High-temperature thermal power spinning heating method and device

A heating device and heating method technology, applied in metal processing, metal processing equipment, forming tools, etc., can solve the problems of poor temperature control ability, unable to meet heating requirements, unable to achieve better temperature stability, etc. The effect of strong spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

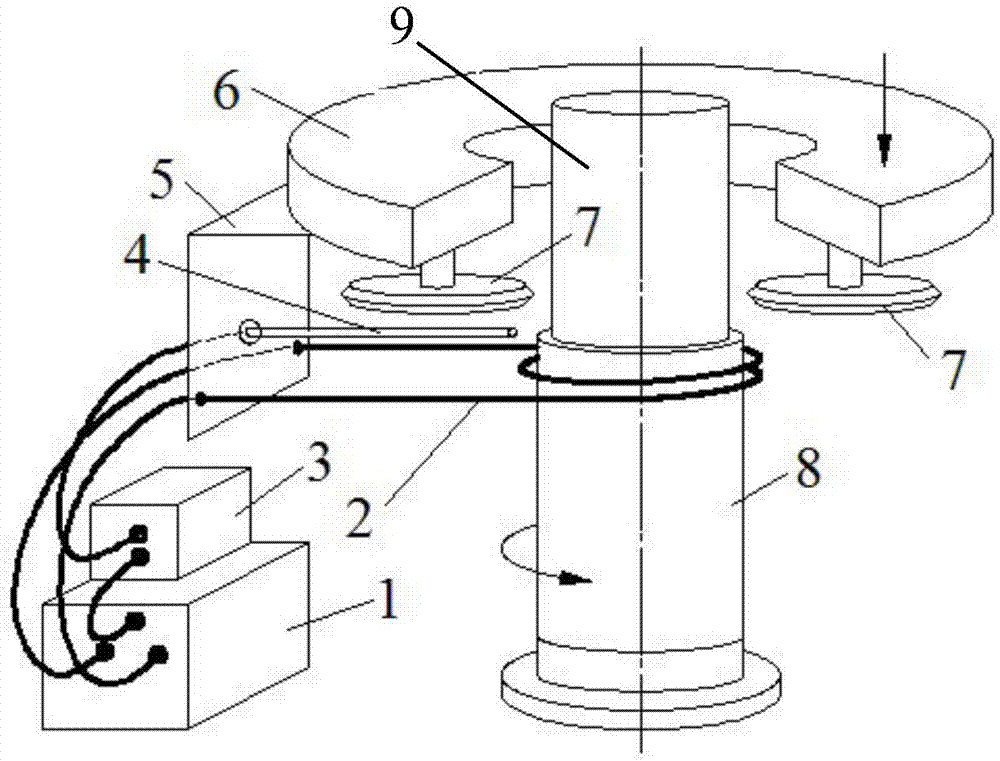

[0026] like figure 1 shown. The invention discloses a high-temperature heat and strong spinning heating device, which includes several rotary wheels 7 installed around the rotary wheel frame 6, a spinning mandrel 9 for installing a tube blank 8; the spinning mandrel 9 is used for feeding the tube The blank 8 provides support, and the rotary wheel 7 is used to provide radial pressure to the tube blank 8 from the outside to the inside; when the rotary wheel frame 6 moves from top to bottom, the rotary wheel 7 is in contact with the outer wall of the tube blank 8, and Under the rotation of the tube blank 8, a radial spinning force is provided to the tube blank 8 through the rotary wheel 7;

[0027] The high-temperature heat and strong rotation heating device also includes an annular induction coil 2 and an infrared temperature measuring head 4 that are installed on the wheel frame 6 and move up and down synchronously with the wheel frame 6;

[0028] The annular induction coil 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com