Integrated water path structure of water purifier

A technology that integrates waterways and water purifiers. It is used in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. It can solve problems such as mutual penetration of waterways, poor product versatility, and unfavorable technology promotion and application. , to achieve the effect of neat and orderly structure, stable and reliable use, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

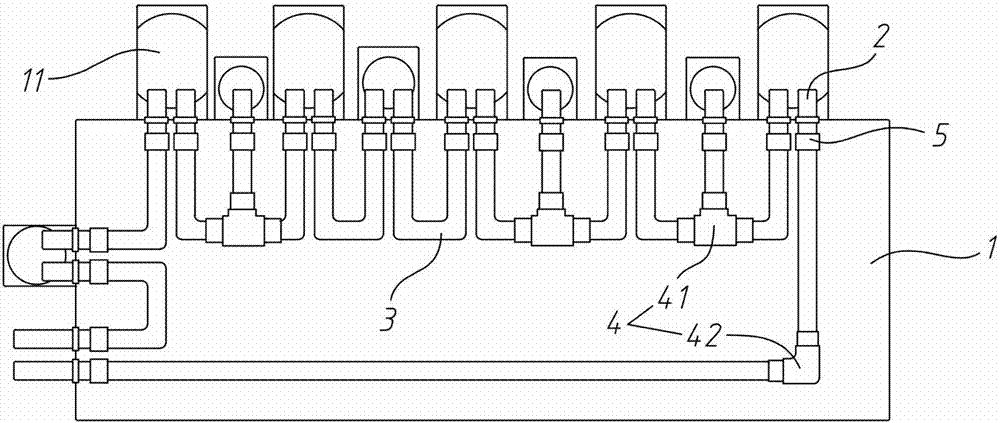

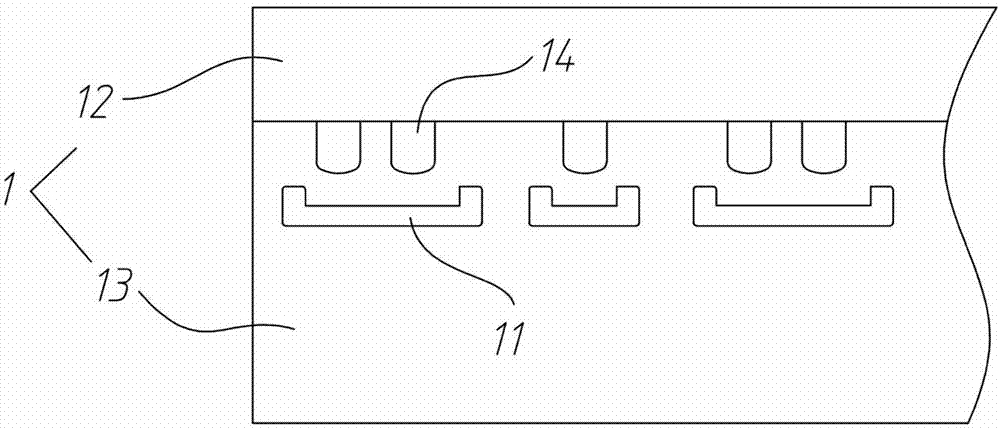

[0022] refer to Figure 1 to Figure 7 The integrated waterway structure of the water purifier shown includes a box-shaped casing 1 , several connectors 2 , and soft water pipes 3 and pipe fittings 4 connecting the connectors 2 . The outer wall of the housing 1 is provided with several mounting brackets 11 for installing the filter element of the water purifier and each control and detection device. The position and quantity of the mounting bracket 11 can be a standard general design. When different numbers of filter elements or different When controlling the detection device, it only needs to be installed on the corresponding installation bracket 11 . The pipe fitting 4 and the soft water pipe 3 are placed in the housing 1, the connector 2 is fixed on the housing 1 and one end protrudes from the housing 1, and the connector 2 protrudes One end of the housing 1 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com