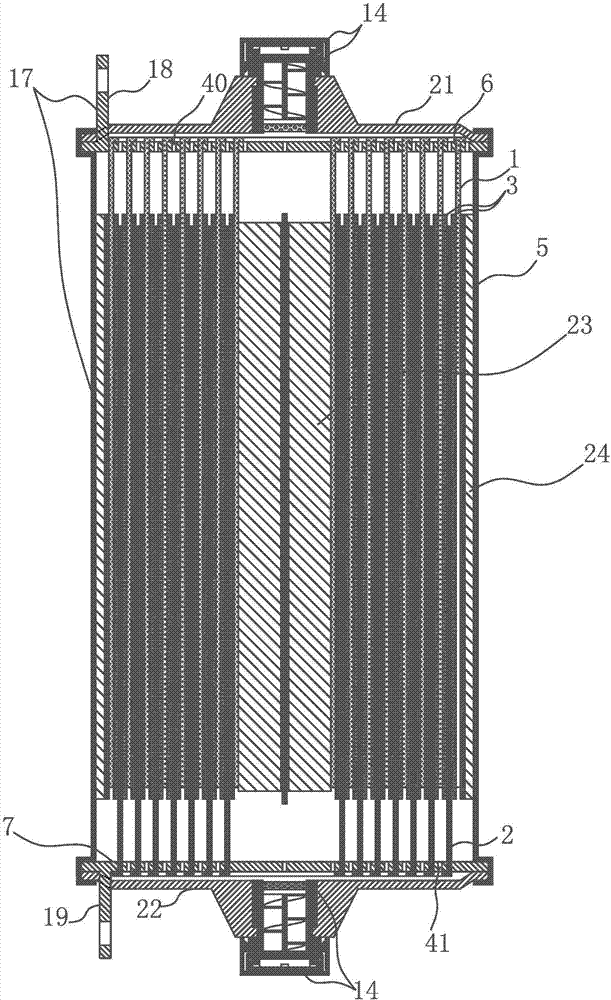

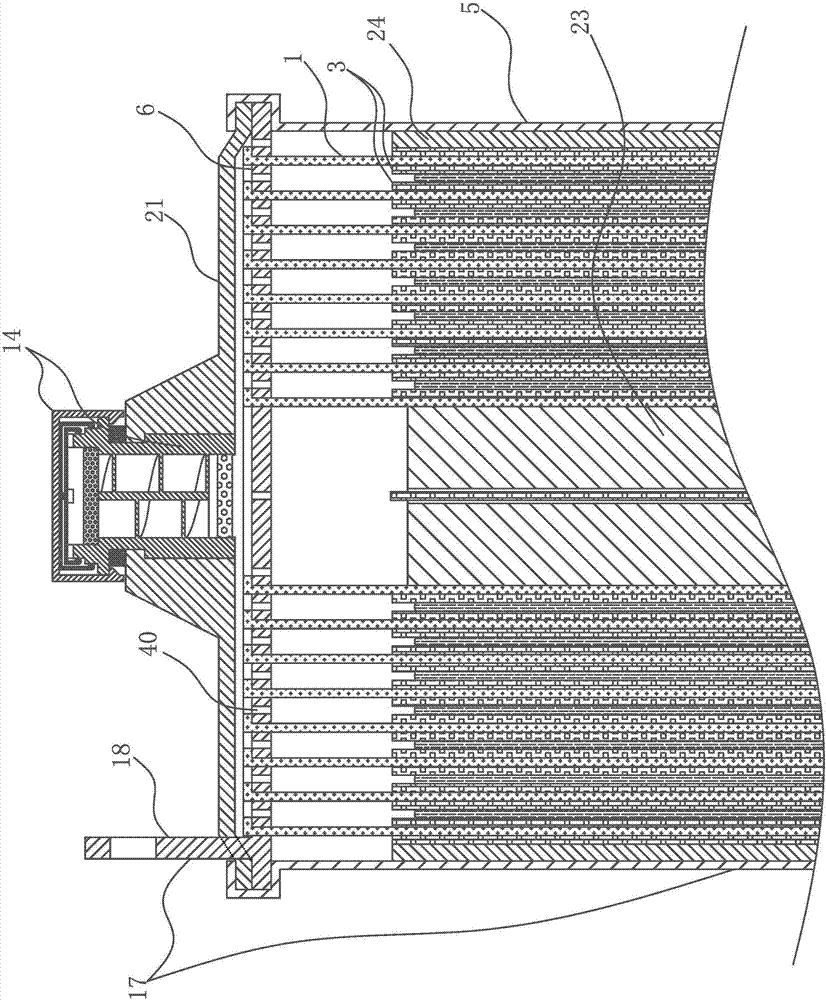

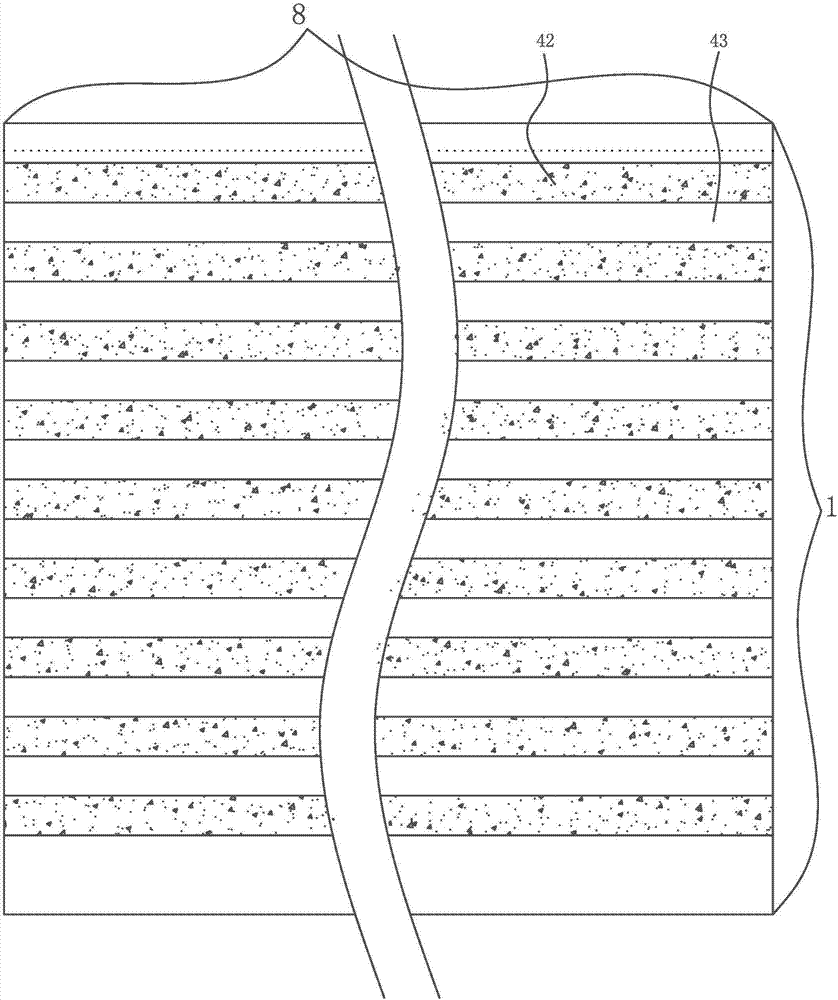

[0019] Such as Figure 1-9 As shown, a winding storage battery with a symmetrical composite electrode having a collector disc, comprising a battery casing (5) and a cell (33), is characterized in that: the cell (33) is composed of a positive electrode sheet (1), a negative electrode sheet ( 2) and the separator (3) positioned between the positive electrode sheet and the negative electrode sheet is wound into a columnar body by the battery core reel (23), and a positive electrode collector plate ( 6) and the negative current collecting plate (7); the positive electrode sheet (1) is provided with a positive electrode continuous lug (8 ); the negative pole piece (2) is provided with a pole lug (9) equal to the length of the negative pole piece (2) at the top of the negative pole current collecting plate (7); the positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com