Induction Control System for Tower Cranes

A technology of induction control and tower crane, which is applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of high risk for tower crane operators, not buying insurance, prone to falling accidents, etc., to achieve safety guarantee and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

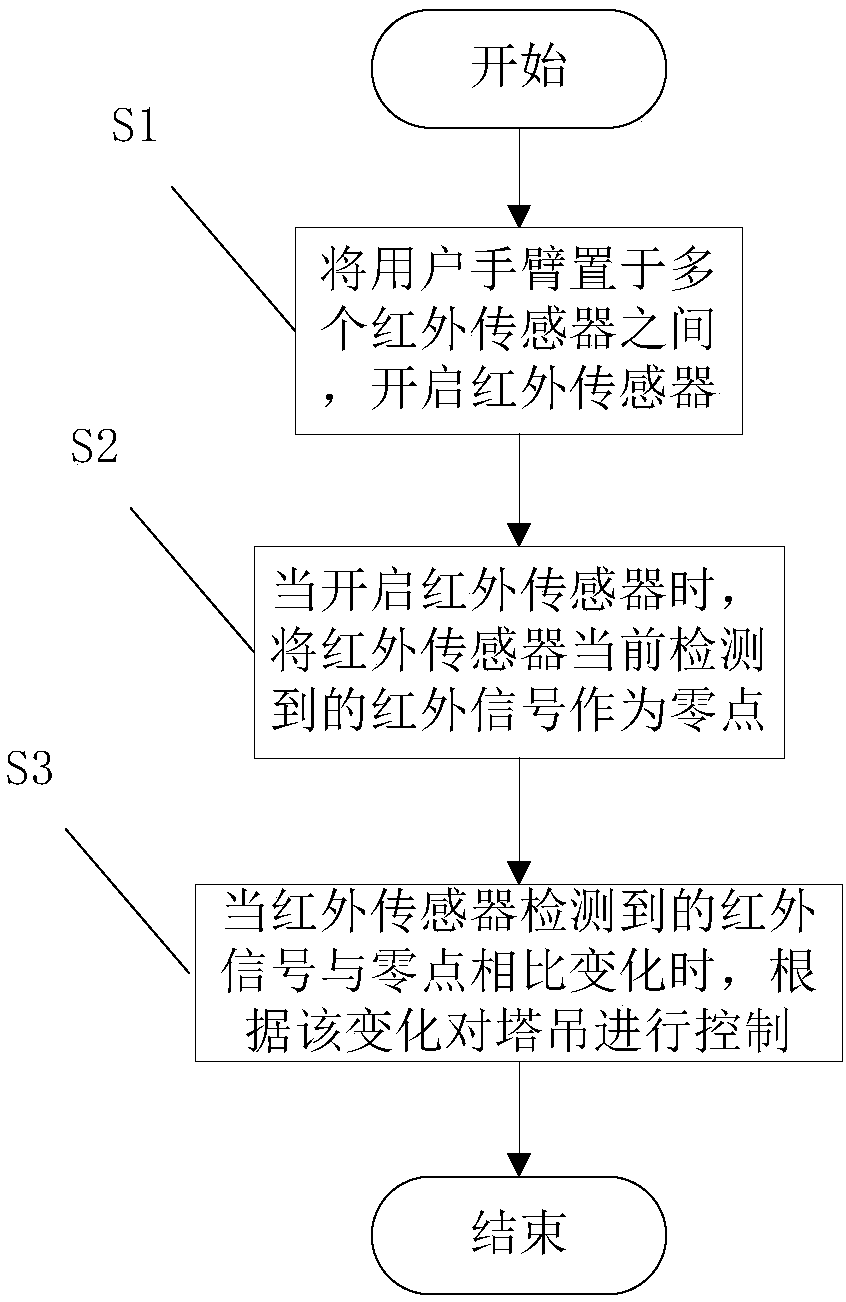

[0022] Such as figure 1 As shown, the induction control system for the tower crane of the present invention includes the following steps: S1: place the user's arm between multiple infrared sensors and turn on the infrared sensor; S2: when the infrared sensor is turned on, the current detected by the infrared sensor The infrared signal is regarded as the zero point; S3: When the infrared signal detected by the infrared sensor changes compared with the zero point, the tower crane is controlled according to the change. In the step S3, the following method is adopted to control the tower crane according to the change: when the infrared signal detected by the sensor at the upper part becomes stronger, and the infrared signal detected at the lower part becomes stronger, the hook of the tower crane is controlled to lift The arm moves near the point; when the infrared signal detected by the upper sensor becomes weak, and the infrared signal detected at the lower part becomes weak, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com