Full-automatic attaching machine of motor frame

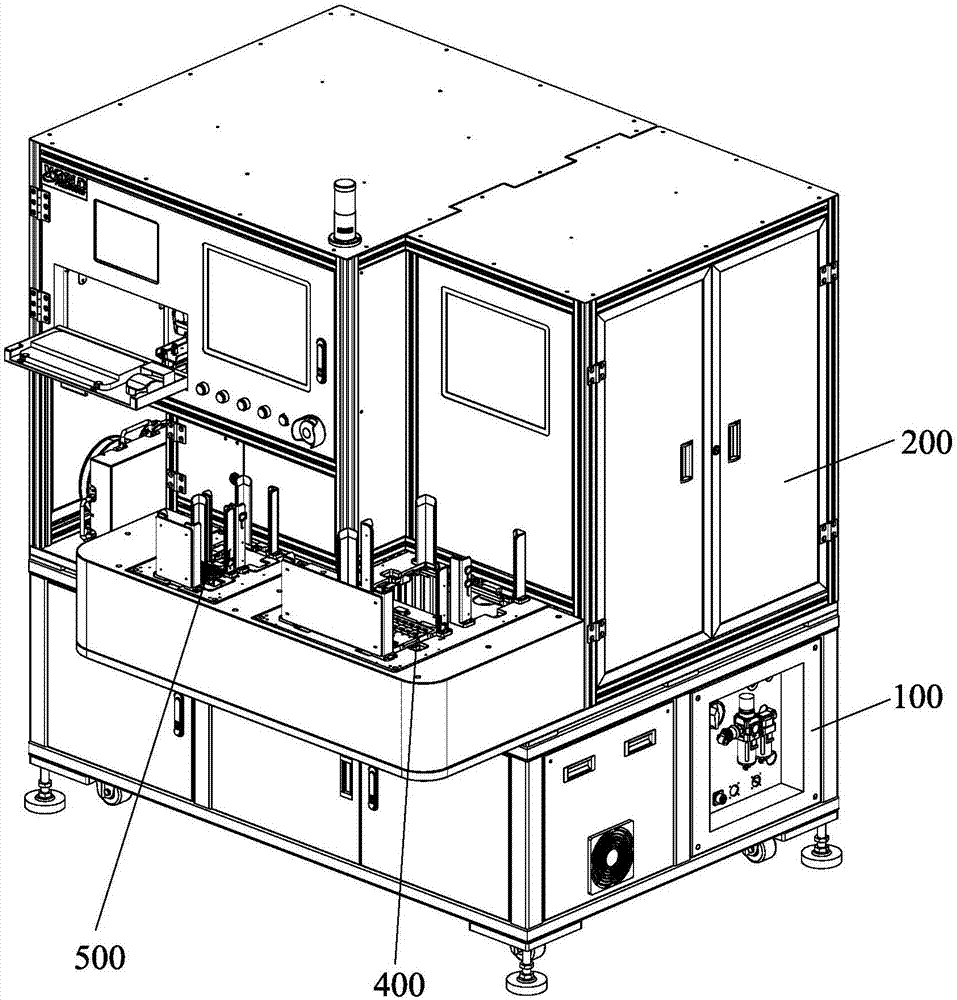

A laminating machine and fully automatic technology, which is applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of low manual operation efficiency and inability to improve production quality, and achieve high production efficiency, high production quality and layout compact and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

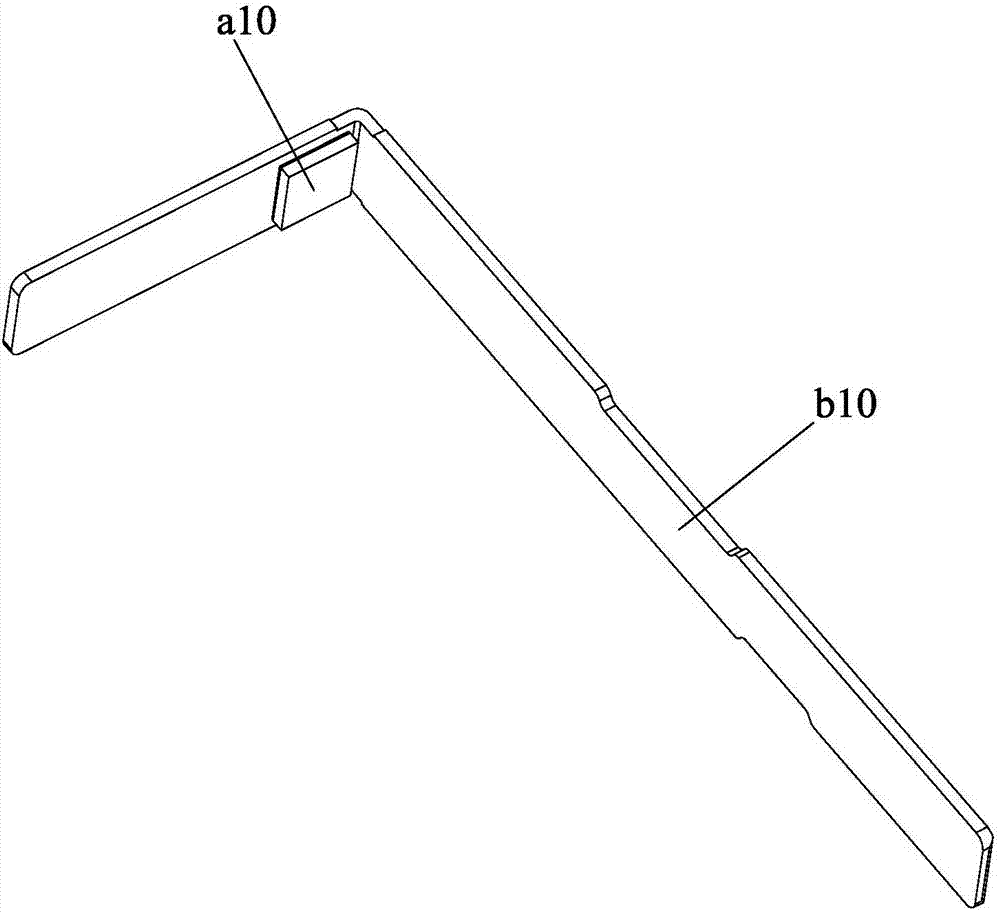

[0033] Such as figure 1 The L-shaped frame b10 shown is used to be arranged on the outside of the vibration motor of the mobile phone. Specifically, the rectangular frame structure formed by combining the same two frames b10 forms a surrounding frame in the vibration direction around the vibration motor of the mobile phone. In order to reduce the impact force of the vibration motor of the mobile phone, a buffer block a10 needs to be arranged on the inner side of the frame b10 towards the vibration direction of the vibration motor of the mobile phone. Generally, the buffer block a10 includes a buffer function part for realizing a buffer function and a connecting part provided on one side of the buffer function part for realizing connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com