A vertical banana stalk crushing and returning machine

A banana stalk and vertical technology, which is applied in the field of vertical banana stalk crushing and returning machines, can solve the problems of straw resource waste, time-consuming, efficiency reduction, etc., to prevent resource waste and environmental degradation, and facilitate maintenance and replacement , The effect of saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments.

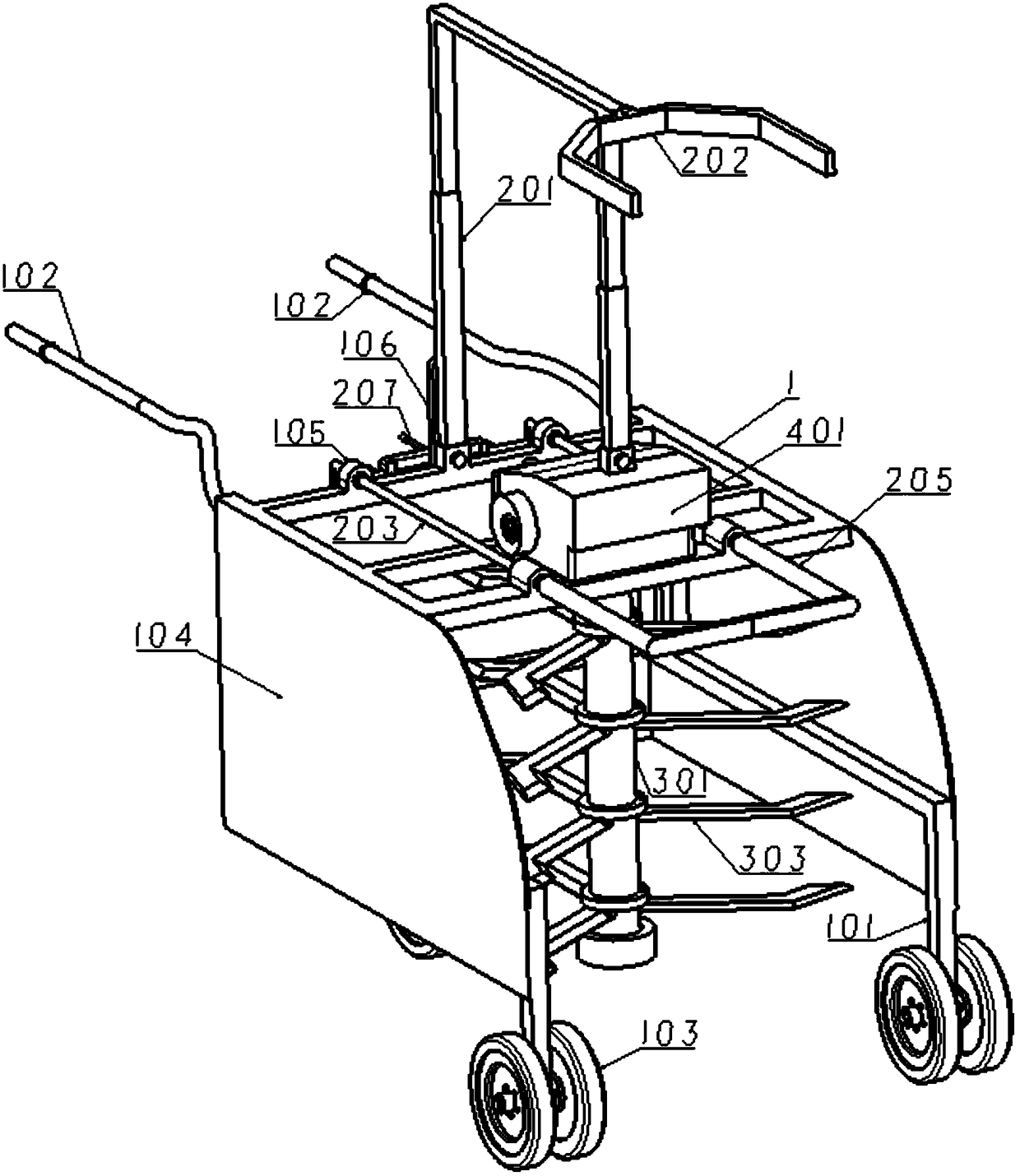

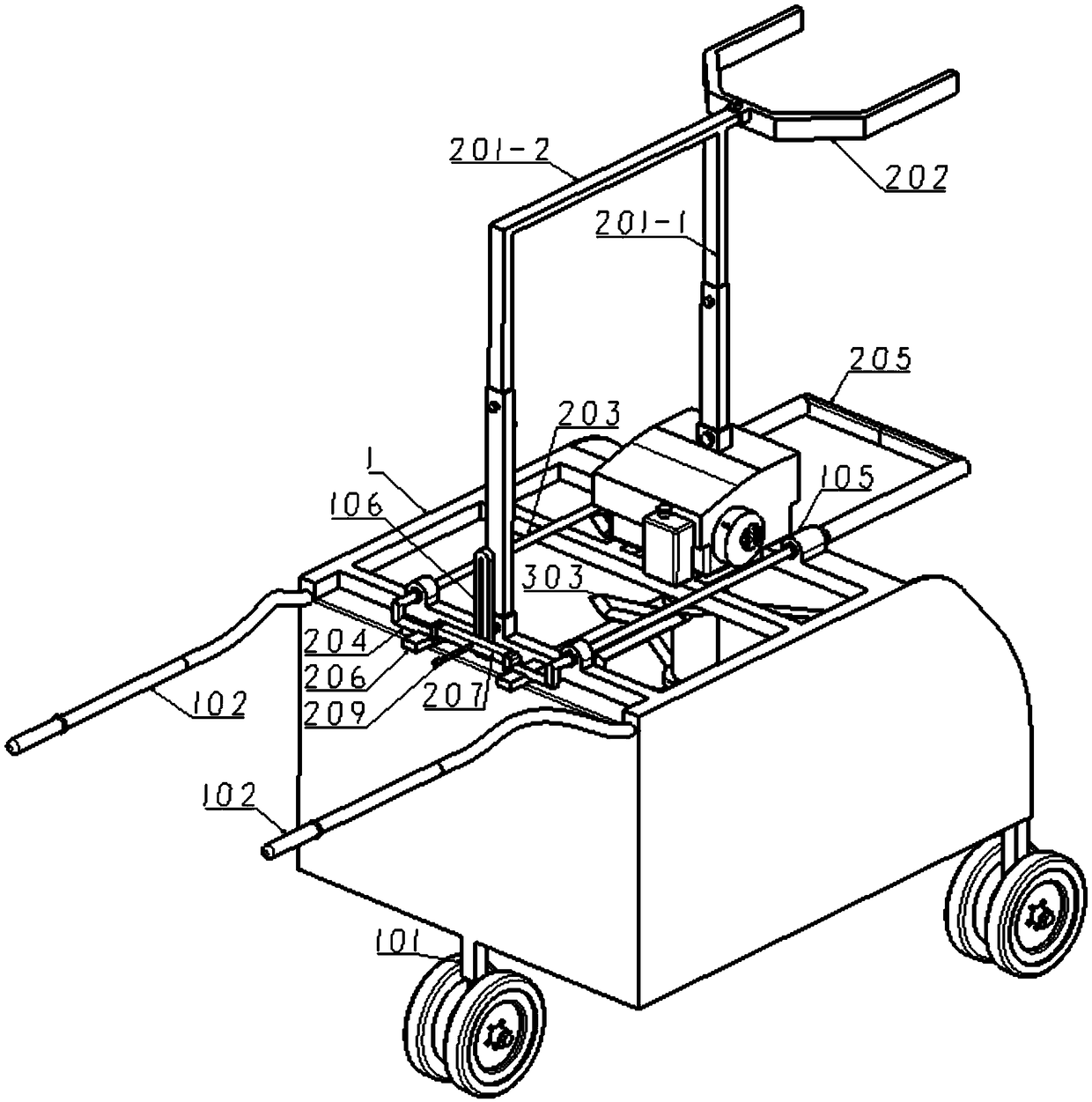

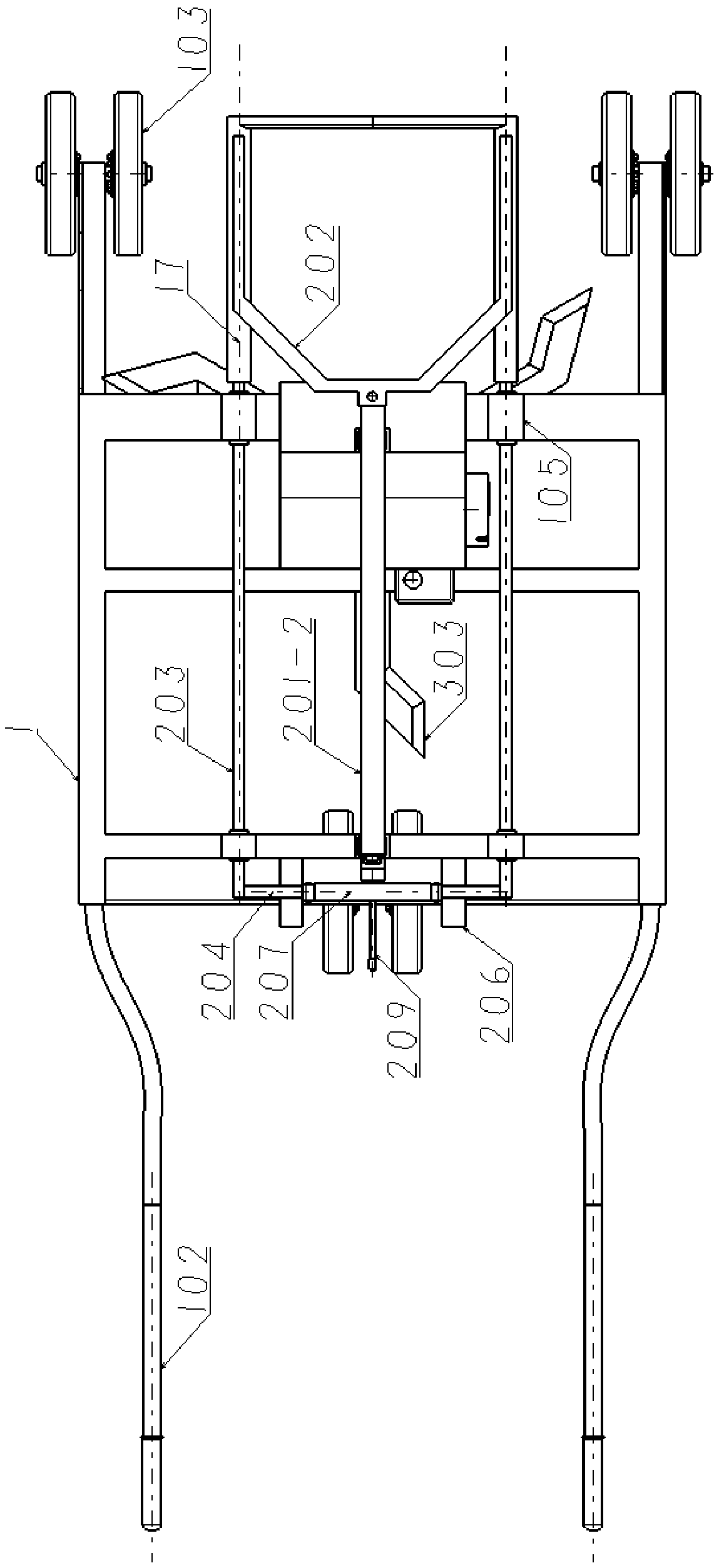

[0027] See Figure 1 to Figure 10 As shown, the vertical banana stalk crushing and returning machine provided in this embodiment includes a frame 1, a limit mechanism, a vertical crushing cutter, and a transmission device mounted on the frame. The frame 1 is formed with three supporting feet 101 to form a three-point supporting structure, and two hand push handles 102 extend back, and wheels 103 are installed at the bottom of each supporting foot 101 for walking or turning. For safety considerations, protective plates 104 are installed on the left and right sides and the rear of the rack 1. The limit mechanism includes an upper limit unit, a lower limit unit, and a limit switch. The upper limit unit includes a telescopic bracket 201 and a U-shaped arm 202. The telescopic bracket 201 is an inverted U-shaped structure and consists of two vertical telescopic A rod 201-1 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com