A split channel type pumping station regulating pool

A technology of regulating tanks and diverter tanks, which is applied in the configuration of pumping stations, water supply tanks, buildings, etc., can solve the problems of large hydraulic loss at the turning, large water surface drop at the head and tail of the regulating tank, and low space utilization. Achieve the effect of reducing local hydraulic loss, facilitating uniform inflow, and reducing unstable vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

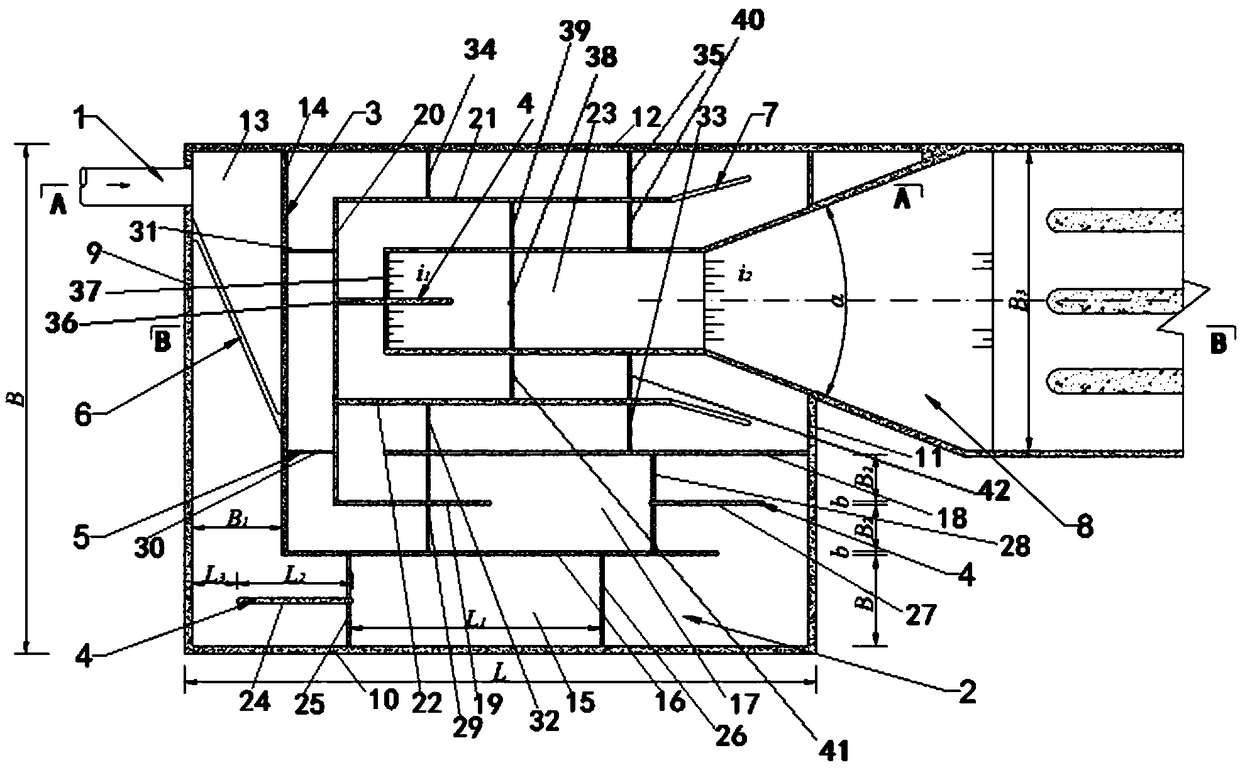

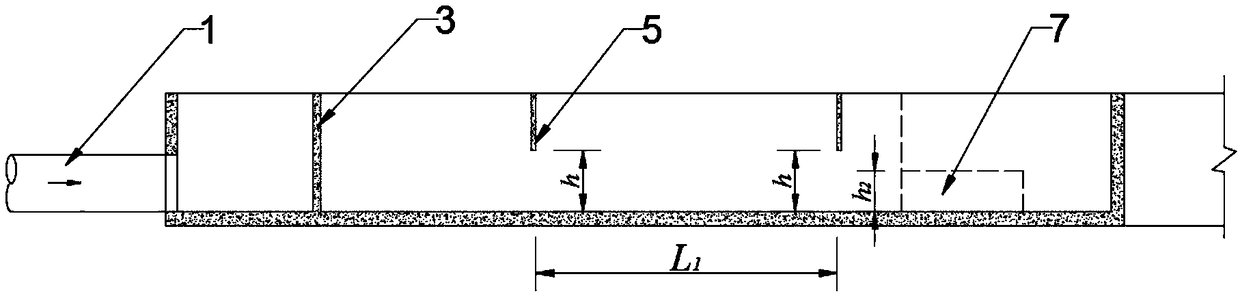

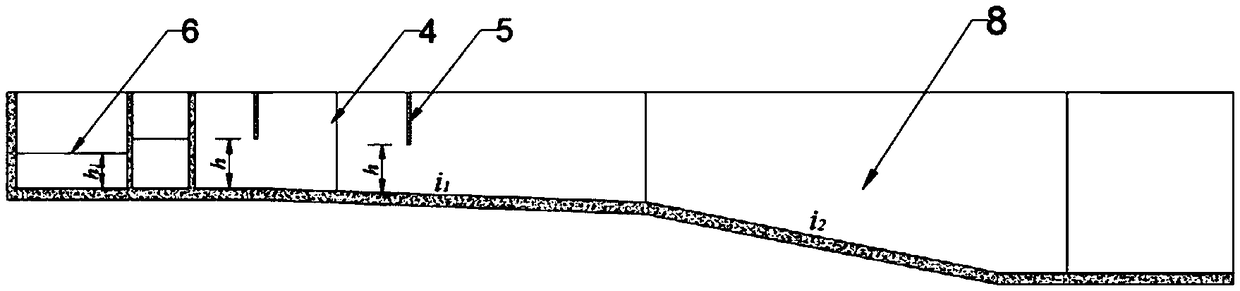

[0036] Such as Figure 1 ~ Figure 4 As shown, a shunt channel type pumping station regulating tank includes a regulating tank with a rectangular outer contour. 8 connected, the inside of the regulating pool is separated by a partition wall 3 into a circuitous flow tank 2 connecting the water inlet and the water outlet, and the flow tank 2 is provided with a deflector 4 for diverting flow and a vertical partition for adjusting the flow rate 5.

[0037] The launder 2 includes several transverse launders and longitudinal launders; the side wall of the regulating tank is surrounded by the left side wall 9, the front side wall 10, the right side wall 11 and the rear side wall 12, and the water inlet pipe 1 is located at On the left side wall 9 and close to the rear side wall 12, the water inlet pipe 1 communicates with the first transverse flow groove 13, and the first transverse flow groove 13 is formed by the left side wall 9 and the left side wall. The first partition wall 14 ...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is only: B 2 =0.6B 1 , h=H,L 1 =7h,L 2 = 1.5B 1 .

Embodiment 3

[0053] The difference between this embodiment and embodiment 1 is only: B 2 =0.4B 1 , h=0.8H, L 1 =6h,L 2 =B 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com