Self-generating foam kill fluid and preparation method and self-generating foam composition

A self-generating foam and composition technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as difficult to achieve stirring speed, limited lifting space, easy to explode, etc., to achieve convenient preparation, low damage, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

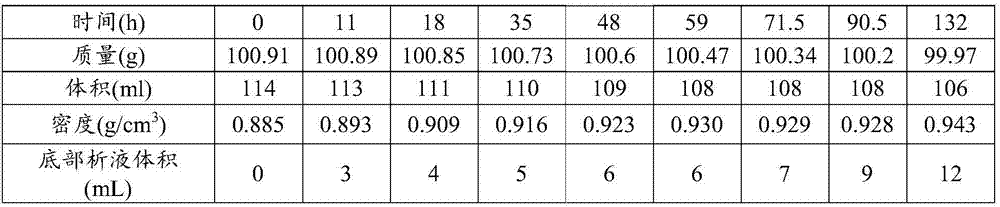

Examples

preparation example Construction

[0026] A preparation method of the self-generating foam well killing fluid includes: mixing the foaming agent after stirring and foaming with a polymer and a crosslinking agent to obtain a gel material. The gel material is then mixed with the gas generating agent.

[0027] Among them, the gel material is a high-deformation gel that does not flow or almost does not flow. According to the ten-grade evaluation standard for plugging agent gel strength proposed by Sydansk et al., it belongs to grades E to F. The gel at this strength is more suitable for mixing in the gas phase to obtain a well-killing fluid with good elasticity and moderate viscosity, which is conducive to the establishment of wellbore circulation during well-killing operations.

[0028] It is worth noting that, in addition to the above methods, the foaming agent can also be stirred uniformly until a certain foam is obtained, and then the polymer, crosslinking agent and gas generating agent are added in sequence an...

Embodiment 1

[0031] This embodiment provides a self-generating foam composition, which includes: polyacrylamide 3wt%, alkyl glucoside and sodium dodecylsulfonate 2wt%, chromium acetate 0.1wt%, polyethyleneimine 1wt%, acid substances (malic acid and citric acid) 0.021mol / L, carbonate (anhydrous sodium carbonate and sodium bicarbonate) 0.021mol / L and the balance of deionized water.

[0032] This embodiment also provides a self-generating foam kill fluid prepared from the above-mentioned self-generating foam composition, the preparation method of which comprises:

[0033] S1: Add alkyl glucoside, polyacrylamide, chromium acetate and polyethyleneimine in sequence in deionized water, and stir evenly with a glass rod to obtain a gel material;

[0034] S2: Mix the above-mentioned gel material with malic acid and anhydrous sodium carbonate, and stir evenly with a glass rod to obtain the autogenous foam killing fluid.

Embodiment 2

[0036]This embodiment provides a self-generating foam composition, which includes: polyacrylamide 3wt%, betaine and sodium dodecylbenzenesulfonate 4wt%, chromium acetate 0.2wt%, polyethyleneimine 2wt%, acid substances (malic acid and dihydrate oxalic acid) 0.034mol / L, carbonate (anhydrous sodium carbonate and ammonium bicarbonate) 0.034mol / L and the balance of deionized water.

[0037] This embodiment also provides a self-generating foam kill fluid prepared from the above-mentioned self-generating foam composition, the preparation method of which comprises:

[0038] S1: Add betaine, polyacrylamide, chromium acetate and polyethyleneimine in sequence in deionized water, and stir evenly with a glass rod to obtain a gel material;

[0039] S2: Mix the above-mentioned gel material with malic acid and anhydrous sodium carbonate, and stir evenly with a glass rod to obtain the autogenous foam killing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com