Hand-push type small-sized snow remover

A hand-push, snow removal technology, applied in the direction of engines, mechanical equipment, cleaning methods, etc., can solve the problems of low efficiency, high cost, and incomplete cleaning of manual snow removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

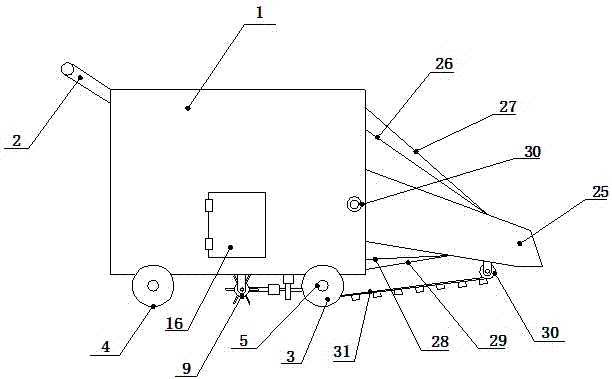

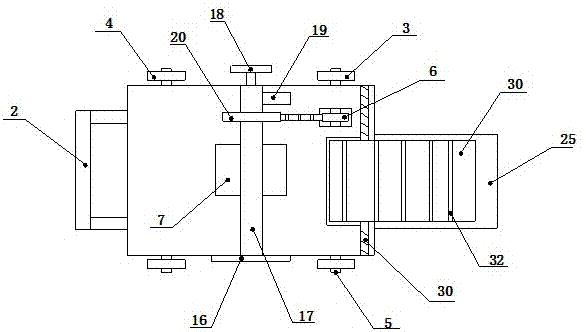

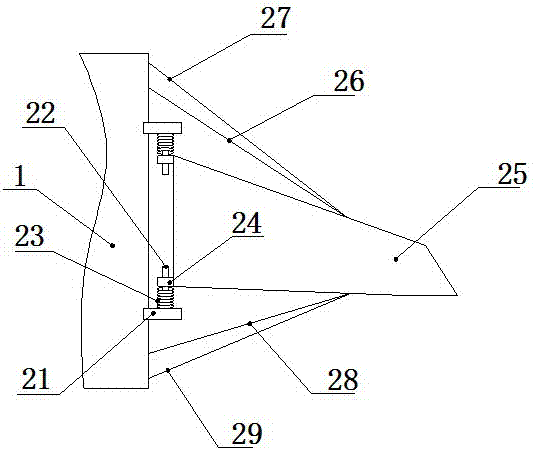

[0022] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, a hand-push small-sized snow blower includes a car shell 1, an armrest 2 is arranged on the left side of the upper part of the car shell 1, and a driving wheel 3 and a driven wheel 4 are respectively provided at the bottom of the car shell 1. , the driving wheel 3 is connected with a driving shaft 5, the outer wall of the driving shaft 5 is sleeved with a driving sprocket 6, the lower side of the car shell 1 is provided with a bottom door 7, the bottom door 7 A booster system A matched with the bottom door 7 is provided below, the booster system A is provided with a transmission shaft 8, and the two ends of the transmission shaft 8 are respectively connected with a fan wheel 9 and a crankshaft 10, and the crankshaft 10 is connected with a connecting rod 11, the other end of the connecting rod 11 is connected with an inflator 12, and the air outlet end of the inflator 12 is connected with a high-...

Embodiment 2

[0025] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a hand-push small-sized snow blower includes a car shell 1, an armrest 2 is arranged on the left side of the upper part of the car shell 1, and a driving wheel 3 and a driven wheel 4 are respectively provided at the bottom of the car shell 1. , the driving wheel 3 is connected with a driving shaft 5, the outer wall of the driving shaft 5 is sleeved with a driving sprocket 6, the lower side of the car shell 1 is provided with a bottom door 7, the bottom door 7 A booster system A matched with the bottom door 7 is provided below, the booster system A is provided with a transmission shaft 8, and the two ends of the transmission shaft 8 are respectively connected with a fan wheel 9 and a crankshaft 10, and the crankshaft 10 is connected with a connecting rod 11, the other end of the connecting rod 11 is connected with an inflator 12, and the air outlet end of the inflator 12 is connected with a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com