A high-efficiency block forming machine

A block forming machine, high-efficiency technology, applied in the direction of manufacturing tools, supply devices, etc., to achieve the effect of good structural strength, preventing brick height difference, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

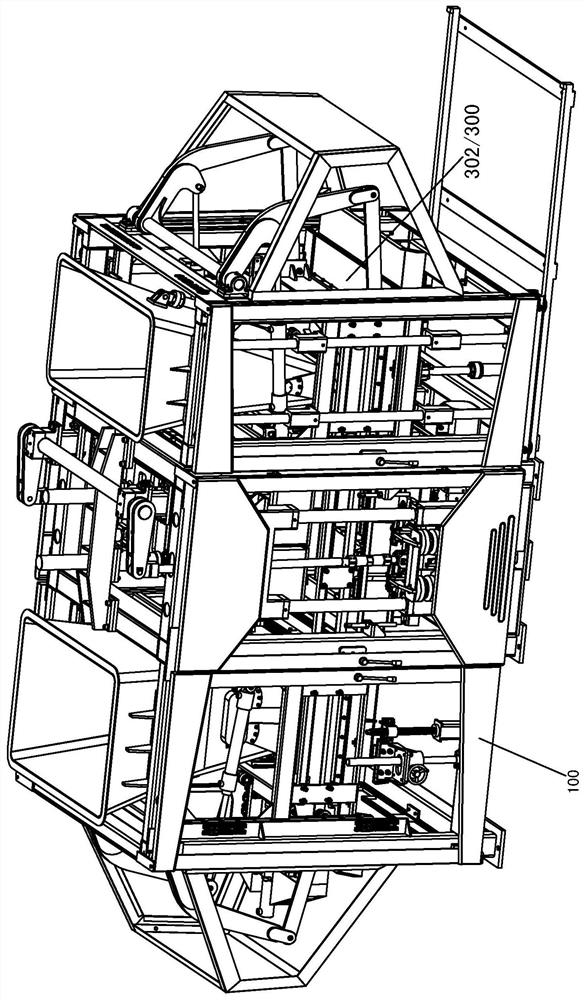

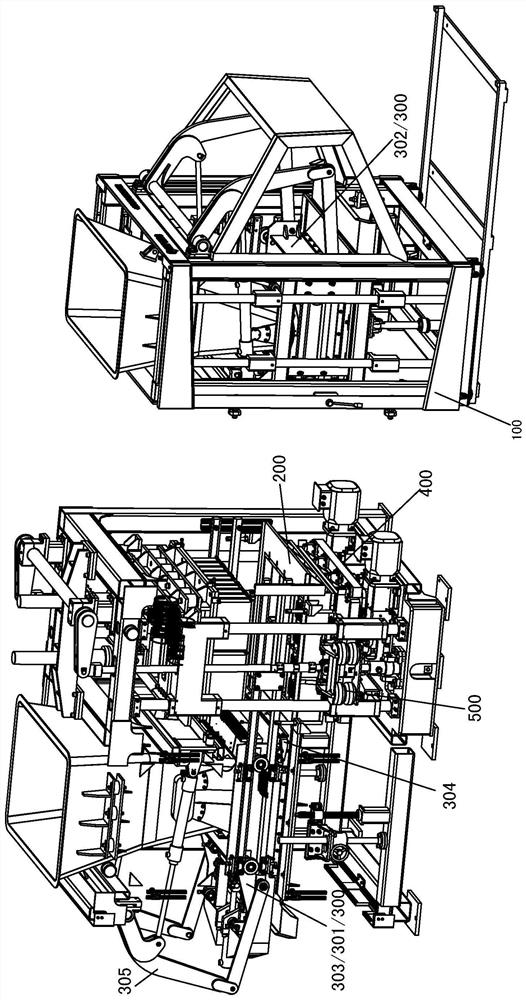

[0067] A high-efficiency block forming machine disclosed in the present invention, such as figure 1 and figure 2 As shown, it mainly includes a frame 100 for erecting various parts of the whole machine, a mold frame 200 for forming bricks, and a distribution cart part 300 for fabricating materials to the mold frame 200 (the distribution cart part 300 shown in the figure includes a fabric distribution cart part 302 and rough material distributing cart part 301), vibrating part 400 for vibrating after distributing, and mold frame lifting part 500 for holding mold frame 200 to drive it up and down.

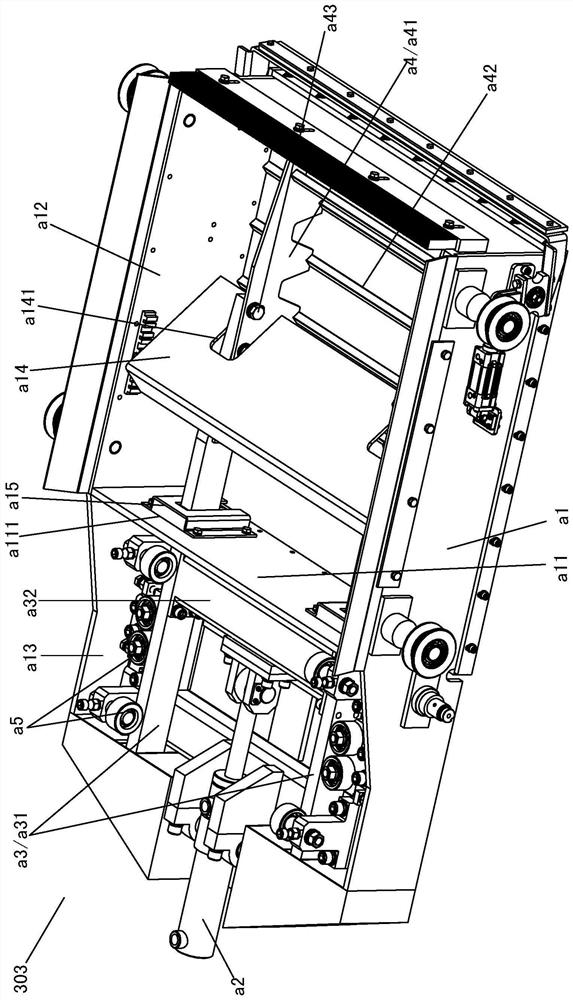

[0068] The distributing cart part 300 includes a distributing cart 303 that can move to the mold frame 200 for distributing. The distributing cart 303 includes a distributing cart frame a1, a push-pull cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com