Plate shearing method and system

A technology of sheet material and shearing mechanism, applied in shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve the problems of high cost of shearing sheet material, difficult to use, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

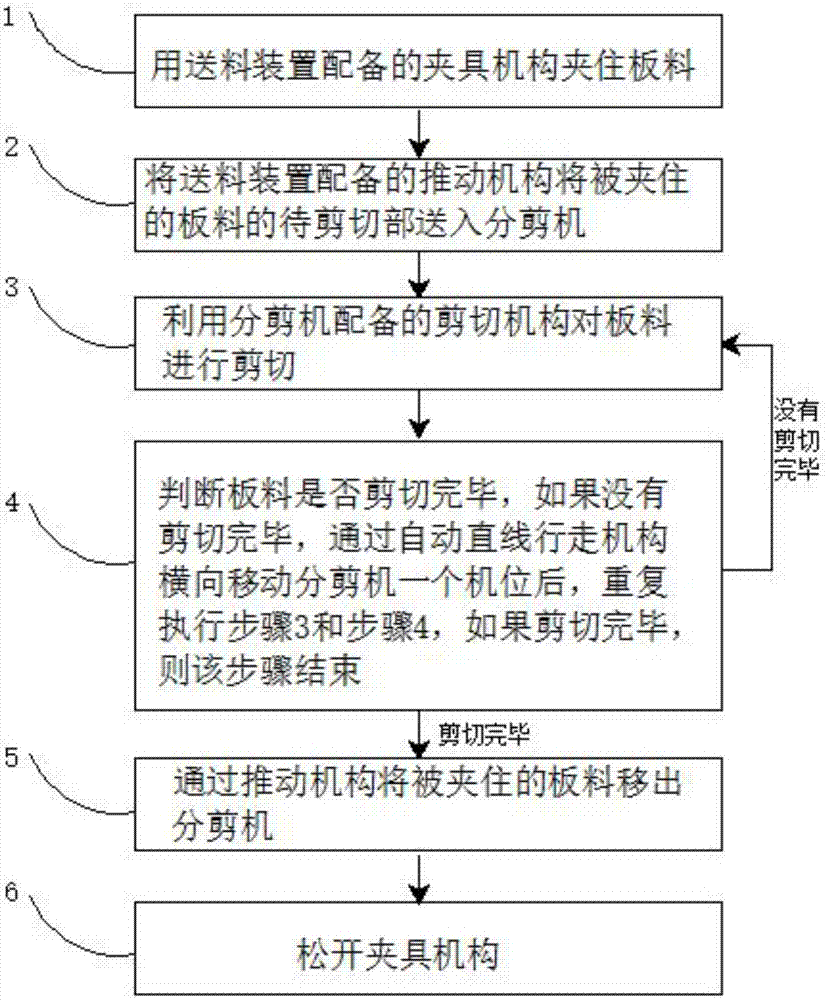

[0052] Such as figure 1 As shown, the sheet metal cutting method provided by Embodiment 1 of the present invention includes:

[0053] Step 1: Use the clamp mechanism equipped with the feeding device to clamp the sheet;

[0054] Step 2: Send the pushing mechanism of the feeding device to the cutting part of the clamped sheet into the cutting machine;

[0055] Step 3: Use the shearing mechanism equipped with the slitter to cut the sheet;

[0056] Step 4: Determine whether the sheet material has been cut. If the cutting is not completed, move the cutting machine one position laterally through the automatic linear walking mechanism, and repeat steps 3 and 4. If the cutting is completed, the step ends;

[0057] Step 5: Move the clamped sheet out of the cutting machine through the pushing mechanism;

[0058] Step 6: Loosen the clamp mechanism.

[0059] By moving the splitting machine laterally, the large-width sheet material is cut in sections and cut into parts, which effectively overcomes the...

Embodiment 2

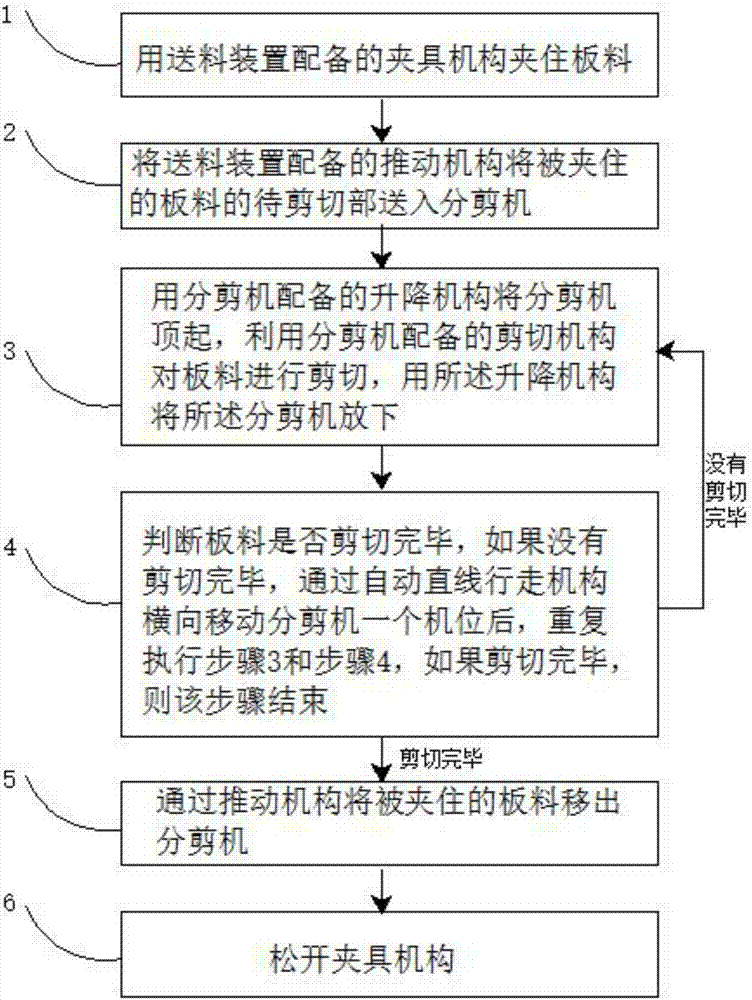

[0061] Such as figure 2 As shown, the sheet metal cutting method provided by Embodiment 2 of the present invention includes:

[0062] Step 1: Use the clamp mechanism equipped with the feeding device to clamp the sheet;

[0063] Step 2: Send the pushing mechanism of the feeding device to the cutting part of the clamped sheet into the cutting machine;

[0064] Step 3: Use the lifting mechanism equipped with the shearing machine to lift up the shearing machine, use the shearing mechanism equipped with the shearing machine to cut the sheet, and use the lifting mechanism to lower the shearing machine.

[0065] Step 4: Determine whether the sheet material has been cut. If the cutting is not completed, move the cutting machine one position laterally through the automatic linear walking mechanism, and repeat steps 3 and 4. If the cutting is completed, the step ends;

[0066] Step 5: Move the clamped sheet out of the cutting machine through the pushing mechanism;

[0067] Step 6: Loosen the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com