Modular sub-bench set

A sub-table, modular technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problem of unable to meet the rapid positioning and clamping of multi-variety small batch non-standard parts, unable to achieve rapid reset switching, cycle time Long and other problems, to achieve the effect of excellent function, low cost and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific implementations are now described in detail with reference to the accompanying drawings.

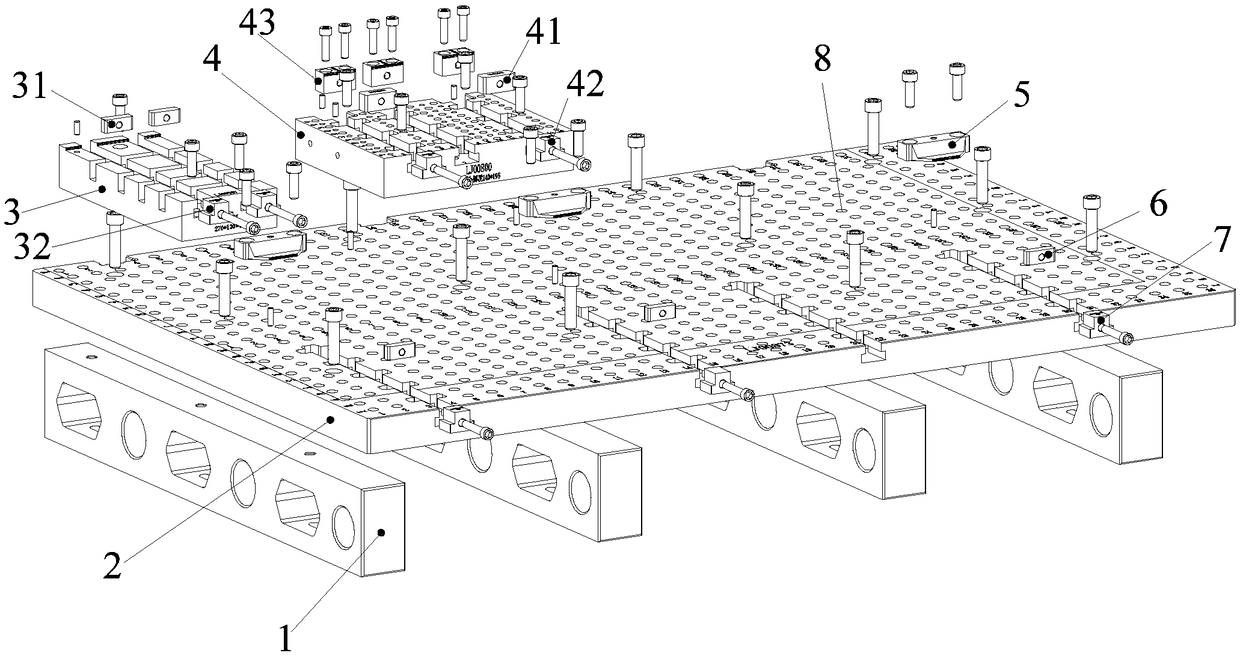

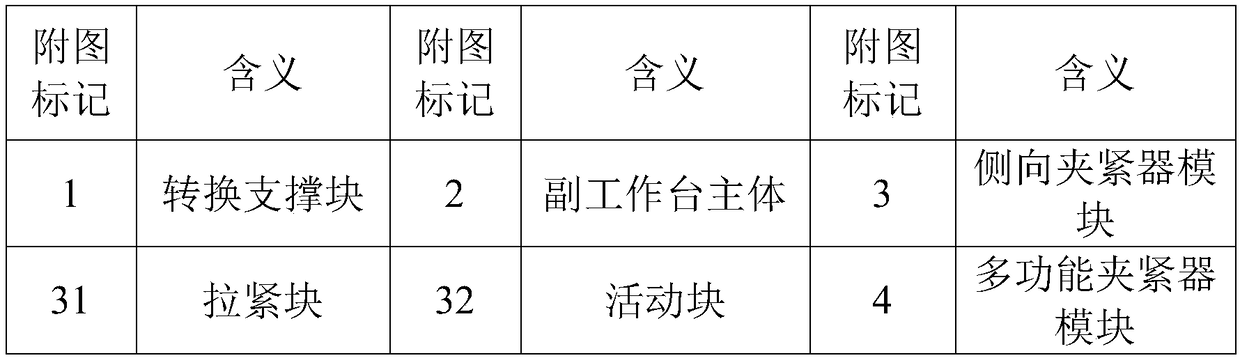

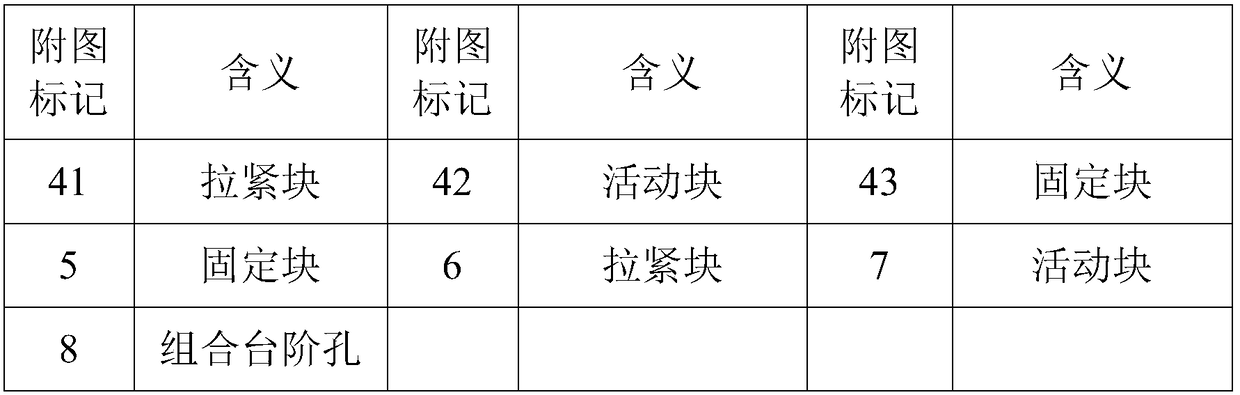

[0030] Such as figure 1 As shown, the modular auxiliary workbench group includes a conversion support block 1 for installation and cooperation with the work surface of a machine tool, and a sub-workbench main body 2 connected and assembled on it. The sub-workbench main body 2 is locked and fixed to the conversion by internal hexagonal screws. On the support block. The working surface of the main body 2 of the auxiliary workbench is respectively provided with a combined step hole 8 composed of positioning pin holes and a locking screw hole, which are equally spaced. The single-sided position accuracy of the combined step hole 8 is within 0.01mm, and the spatial position accuracy is within 0.02mm. , The working surface of the sub-workbench main body 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com