Vapour diffusion coefficient testing method and vapour diffusion coefficient testing device

A water vapor diffusion and testing device technology, which is applied in the electronic field, can solve problems such as low efficiency, large deviation, and long time consumption, and achieve the effects of reducing computational complexity, maintaining stable boundary conditions, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

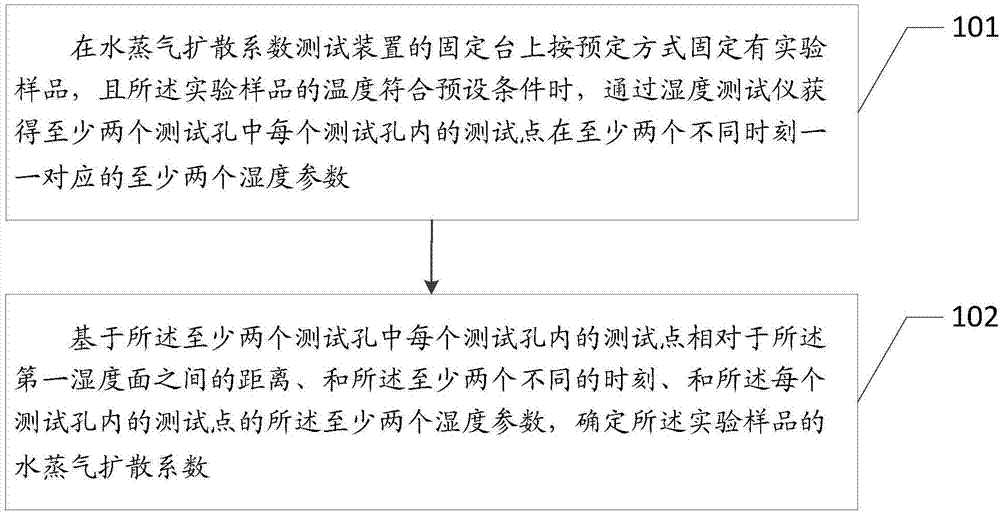

[0051] Please refer to figure 1 , Embodiment 1 of the present application provides a water vapor diffusion coefficient testing method, comprising:

[0052] Step 101: An experimental sample is fixed in a predetermined manner on the fixed table of the water vapor diffusion coefficient testing device, and when the temperature of the experimental sample meets the preset conditions, each of the at least two test holes is obtained by a humidity tester At least two humidity parameters correspond one-to-one to at least two test points within at least two different moments.

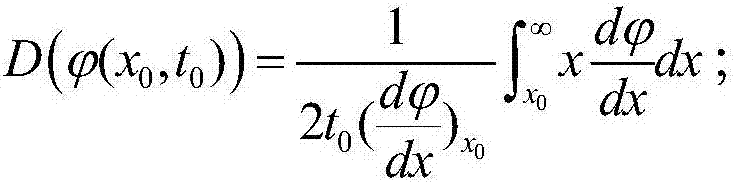

[0053] Step 102: using the processing device based on the distance between the test points in each of the at least two test holes relative to the first humidity surface, the at least two different times, and the each The at least two humidity parameters of the test points in the test holes are used to determine the water vapor diffusion coefficient of the experimental sample.

[0054] Wherein, the experimental s...

Embodiment 2

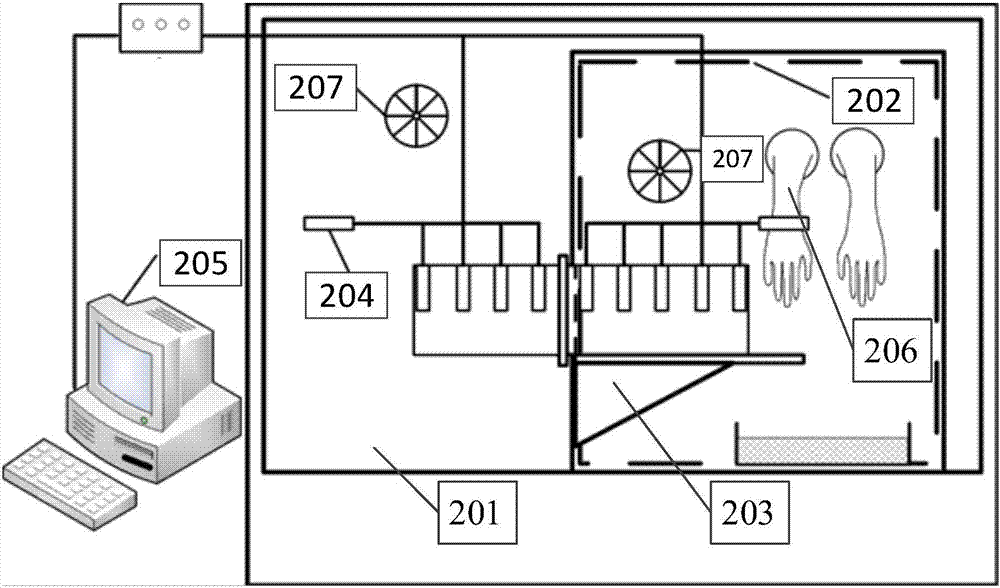

[0082] Please refer to figure 2 , Embodiment 2 of the present application provides a water vapor diffusion coefficient testing device, comprising:

[0083] The first environmental chamber 201, the chamber has a first humidity;

[0084] a second environmental chamber 202, adjacent to the first environmental chamber 201, having a second humidity less than the first humidity in the chamber;

[0085] The fixed stage 203 is used to fix the experimental sample between the first environmental chamber 201 and the second environmental chamber 202, wherein the experimental sample is passed through the first humidity surface oppositely arranged on the sample to be tested. and other surfaces other than the second humidity surface are evenly coated with a sealant, and at least two test holes are formed on the third surface of the sample to be tested, the inside of the test hole includes a test point, the The connection line between the test points of each test hole in at least two test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com