Construction method for basement exterior wall thermal-insulating and waterproof protective layer

A technology of basement exterior wall and construction method, applied in wine cellars, building components, buildings, etc., can solve the problems of basement exterior wall leakage, protection wall deformation, waterproof layer damage, etc., so as to reduce impact force and ensure quality , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

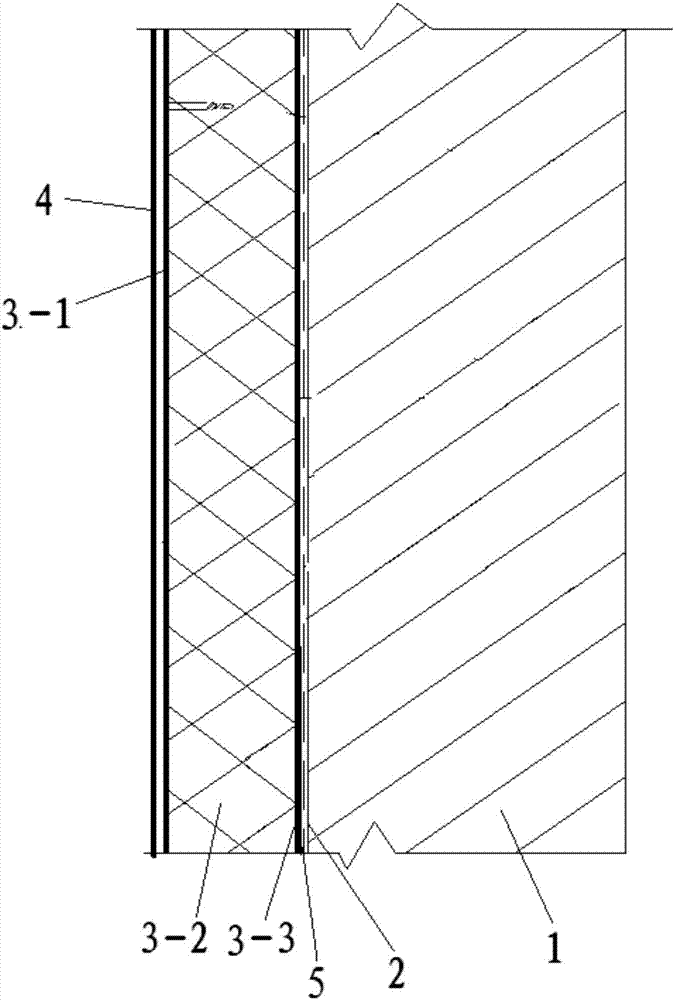

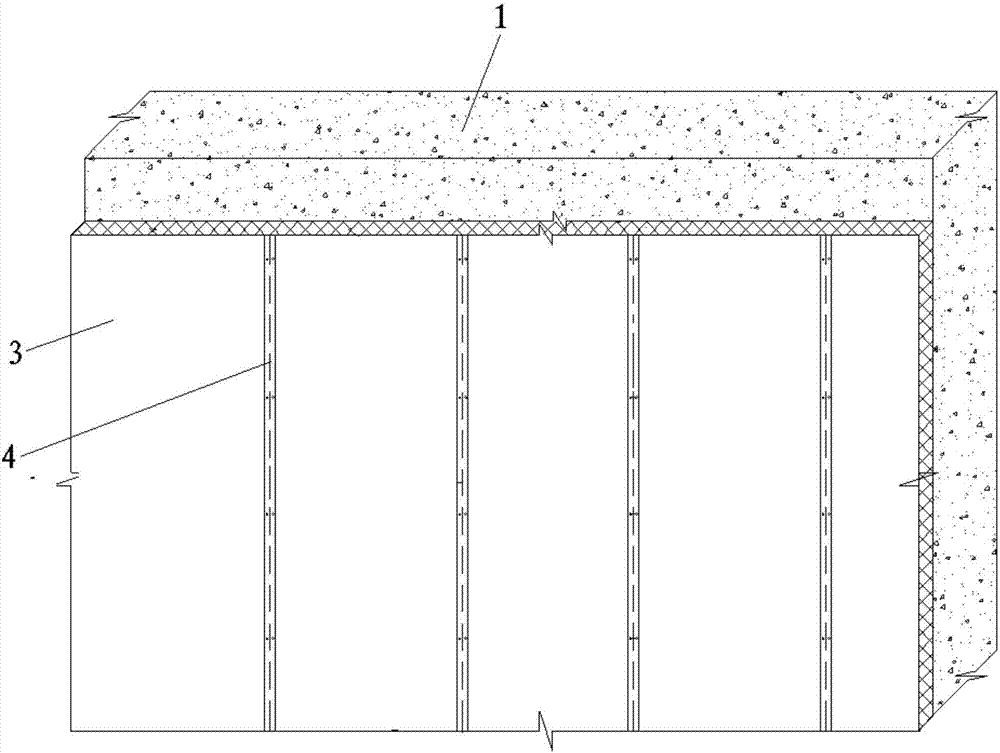

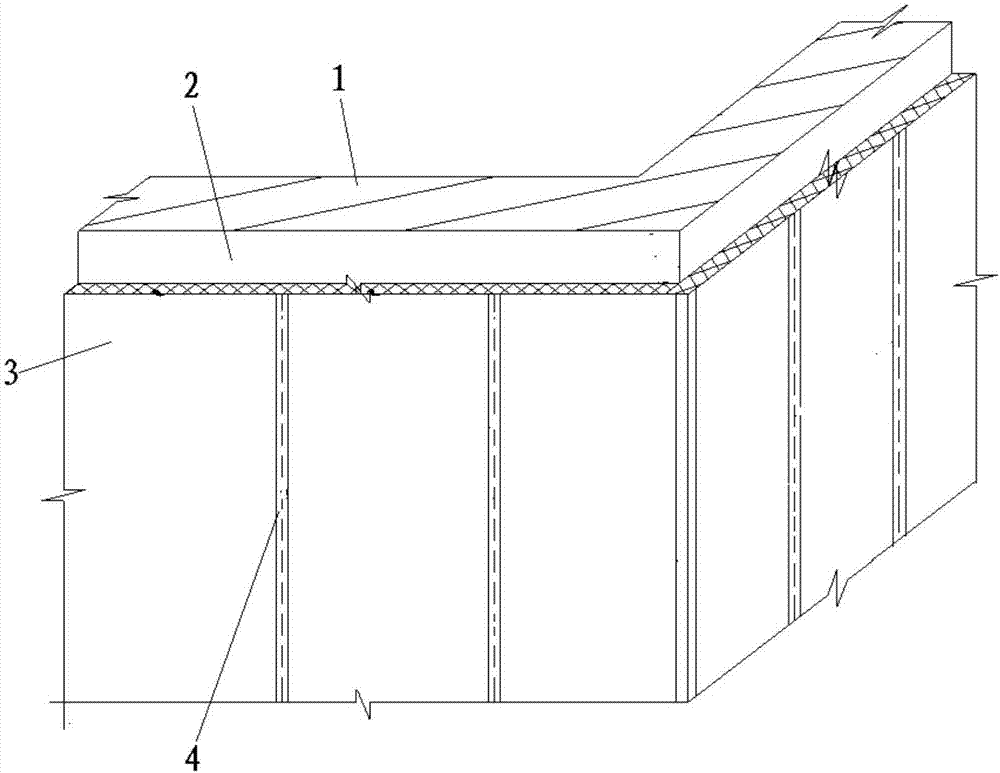

[0033] The construction method of the basement exterior wall thermal insulation and waterproof protective layer comprises the following steps: A. Prepare a rectangular waterproof protective layer 3, the waterproof protective layer 3 includes an inner layer 3-3, a middle layer 3-2 and an outer layer that are sequentially arranged and bonded 3-1, the inner layer 3-3 and the outer layer 3-1 are made of steel plates, and the middle layer 3-2 is made of XPS or EPS; B. Check the smoothness of the surface of the waterproof layer 2 of the outer wall, if not, use cement Filling with mortar; C, setting an adhesive 5 on the surface of the outer wall waterproof layer 2 for pasting a waterproof protective layer 3; D, standing a waterproof protective layer 3 and pasting it on the outer wall waterproof layer 2, waterproof protection The laminate 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com