Transmission mechanism provided with wedge sliding block

A technology of a wedge slider and a transmission mechanism is applied in the field of stamping devices, which can solve the problems of large occupied space and complex structure, and achieve the effects of simplified structure and low manufacturing and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

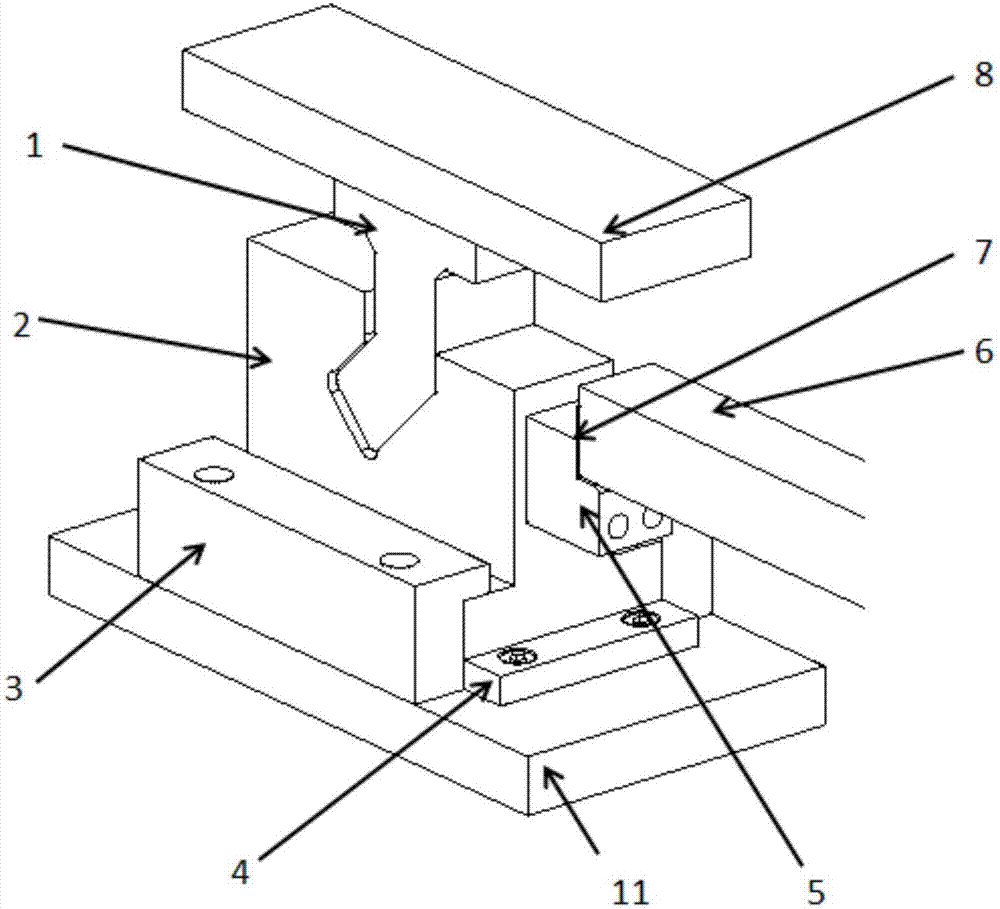

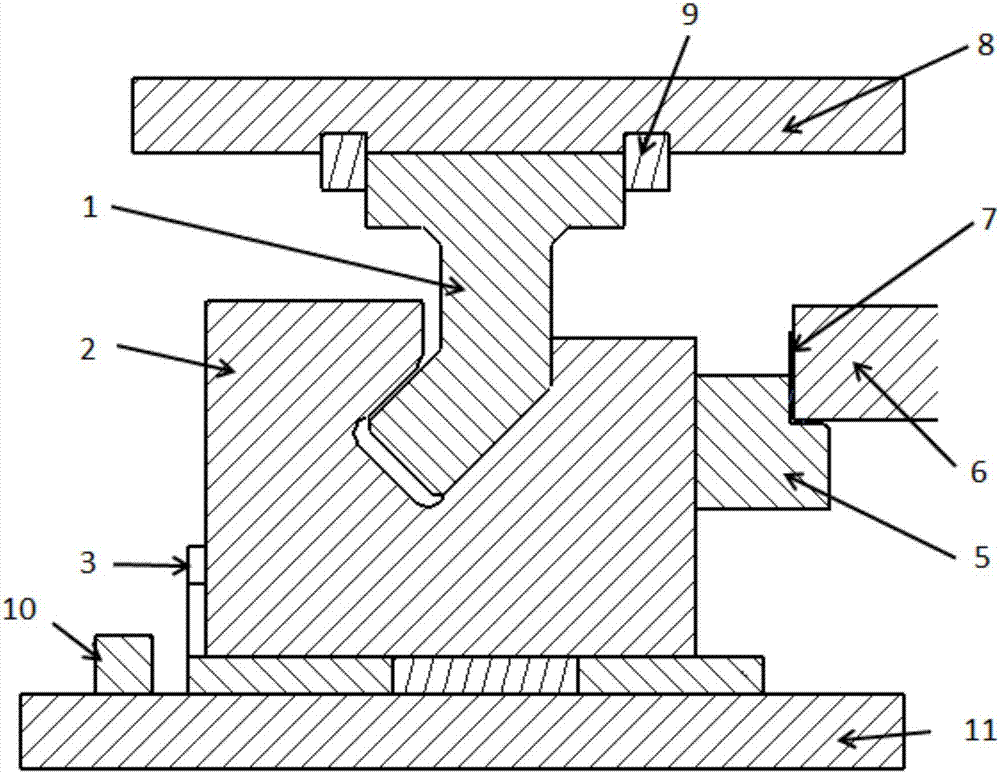

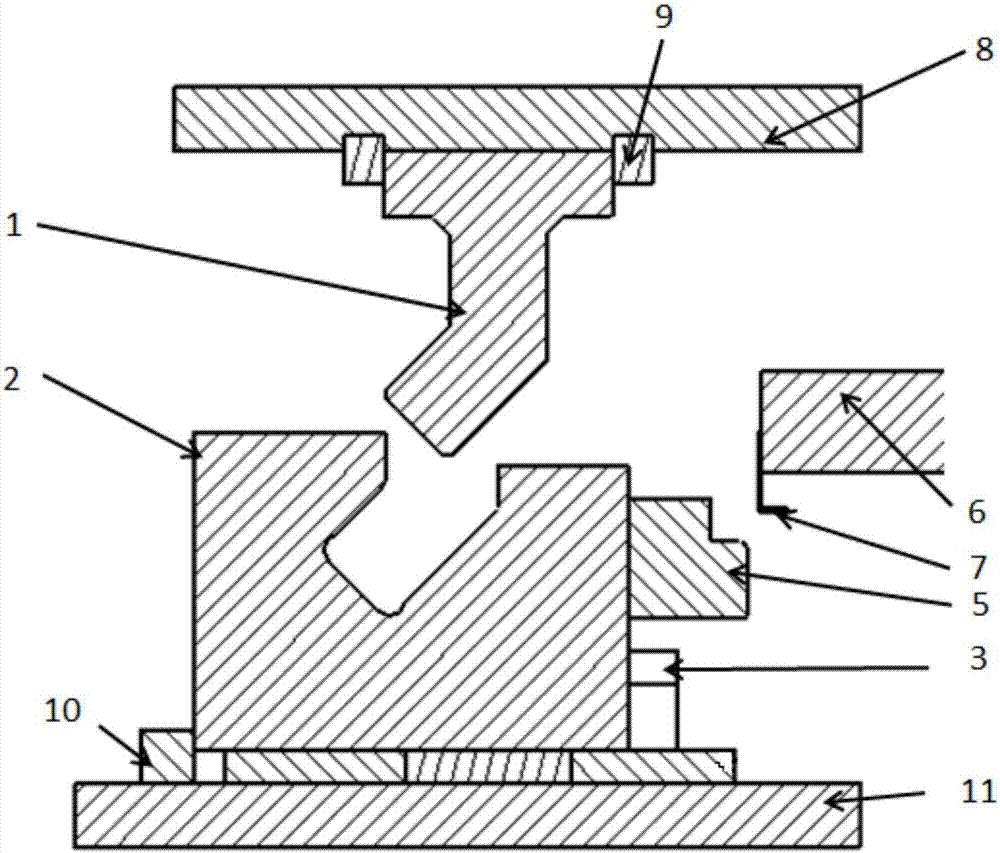

[0031] Realized by setting limit blocks on both sides of the wedge slider 2, combined with figure 1 and figure 2 As shown, specifically, a limit block is protruded from the lower template 11 on both sides of the wedge slider 2 along its moving direction, specifically the front limit block 4 on the front side and the rear limit block 10 on the rear side. , the wedge slider 2 moves between the two limit blocks, and the limit block limits the front and rear displacement of the wedge slider, so that the guide groove 21 opened on the wedge slider 2 faces the drive block 1 all the time.

Embodiment 2

[0033] It is realized by setting the width of the guide groove 21 and the angle between the driving block 1 and the guide groove 21 . That is, in this embodiment, the guide groove 21 has a predetermined width. At this time, it should be ensured that the angle formed by the driving section of the driving block 1 and the driving direction of the upper template is an acute angle. The same, so the angle of its bending is also an acute angle. The adoption of the acute angle does not cause the mold to be too large to waste material, and when the drive block 1 cooperates with the guide groove 21, the lateral sliding distance of the wedge slider 2 will not be too large. Of course, Embodiment 1 and Embodiment 2 can also be used simultaneously to ensure that the bottom end of the drive block is always facing the opening of the guide groove.

[0034] Such as Figure 5 As shown, in the present embodiment, the guide groove 21 includes a vertical guide groove at the top and an inclined dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com