Discrete type work shop production process management system

A production process and management system technology, applied in the direction of data processing applications, instruments, resources, etc., can solve the problems of information faults between the planning layer and the control layer, failure to realize the monitoring of the workshop manufacturing process, and blocking of enterprise production and operation information, etc., to achieve guaranteed Real-time, small batch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

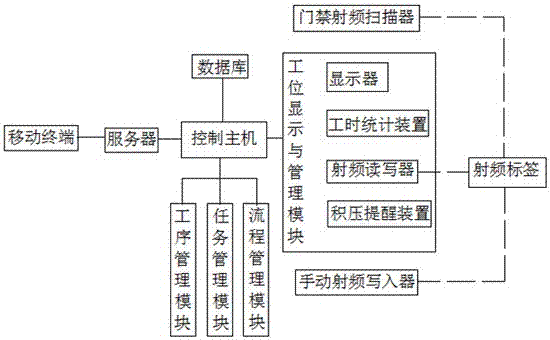

[0018] Such as figure 1 A discrete workshop production process management system shown includes a control host, servers connected to the control host, a database, a task management module, a process management module, a process management module, a station display and management module, and a radio frequency Labels, manual radio frequency writing equipment and mobile terminals; the station display and management module is set at each station, including a display and a station management unit, and the station management unit includes a working hour statistics device, a backlog reminder device and a radio frequency reader writer; the mobile terminal is connected to the server through a wireless network; wherein:

[0019] Step 1. The order enters the database. After the workshop receives an order, it first stores all the technical drawings and technological processes related to the order in the database, including detailed pictures of each part and assembly drawings; the database...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com